An engine transport fixing bracket

A technology for fixing brackets and engines, which is applied in transportation and packaging, assembly machines, external frames, etc. It can solve the problems of single use, failure to meet the requirements of precision engine transportation and shock absorption, poor shock absorption effect of engine brackets, etc., to reduce impact Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific embodiment of the present invention is:

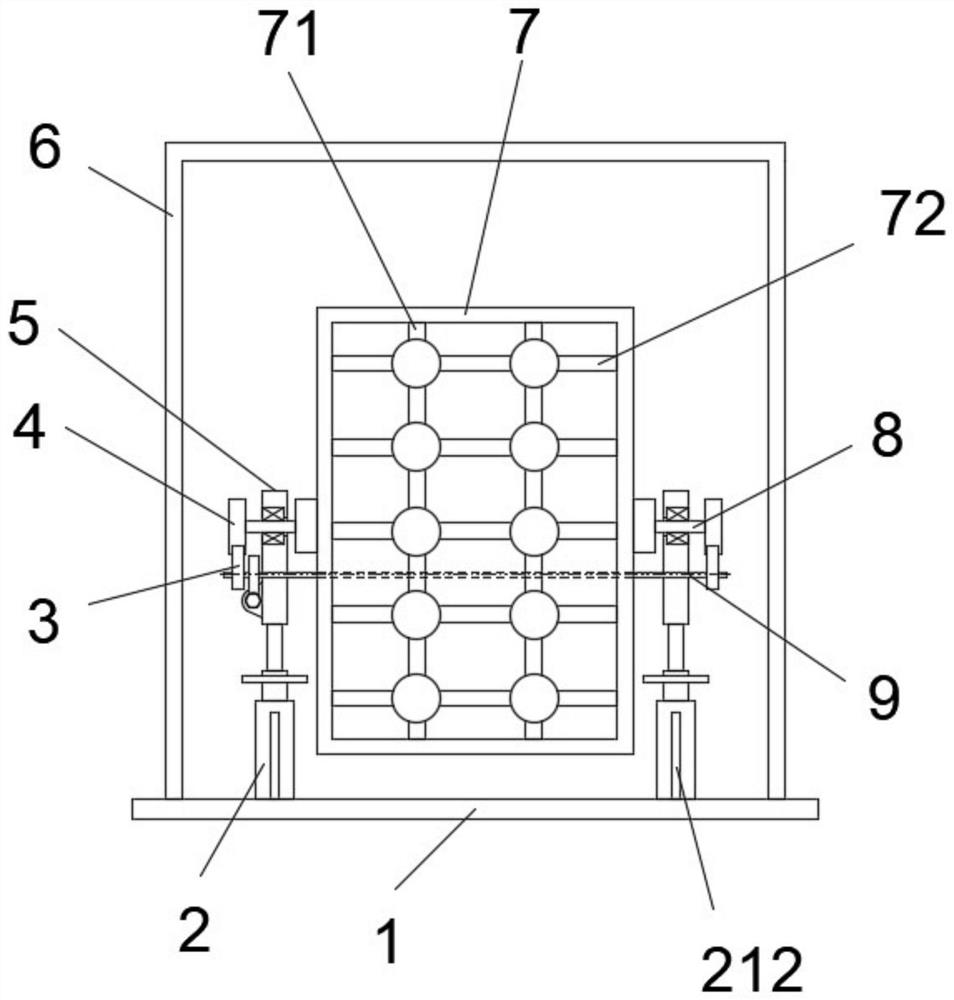

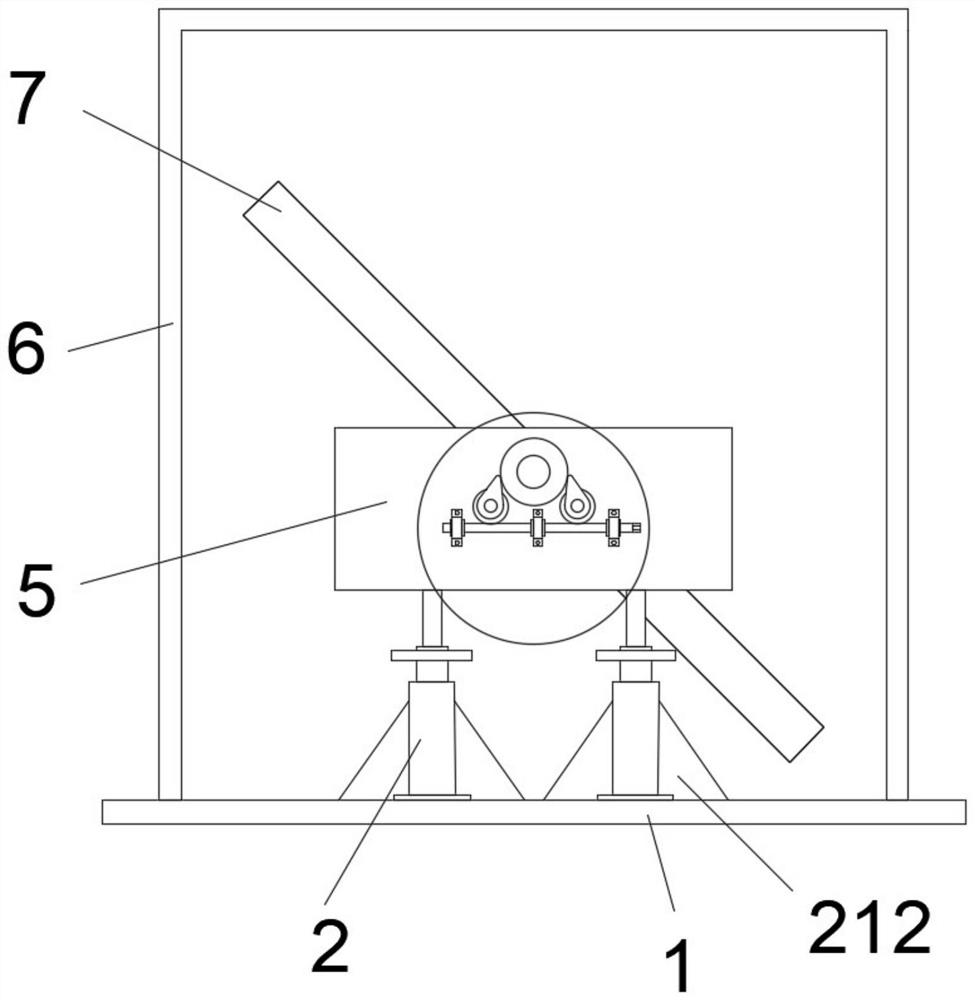

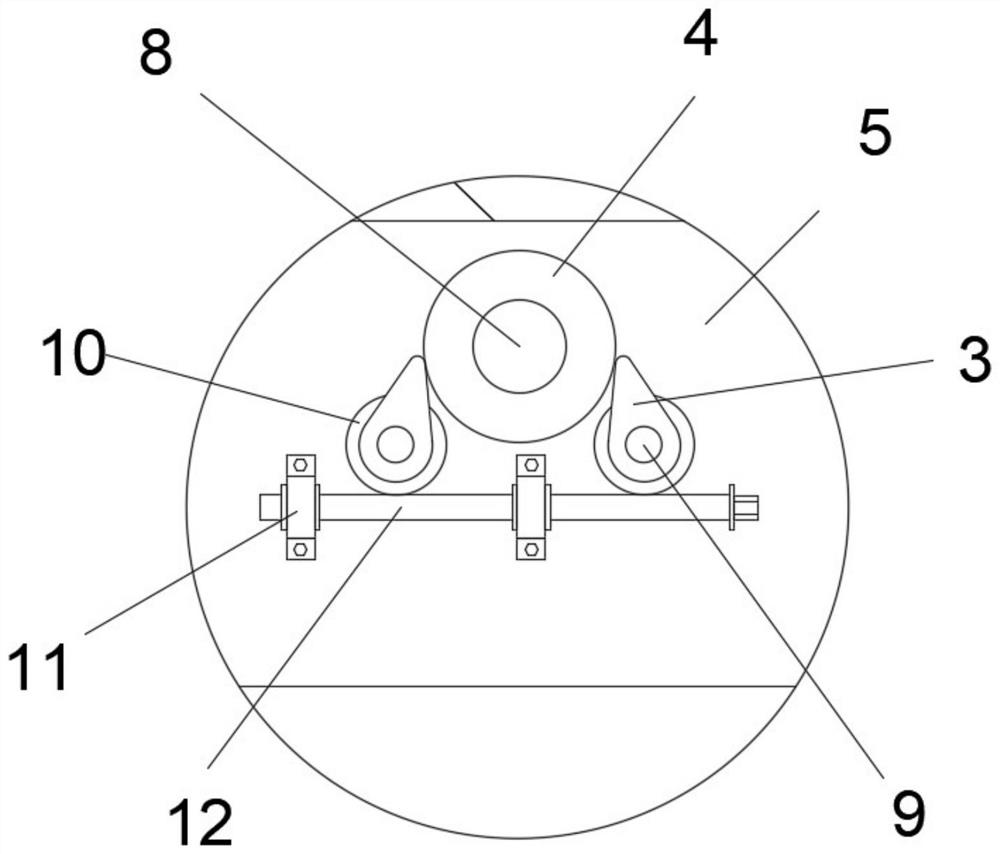

[0024] see Figure 1-5 As shown, a fixed bracket for engine transportation includes a turret, a mounting plate 1, a support plate 5, a shock absorber 2, and a rotating shaft 8; the mounting plate 1 is provided with a safety cover 6; the engine is formed by the safety cover 6 protection; the turret, the support plate 5, the shock absorber 2, and the rotating shaft 8 are arranged in the safety cover 6; the mounting plate 1 is provided with two support plates 5; the mounting plate 1 and the support plate 5 A shock absorber 2 is arranged between them; the rotating shaft 8 is rotatably connected to the two support plates 5; the rotating frame 7 is arranged on the rotating shaft 8; the engine is fixed on the rotating frame 7; the rotating shaft 8 Both sides of the friction wheel 4 are provided with friction wheels 4; both sides of the friction wheel 4 are provided with friction cams 3; two friction cams 3 and friction wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com