Method for improving evaluation efficiency of mussel adhesion resistance of material

A technology for adhesion performance and mussels, which is applied in the field of corrosion to achieve the effect of improving evaluation efficiency and quantifying evaluation results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

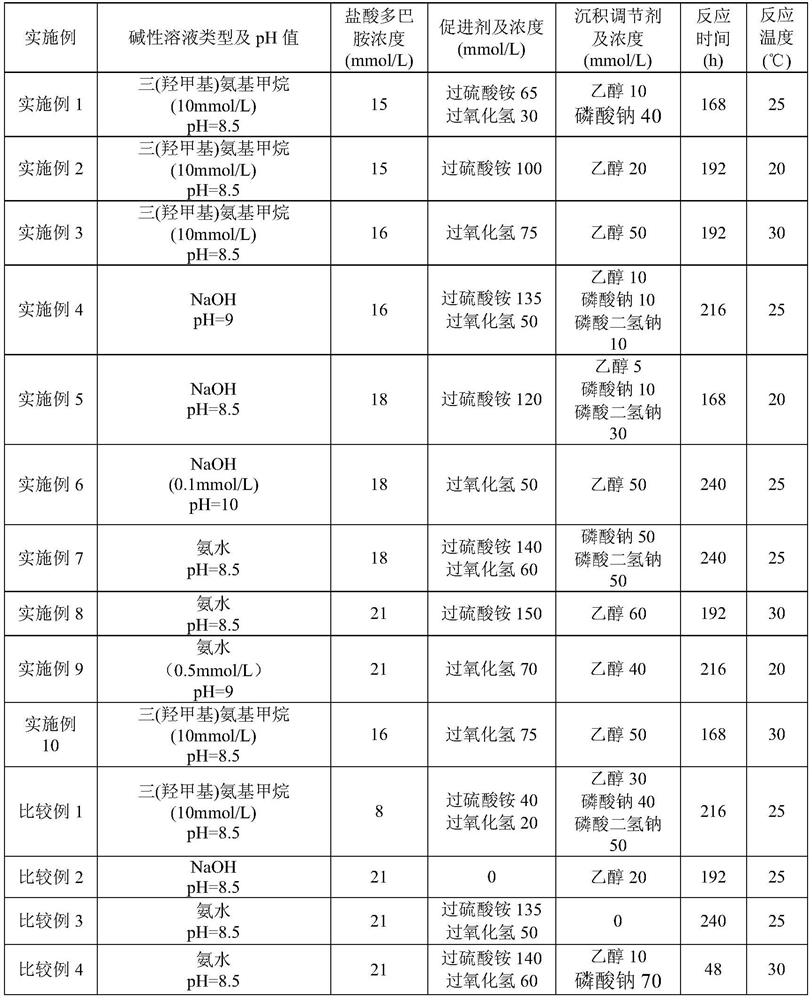

[0019] See Table 1 for an embodiment and a comparative example of a method for improving the evaluation efficiency of the material's anti-mussel adhesion performance of the present invention. The material used in Examples 1-9 and Comparative Example is marine steel AH32, and the material used in Example 10 is polytetrafluoroethylene. The concrete effect of embodiment and comparative example is shown in table 2.

[0020] The embodiment of the present invention and comparative example of table 1

[0021]

[0022]

[0023] Table 2 embodiment and comparative example effect

[0024]

[0025] Remarks: ○-the deposition layer has uniform color and uniform film thickness distribution; △-the deposition layer has relatively uniform color and luster and film thickness distribution;

[0026] ×—The deposition layer has uneven color and uneven film thickness distribution.

[0027] It can be seen from the implementation effects of each embodiment that according to the technical so...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap