Battery OCV detection equipment and detection method thereof

A technology for testing equipment and batteries, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problems of discontinuity, labor consumption, and increased labor costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

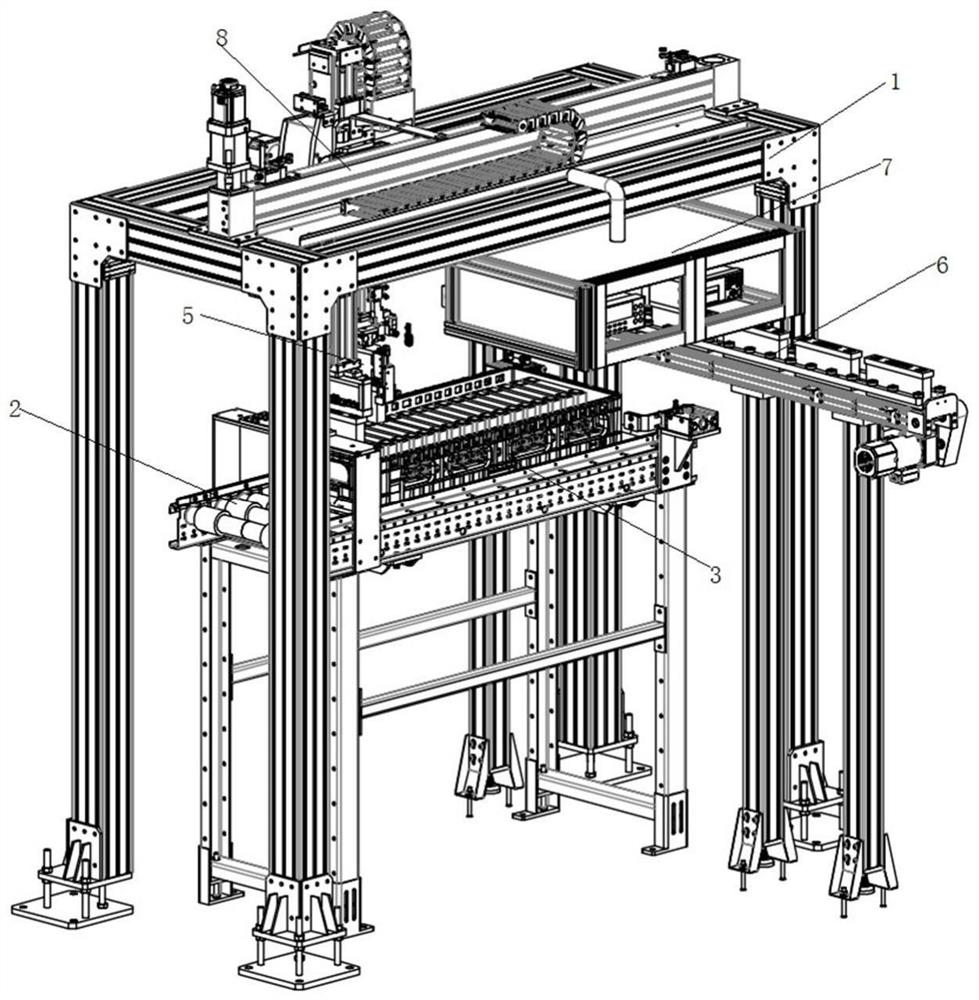

[0051] Such as figure 1 As shown, the frame 1 is used to be placed on the ground to install and support other components of the testing equipment. The drum wire body unit 2 is located in the frame 1, the drum wire body unit 2 includes a driving part and a wire body part, and the driving part is used to drive the transportation of the wire body part; the drum wire body unit 2 It can be realized by the more commonly used conveying rollers in the prior art, so it will not be described in detail. It also includes a battery 4 tray 3 placed on the line body, and the battery 4 tray 3 is used to arrange and collect the batteries 4 in an orderly manner; the battery 4 tray 3 is removed under the action of the line body Send transport.

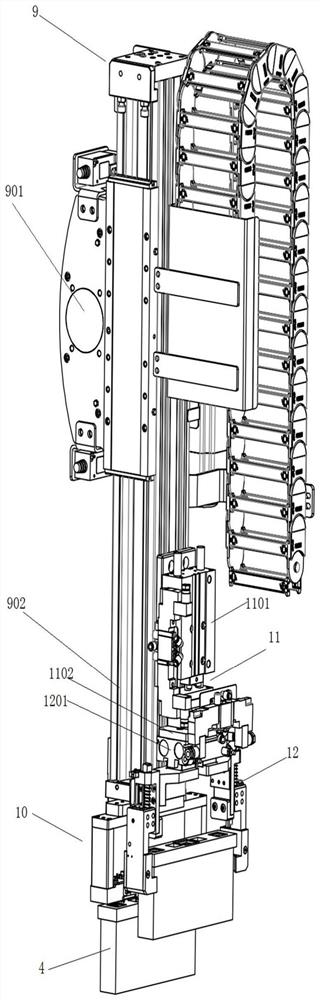

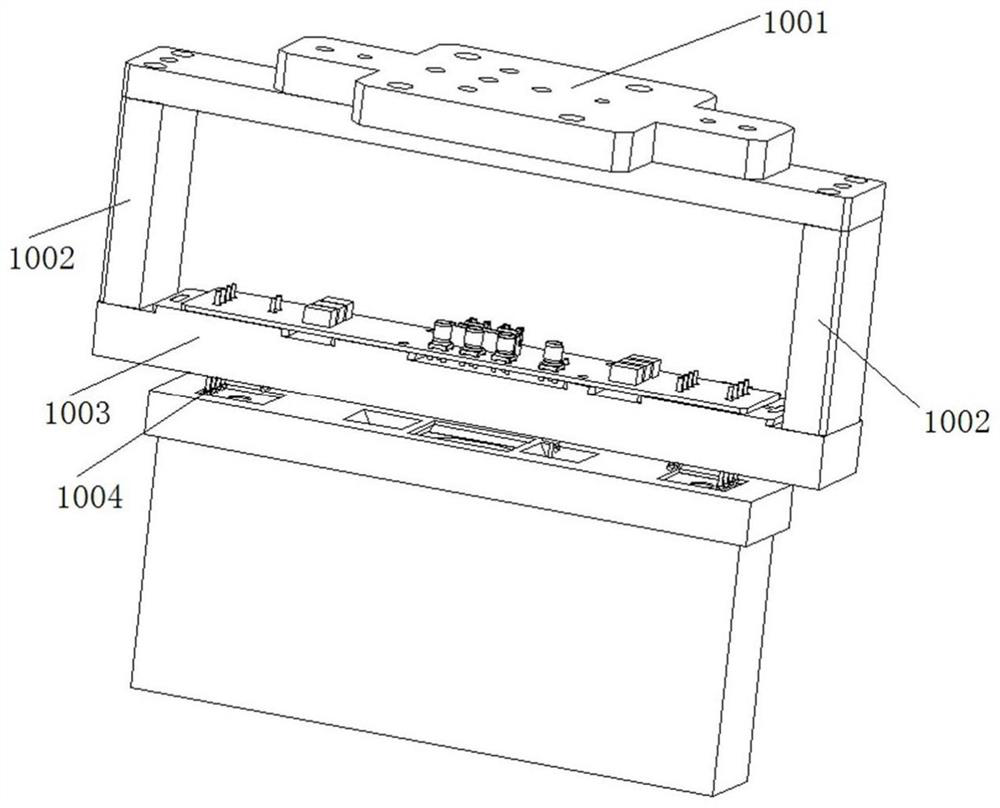

[0052] In order to realize the detection function, the battery 4 OCV detection equipment also includes: a detection unit 5 arranged inside the frame 1, and the detection unit 5 includes: an X-axis assembly 8, a Z-axis assembly 9, and an OCV detection a...

Embodiment 2

[0074] In the first embodiment above, the roller 606 used by the cable unit 6 realizes the conveying function. However, in the process of use, it was found that when the unqualified battery 4 was clamped to the drawstring unit 6 for loosening and unloading, it was difficult to ensure that the battery 4 would not shake (due to the lighter weight of the battery), that is, the battery 4 When being put down, the front end or the rear end of the battery 4 will be stuck in the adjacent roller 606 due to the instability when placed, and cannot be transported normally, resulting in congestion.

[0075] Therefore, the inventor has made further improvements to the drawstring unit 6 in order to solve the above problems: as Figure 6 to Figure 8 As shown, the drawstring unit 6 includes: a plurality of stands 601, a conveying plate that spans the stand 601 and is fixedly connected with the stand 601, and is mirror-symmetrically arranged on the conveying plate. The support plate 608, the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com