A double-sided incremental forming machine tool with large size and high rigidity

A progressive forming and high-rigidity technology, applied in the direction of feeding devices, storage devices, metal processing equipment, etc., can solve the problems of flexible deformation and the inability to adjust the size of the sheet material, etc., to achieve easy observation, strengthened support structure, and overall rigidity big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the accompanying drawings and examples. It should be understood that the following examples are intended to facilitate the understanding of the present invention, and have no limiting effect on it.

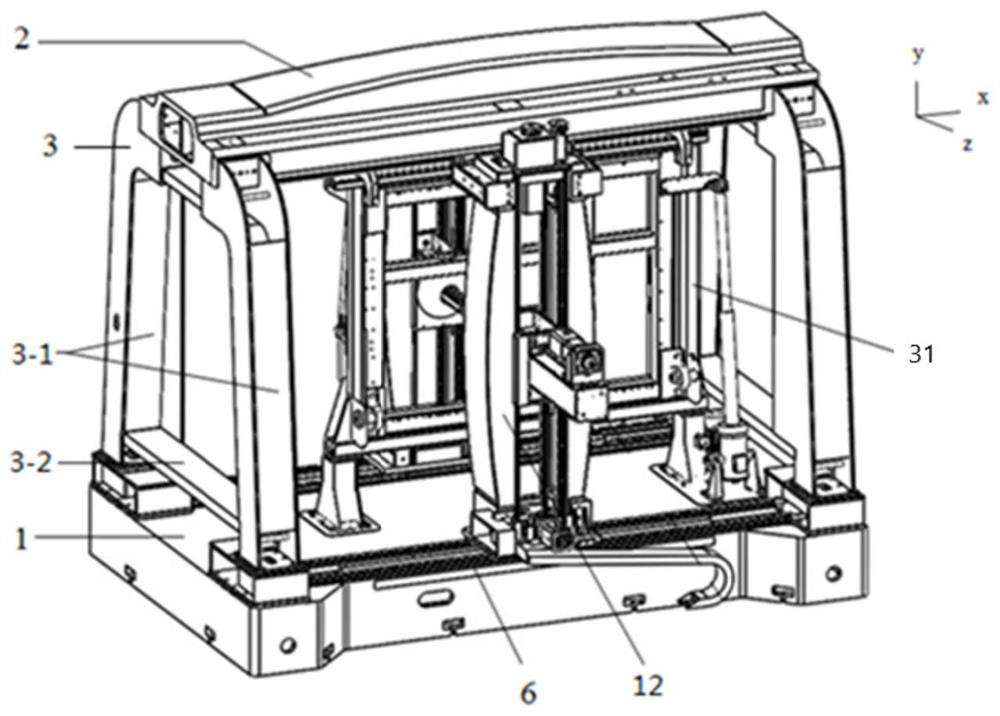

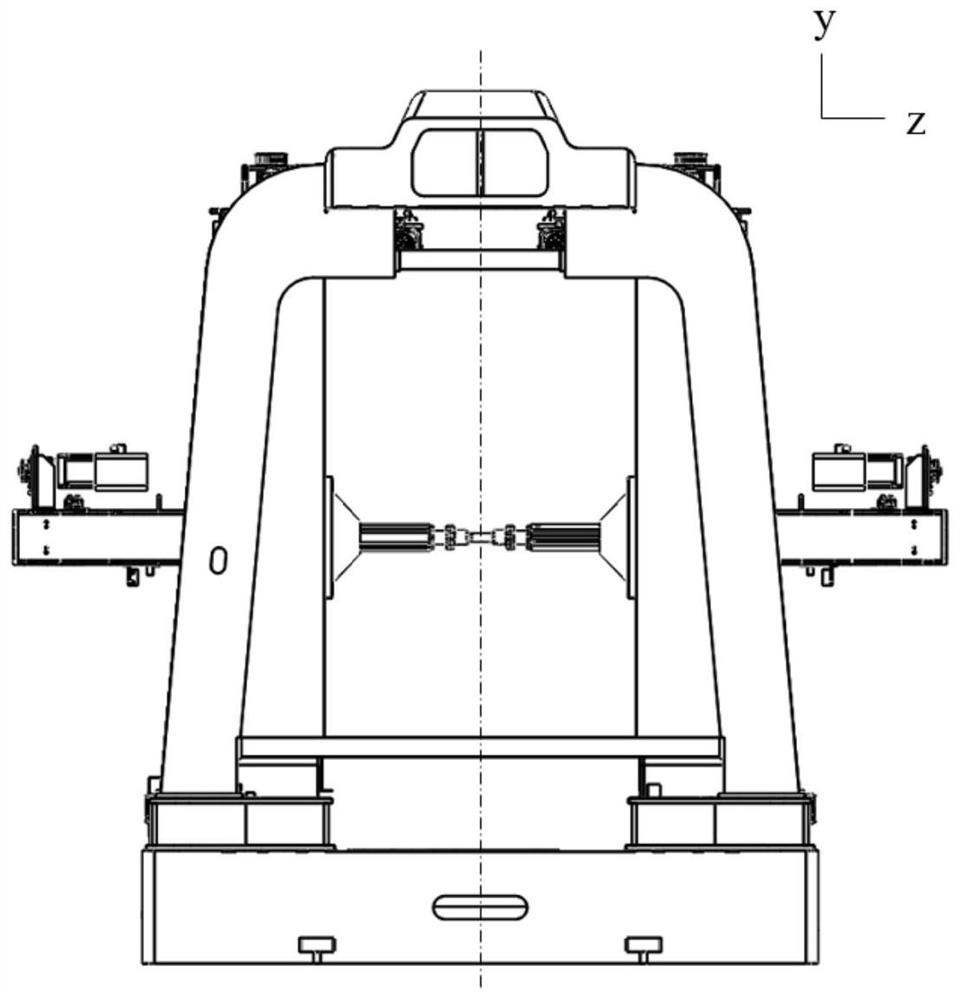

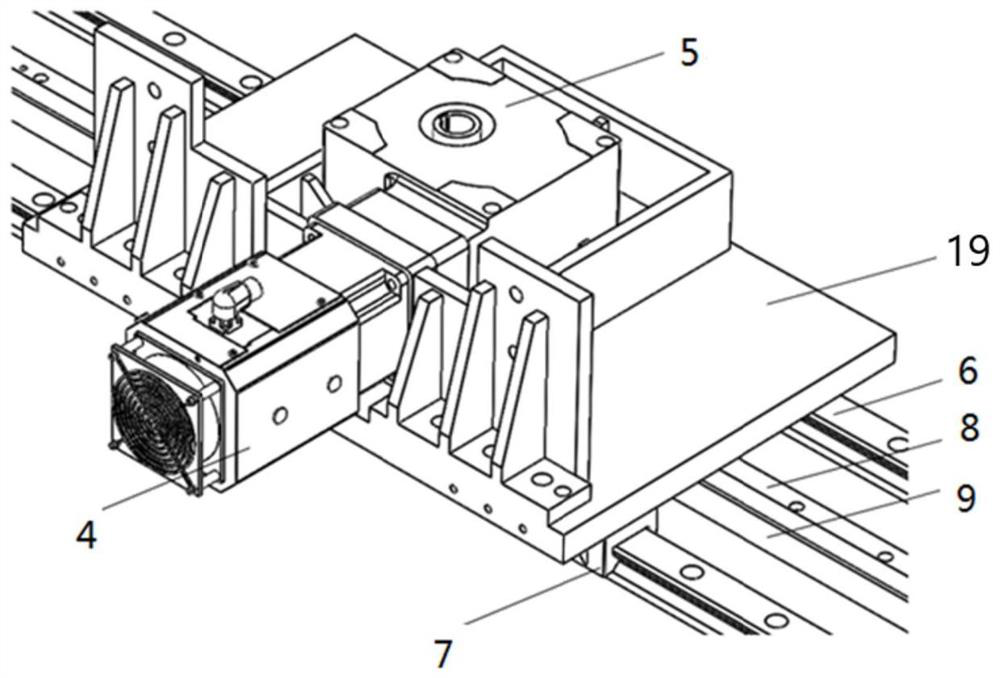

[0044] In this example, if figure 1 and 2 As shown, the present invention adopts a horizontal gantry mobile double-spindle structure, including a gantry frame, a motion system and a plate turning and clamping platform. Among them, the gantry includes a base 1, an upper beam 2, and two A-shaped columns 3 placed between them. For the convenience of description, the length direction of the base 1 is defined as the X direction, the width direction as the Z direction, and the height direction as the Y direction. In the X direction, two A-shaped columns 3 are respectively located at both ends of the base 1 along the X direction. Preferably, the upper beam 2 adopts a variable cross-section design, so that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com