Efficient lathe

A machine tool, high-efficiency technology, used in metal processing machinery parts, large fixed members, maintenance and safety accessories, etc., can solve the problems of low processing accuracy and efficiency, and achieve the effect of high processing accuracy, good rigidity and flexible design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

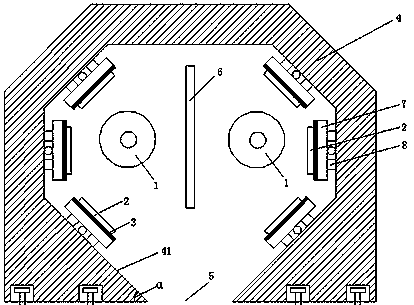

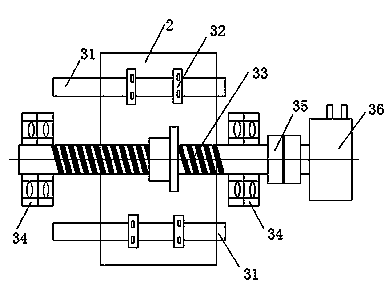

[0033] See figure 1 , a kind of high-efficiency machine tool of the present embodiment, comprises the spindle 1 that is arranged on the machine tool frame to clamp the workpiece and drive the workpiece to rotate, the workbench 2 for placing the tool, the workbench transmission mechanism 3 that provides the moving power for the workbench 2, Assembly frame 4, isolation board 6, carriage 7 and carriage transmission mechanism 8 that provides moving power for carriage 7.

[0034] There are two main shafts 1, which are arranged in parallel, and three worktables 2, three worktable transmission mechanisms 3, three carriages 7 and three carriage transmission mechanisms 8 are arranged around each main shaft 1, so that the main shaft 1 is surrounded trend. In order to reduce the vibration and mutual interference between the left and right spindles during cutting, the two spindles 1 can be placed on different bed bases; or the two spindles 1 can be set on the mineral casting base. A chu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com