Steel pipe and flange welding butt joint connection robot

A flange welding and robot technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., to meet the requirements of the degree of freedom, to facilitate welding and screwing, and to improve the degree of freedom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with specific embodiments. The exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not as a limitation to the present invention.

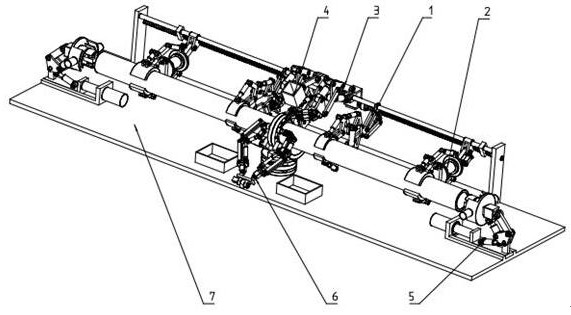

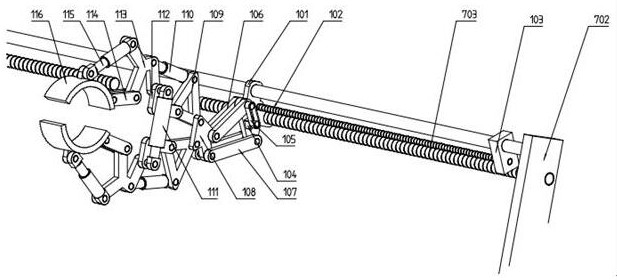

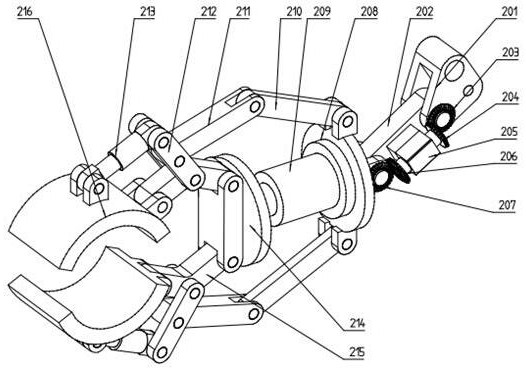

[0029] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 A steel pipe flange welding butt joint robot shown includes a main clamping part 1 , an auxiliary clamping part 2 , a welding part 3 , an auxiliary part 4 , a pipe transfer part 5 , a bolt screwing part 6 and a body part 7 .

[0030] The main frame foundation 101 and the transmission screw rod 703 of the main clamping part 1 adopt screw transmission, and are slidably installed with the transmission guide rail 704. A stepping motor is fixedly installed on the main frame foundation 101, and the clamping screw rod 102 is fixedly installed on the stepping motor. , the clamping small block 103 is slidably ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com