A steel pipe flange welding butt joint robot

A flange welding and robot technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., to achieve the effect of improving the degree of freedom, meeting the requirements of freedom, and convenient welding and screwing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the specific embodiments.

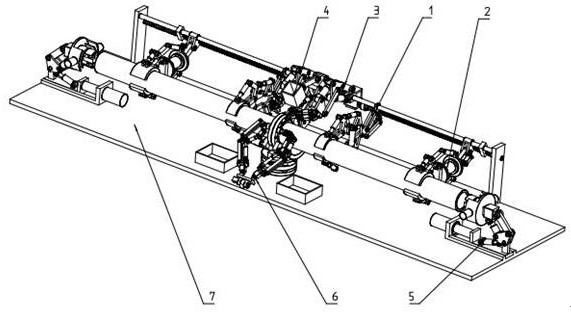

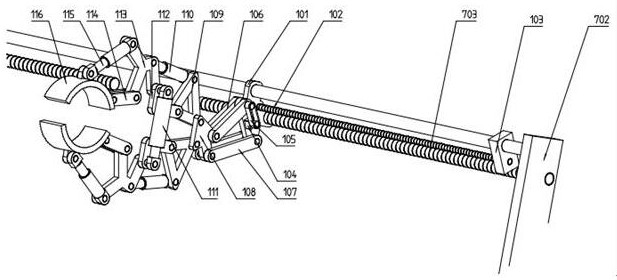

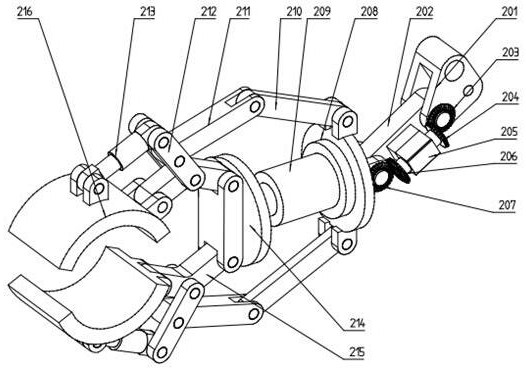

[0029] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 A steel pipe flange welding a docking robot, including the main clamping portion 1, the sub-clamping portion 2, the welding portion 3, the auxiliary portion 4, the transfer portion 5, the screw bolt portion 6, and the body portion 7.

[0030] The main frame base 101 of the main clamping portion 1 and the drive rod 703 use a threaded transmission, sliding with the drive guide rail 704, and fixedly mounted a stepping motor on the main frame base 101, and holds the screw 102 fixed to the stepping motor. The clamping small block 103 is slidable with the drive guide rail 704, and the other end of the clamping rod 102 is rotated and the clamping small piece 103 is mounted, and the first step feeder 104 is fixedly mounted on the main frame base 101, holding the main rod 106 and the main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com