Assembly type building sleeve grouting detection method

A technology of sleeve grouting and detection method, which is applied to measuring devices, processing response signals of detection, and analyzing solids by using sonic/ultrasonic/infrasonic waves, etc., can solve the difficulty of grouting quality control of grouting holes, insufficient expansion, and insufficient strength. and other problems, to achieve the effect of improving the level of detection technology, promoting application and promoting social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

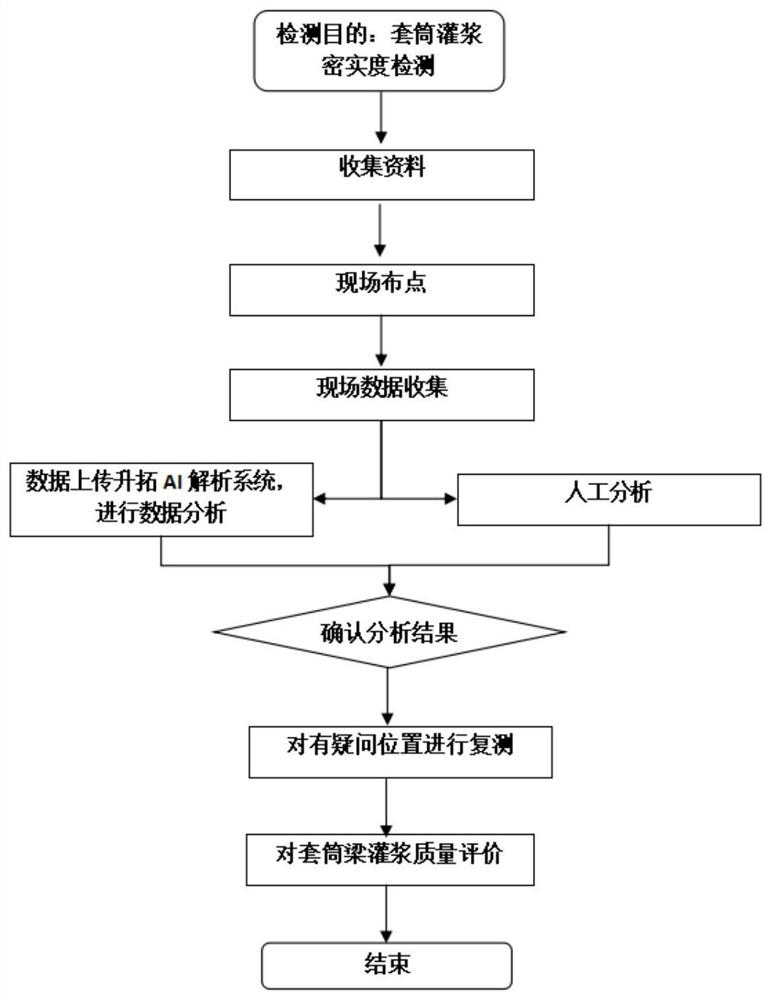

[0031] refer to Figure 1-4 , 1. The test method for sleeve grouting of prefabricated buildings, including the following steps:

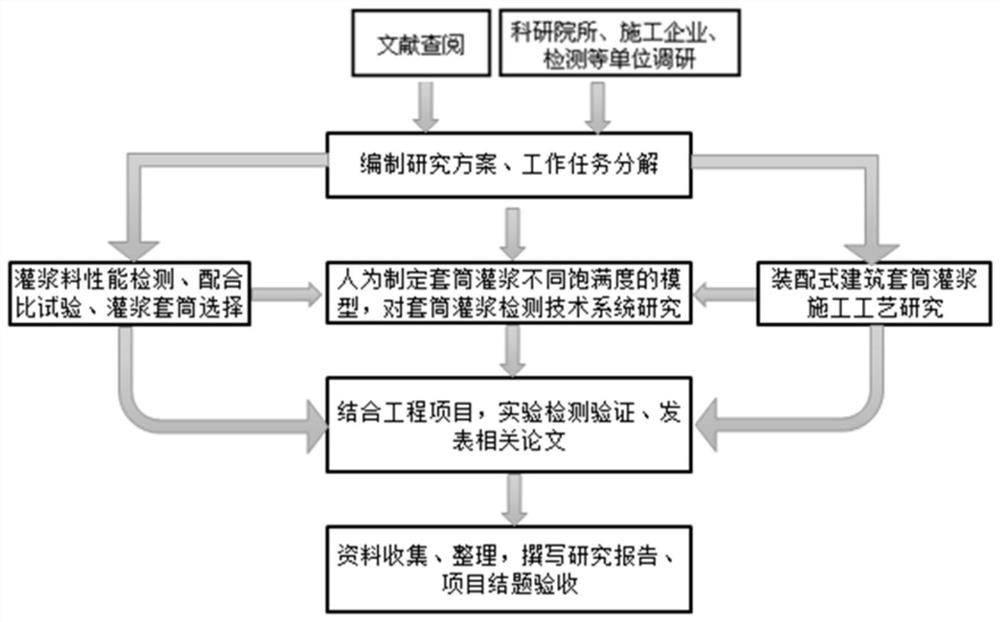

[0032] S1: Collection of data, performance testing of grouting material, mix ratio test, selection of grouting sleeve, test and detection of fluidity, mechanics and expansion of grouting material, selection of suitable grouting material type, grouting sleeve joint, and assembly type Research on the test method and principle of building sleeve grouting;

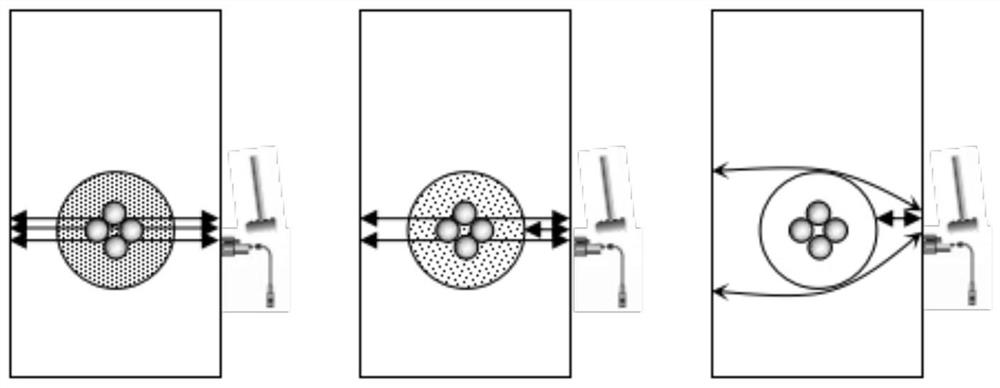

[0033] S2: On-site layout, artificially formulate models of different fullness for sleeve grouting of prefabricated buildings, conduct theoretical and practical, qualitative and quantitat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com