Orthopedic implant

An orthopedic implant and base-layer technology, applied in medical science, internal bone synthesis, external plate, etc., can solve the problems of poor biocompatibility, poor biocompatibility, low quality, etc., and improve postoperative recovery , the effect of promoting orthopedic regeneration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

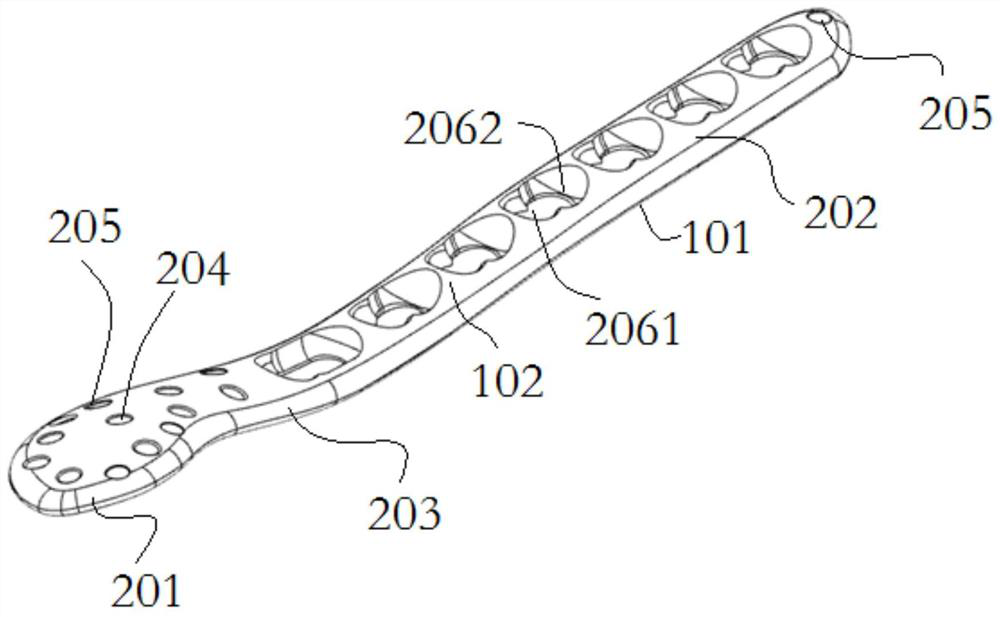

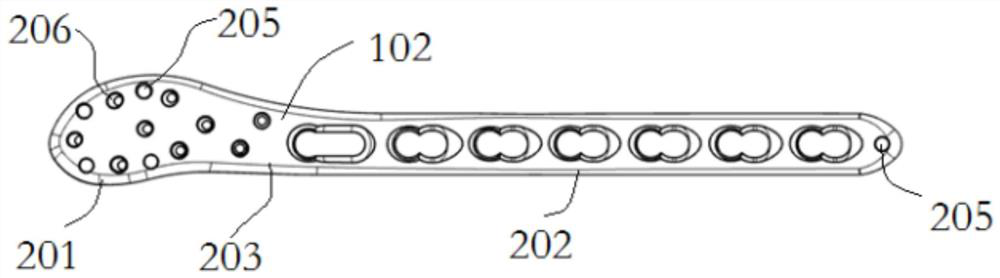

[0037] In some embodiments of the present invention, the first base layer is attached 101 on the second base layer 102 . Specifically, the magnesium alloy can be made into magnesium alloy thin paper, similar to tinfoil paper, cut into required size and shape, and attached to the surface of the second base layer 102 . The first base layer 101 does not necessarily cover the entire end surface of the second base layer 102 , the first base layer 101 can cover a part of the side end surface of the second base layer 102 as long as the contact area with the bone can be satisfied.

[0038] Only one layer of magnesium alloy structure needs to be constructed to achieve the effect of orthopedic implants promoting bone growth without designing the magnesium alloy layer to a thicker size, so the thickness of the first base layer 101 can be smaller than that of the second base layer 102 thickness.

Embodiment 2

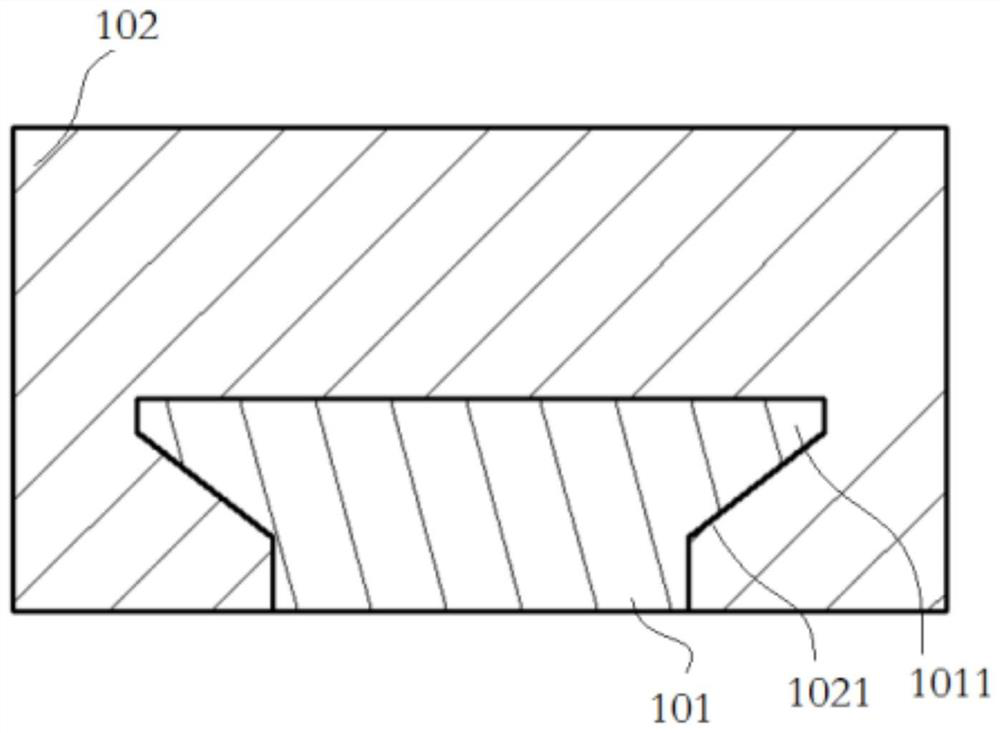

[0040] refer to figure 1 , in some embodiments of the present invention, the first base layer 101 is partially embedded in the second base layer 102 , or, the second base layer 102 is partially embedded in the first base layer 101 . That is, the first base layer 101 and the second integration 102 are configured as an embedded structure.

[0041] Specifically, if the first base layer 101 is partially embedded in the second base layer 102, the width of the first base layer 101 embedded in the second base layer 102 is greater than the width of the first base layer 101 outside the second base layer 102;

[0042] If the second base layer 102 is partially embedded in the first base layer 101 , the width of the second base layer 102 embedded in the first base layer 101 is greater than the width of the second base layer 102 outside the first base layer 101 .

[0043] In some embodiments of the present invention, the first base layer 101 and the second base layer 102 are provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com