Multi-powder storage metering equipment

A technology of measuring equipment and powder, which is applied in the direction of weighing equipment, weighing, and measuring devices for materials with special properties/forms, and can solve problems such as the difficulty of adding other types of powder and expanding the storage capacity of mineral powder. Reach the effect of reducing equipment cost and reducing dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific embodiments of the present invention will be described below with reference to the drawings.

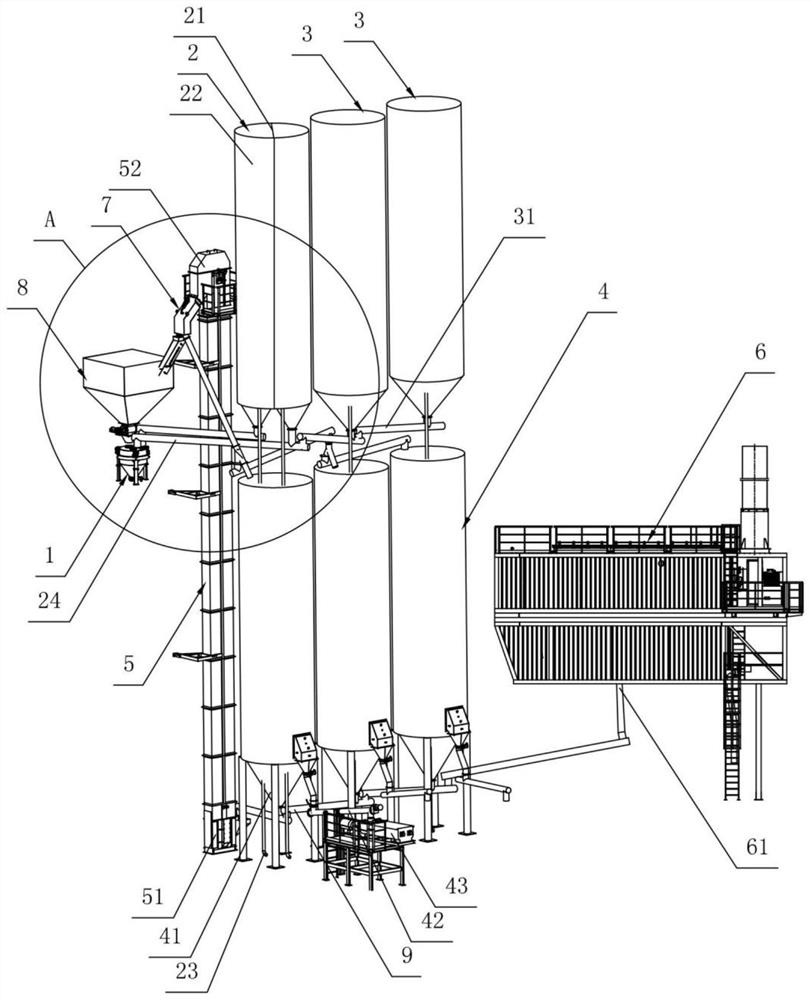

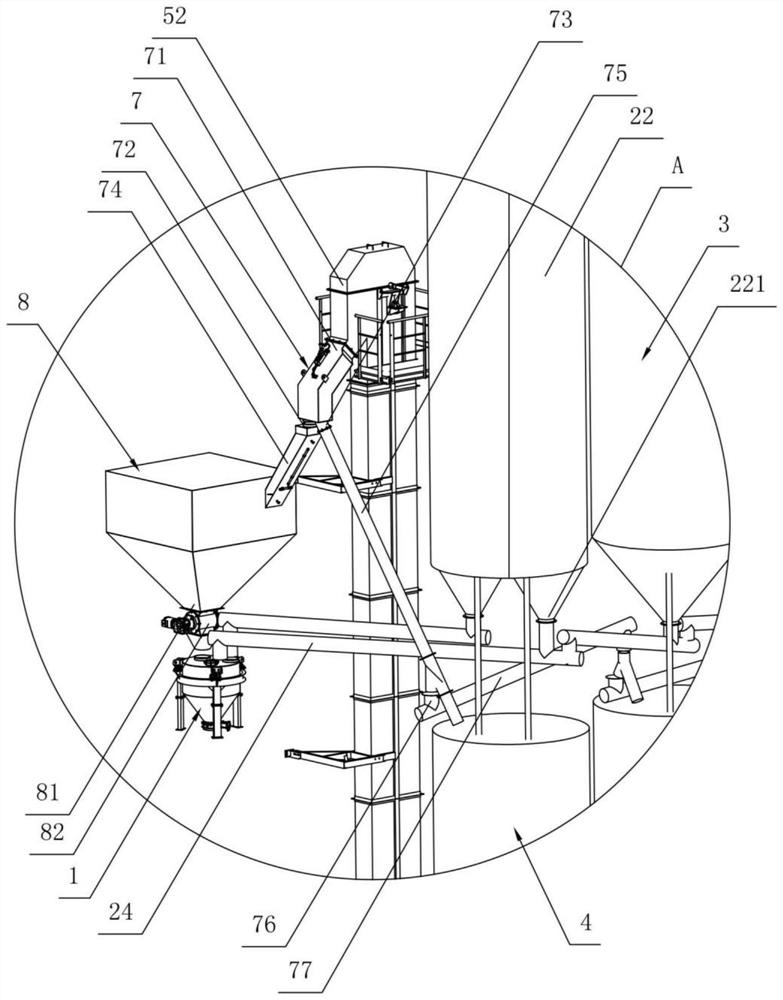

[0026] Refer to figure 1 , figure 2 . A multi-powder material storage and measurement equipment, including

[0027] Measurement scale 1;

[0028] The monomer twin powder tank 2 is provided with a partition 21 to divide the interior into two silos 22. The two silos 22 are used to hold different powders, and are connected to the corresponding powders. The material is driven into the powder pipe 23 in the silo 22, and the lower discharge ends 221 of the two silos 22 are respectively connected to the weighing scale 1 through the main metering screw 24; the main metering screw 24 can be connected to the zero through the auxiliary metering screw 31 One, one or more powder loading tanks 3; in this embodiment, the number of powder loading tanks 3 is two;

[0029] The recovery powder tank 4 is used to store recovered powder. Each monomer twin powder tank 2 and the upper powder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com