A magnet production material collection device and method of use

A collection device and magnet technology, applied in the directions of transportation and packaging, loading/unloading, conveyor objects, etc., can solve the problems of low collection efficiency and high cost consumption of manipulators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Next, the technical solutions in the embodiments of the present invention will be apparent from the embodiment of the present invention, and it is clearly described, and it is understood that the described embodiments are merely embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, there are all other embodiments obtained without making creative labor without making creative labor premises.

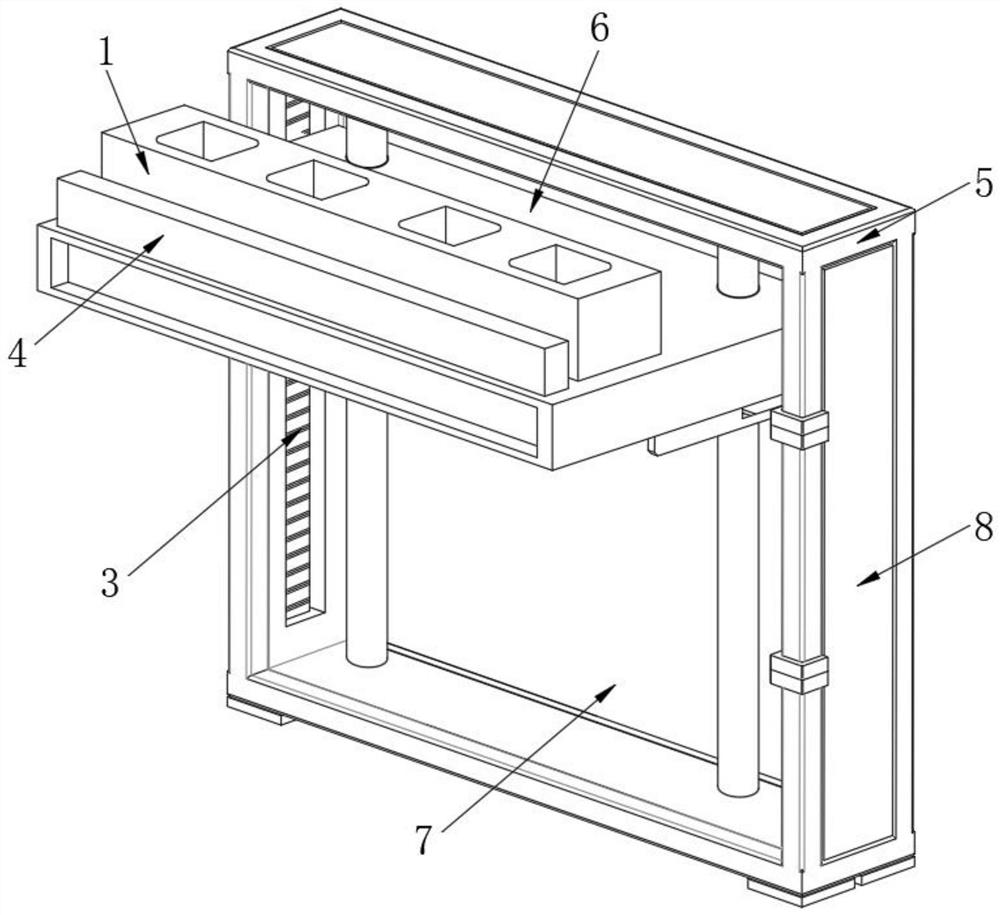

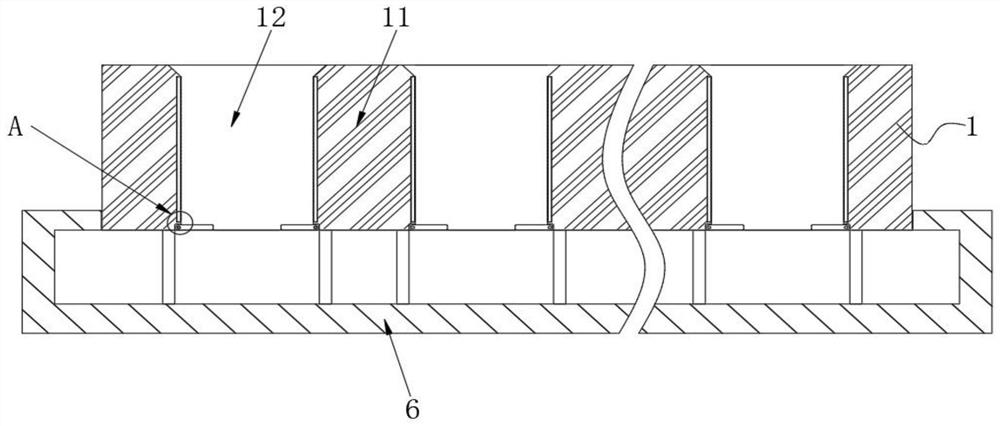

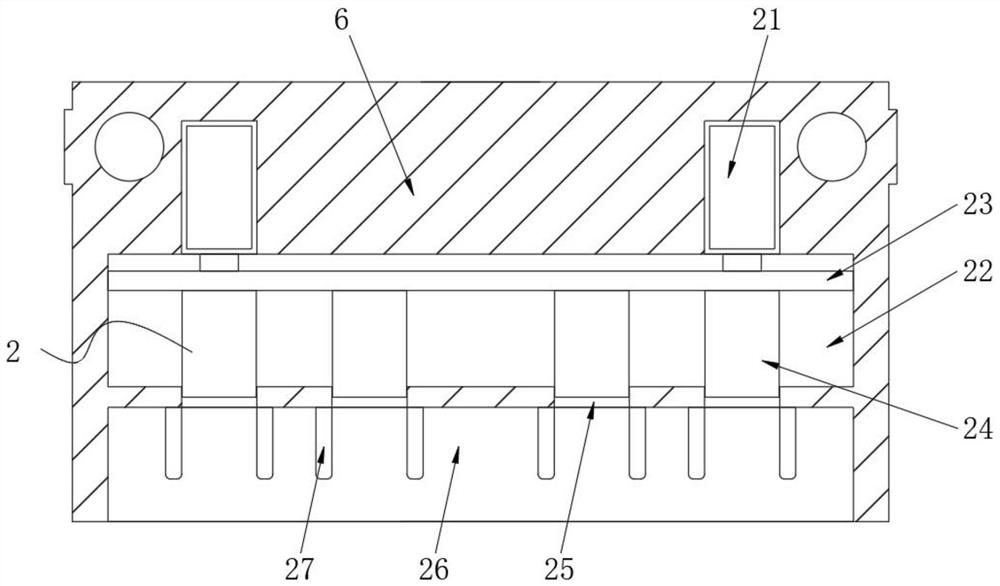

[0039] See Figure 1-7 The present invention provides a technical solution: A magnet material produced under the collecting means comprises a frame 5 and a collection box located inside the frame 5, 6, 5 of the internal housing defines a chamber 7 activity, and collected in the active frame 6 up and down inside the chamber 7, both sides of the chassis 5 is fixedly connected with a mounting plate 8, and two opposite side of the mounting plate 8 is provided with a displacement mechanism 3, the opposite side of two 3 respective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com