Adaptable sliding type textile pay-off device

A pay-off device and sliding technology, applied in the field of textile production, can solve problems such as inability to use a variety of pay-off work, unsatisfactory guiding and guiding effects, sliding and adjustment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

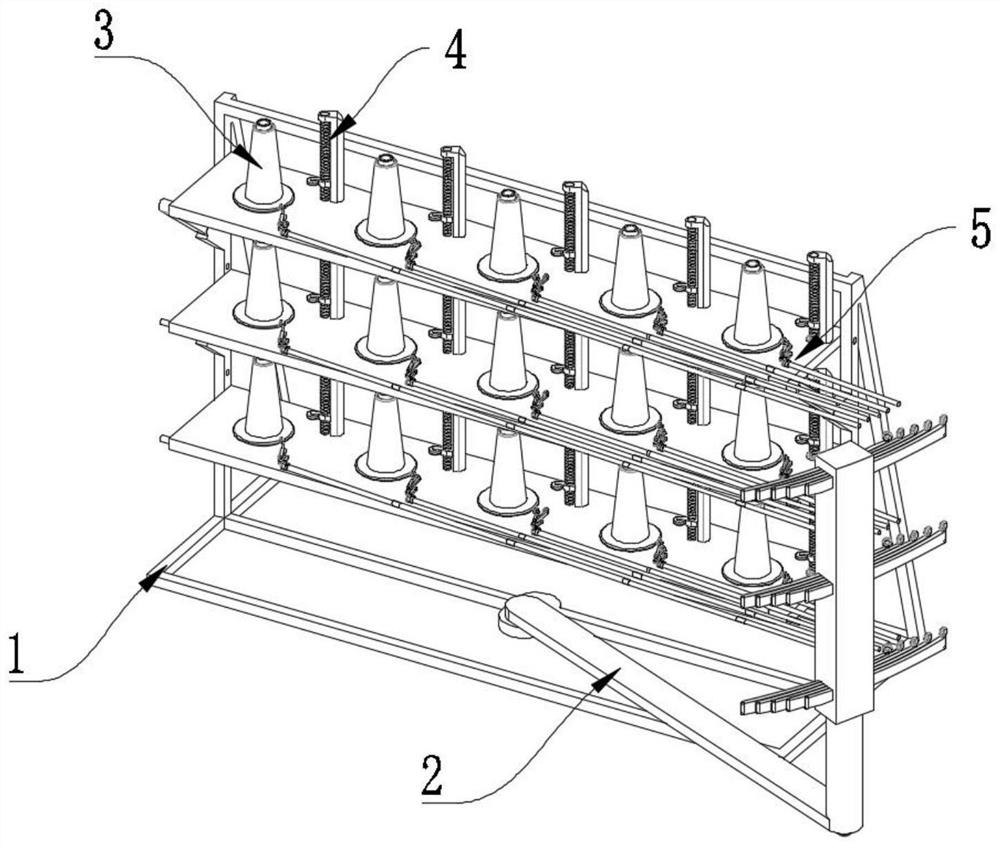

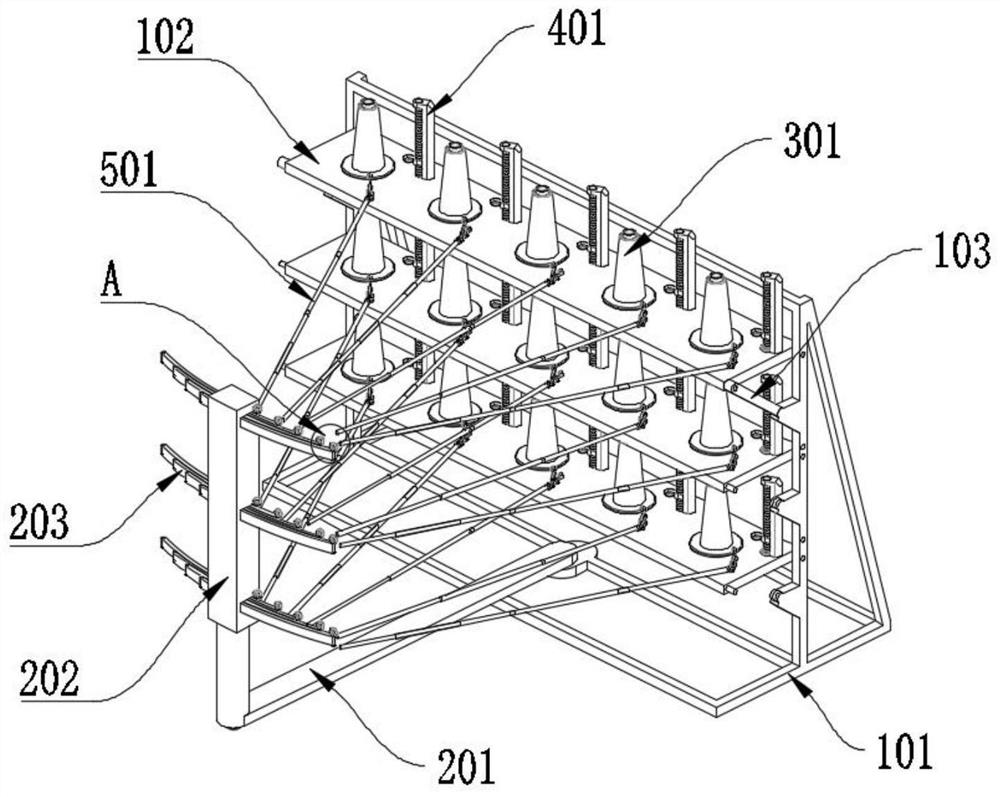

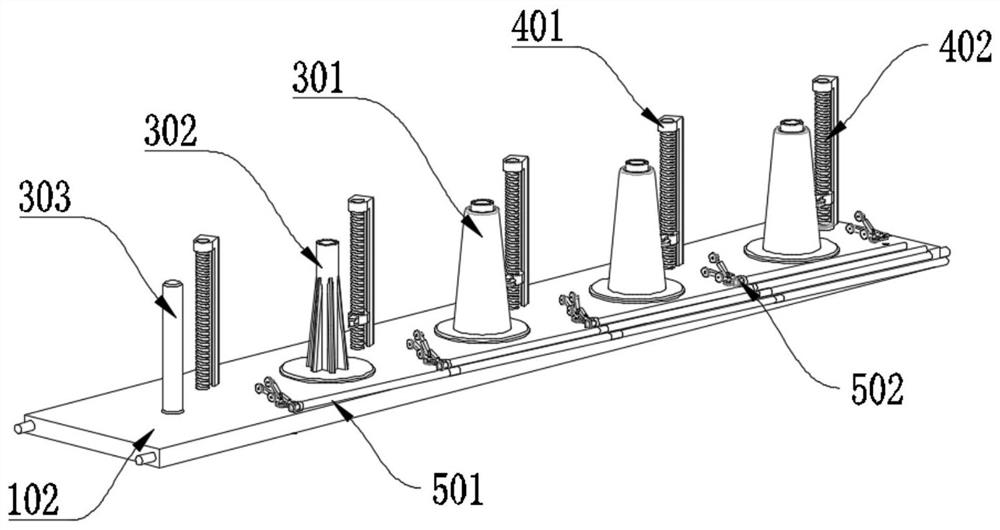

[0035] as attached figure 1 to attach Figure 9 Shown:

[0036]The present invention provides a slidable textile pay-off device with strong adaptability, which includes a frame structure 1; a swing structure 2 is hingedly installed at the middle position of the bottom of the frame structure 1, and an installation structure 3 is arranged on the frame structure 1; The right side of the structure 3 is provided with a sliding structure 4 near the rear end, and a guiding structure 5 is installed at the front end of the sliding structure 4; the sliding structure 4 includes a positioning plate 401, a screw rod 402, a sliding block 403, and a guide wheel 404 , the buffer pad 405, the positioning plate 401 of the sliding structure 4 is installed on the right side of the pay-off wheel 301, and the positioning plate 401 is rotated towards the side of the pay-off wheel 301. A screw 402 is installed, and the screw 402 is sleeved Sliding block 403 is installed, and sliding block 403 is ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com