Table frame convenient to assemble

A technology that facilitates assembly and table stand. It is applied to the legs of general furniture, tables that can change the height of the table, tables, etc. It can solve the problems of troublesome installation, unfriendly users, and the lifting platform is not assembled properly, and achieves low precision requirements. Manufacturing cost controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

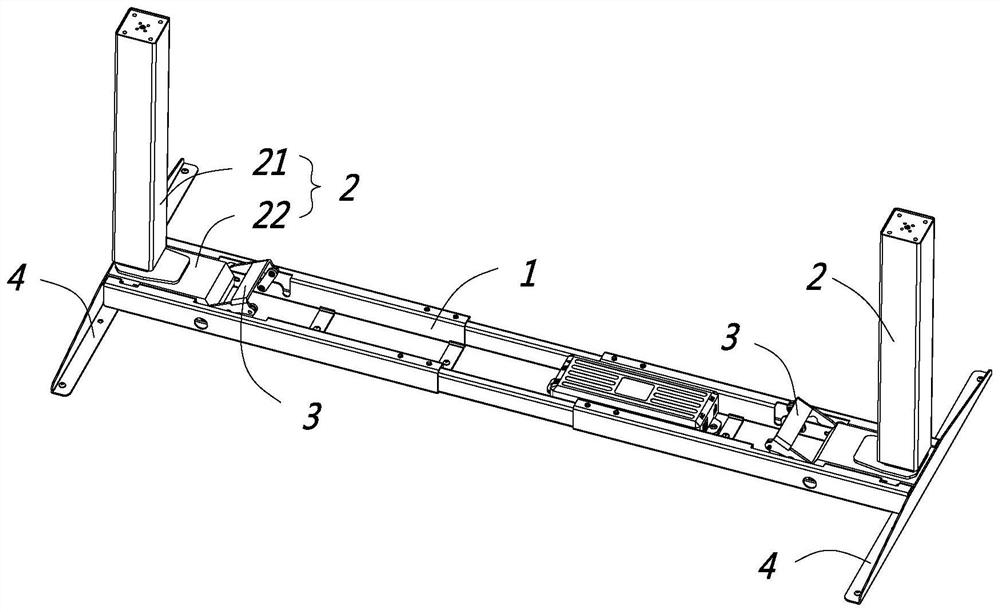

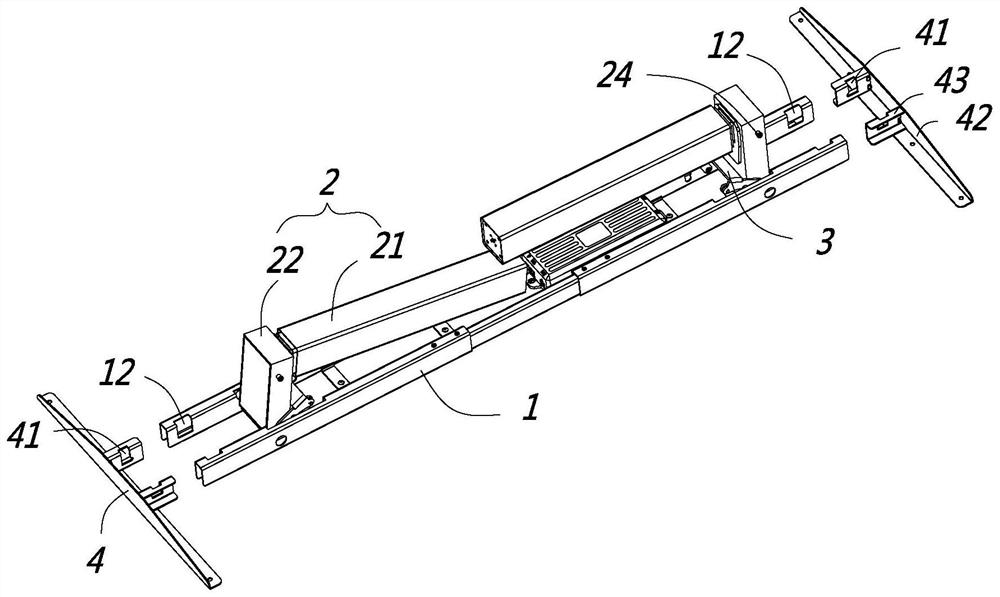

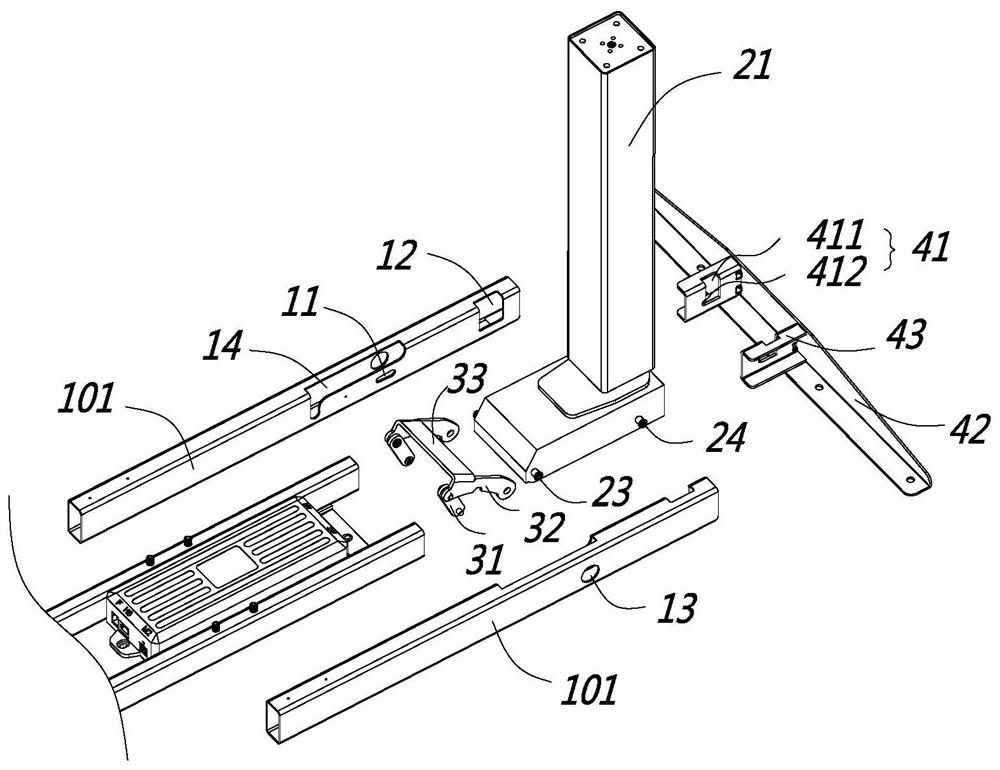

[0030] Such as Figure 1 to Figure 5 As shown, the present embodiment is a table frame for easy assembly, including a crossbeam 1. For the convenience of the following description, the length direction of the crossbeam 1 is defined as the transverse direction, and the width direction of the crossbeam 1 is defined as the longitudinal direction. There is a lifting column 2, the table frame also includes a side plate 4 detachably connected to the end of the beam 1, the lifting column 2 includes a top shell 22 and a column part 21, the lifting column 2 in this embodiment is preferably It is an electric lifting column, and a transmission assembly is arranged in the column part 21. The transmission assembly is driven by a driving motor, and the driving motor is arranged in the top housing 22. Since the internal structure of the electric lifting column is widely disclosed in the prior art, this article I won't go into too much detail. In this embodiment, the top case 22 includes a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com