A kind of automobile electronic gear shifter, control method and controller

A technology of automotive electronics and control methods, applied in the direction of transmission control, components with teeth, belts/chains/gears, etc., can solve problems such as failure to shift gears, inability to judge gears, etc., and reduce the probability of prompting failures , Improve the effect of fault redundancy rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

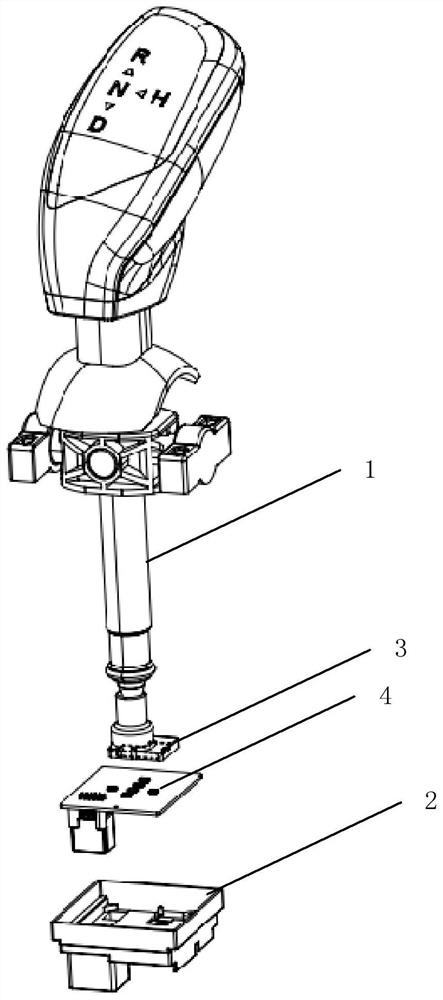

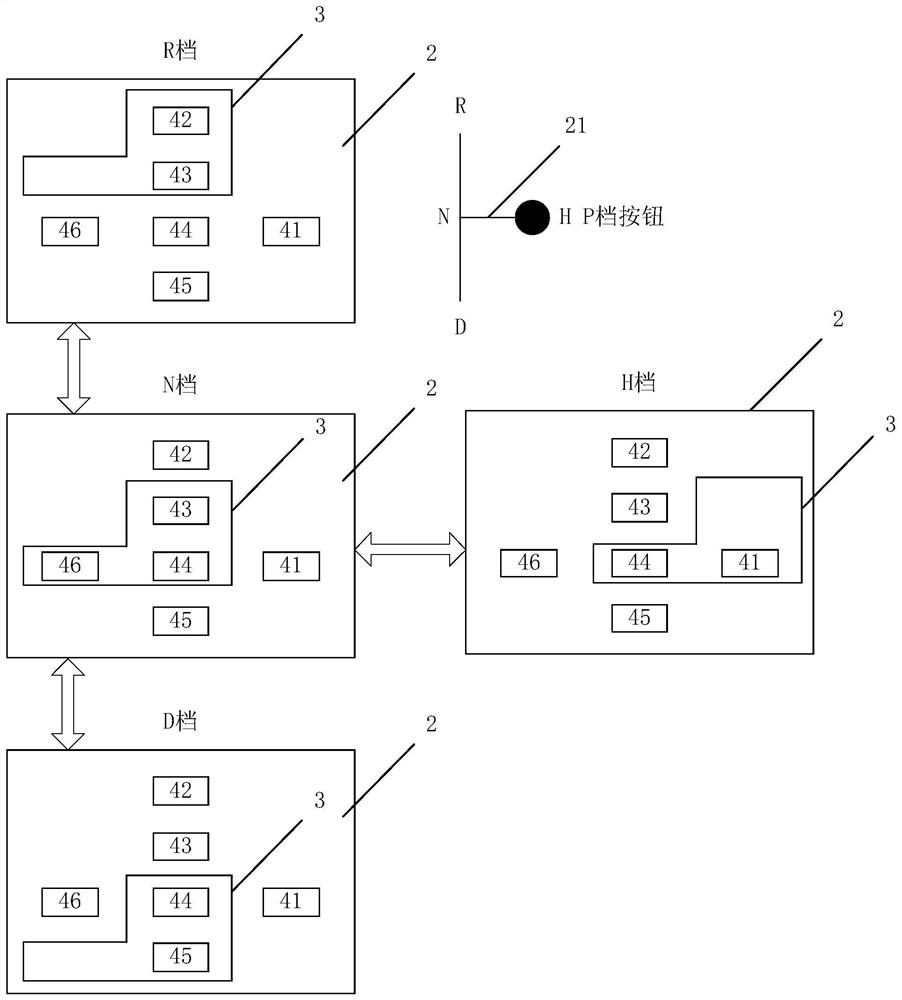

[0070] like figure 1 Shown is a schematic structural diagram of an automotive electronic shifter according to an embodiment of the present invention, including: a shift lever 1, a shift base 2, and a controller, the shift base 2 is provided with a plurality of shift positions, The shift lever 1 moves on the shift base 2 and can switch between a plurality of the shift positions;

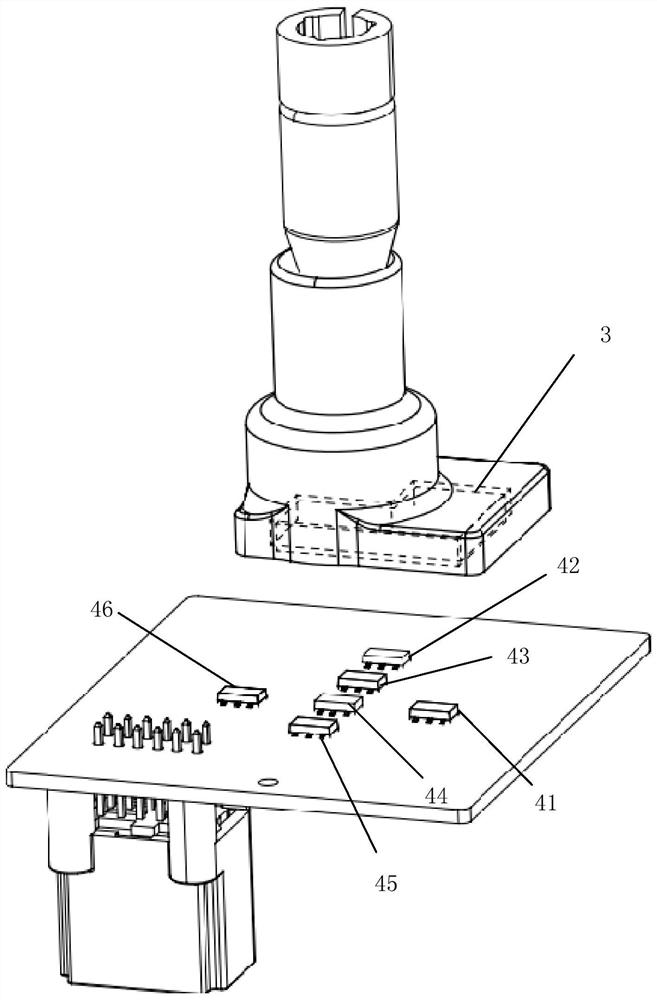

[0071] The shift lever 1 is provided with a first detection element 3, the shift base 2 is provided with a plurality of second detection elements 4, or the shift lever 1 is provided with a plurality of second detection elements 4, The shift base 2 is provided with a first detection element 3;

[0072] The second detection element 4 outputs an output signal including an in-position signal or a reset signal according to the relative positional relationship with the first detection element 3;

[0073] When the shift lever 1 is switched from one of the shift positions to another of the shift positions, ...

Embodiment 2

[0088] like Figure 1 to Figure 5 As shown, a second embodiment of the present invention is an automotive electronic shifter, comprising: a shift lever 1, a shift base 2, and a controller, the shift base 2 is provided with a plurality of shift positions, the The shift lever 1 moves on the shift base 2 and can switch between a plurality of the shift positions;

[0089] The shift lever 1 is provided with a first detection element 3, the shift base 2 is provided with a plurality of second detection elements 4, or the shift lever 1 is provided with a plurality of second detection elements 4, The shift base 2 is provided with a first detection element 3;

[0090] The second detection element 4 outputs an output signal including an in-position signal or a reset signal according to the relative positional relationship with the first detection element 3. When the first detection element 3 covers the second detection element 4, the The second detection element 4 outputs an in-positio...

Embodiment 3

[0183] like Image 6 Shown is a working flow chart of a control method of the aforementioned automobile electronic shifter of the present invention, including:

[0184] Step S601, obtain the output signals of all the second detection elements 4, and generate an output signal group including the output signals of each of the second detection elements 4;

[0185] Step S602, acquiring the gear to be selected corresponding to the output signal group;

[0186] Step S603, switching the shift gear of the vehicle to the gear to be selected.

[0187] Specifically, this embodiment is mainly applied to a controller of an automotive electronic gear shifter. The controller executes step S601 to acquire the output signals of all the second detection elements 4 , and generates an output signal including each of the second detection elements 4 The output signal group of the output signal. The output signal group includes the output signal of each second detection element 4 . by image 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com