Inspection method for production of insulating paint for enameled wires

An inspection method and insulating varnish technology, applied in the direction of mechanical devices, measuring devices, instruments, etc., can solve the problem of low test accuracy and achieve the effect of accurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

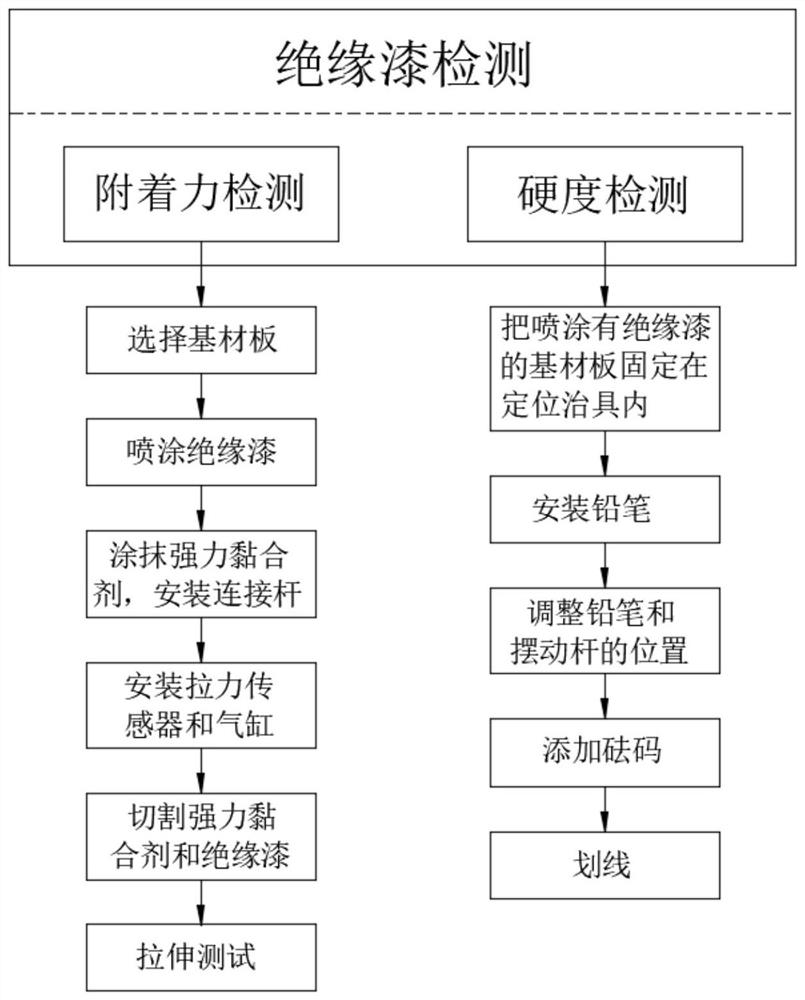

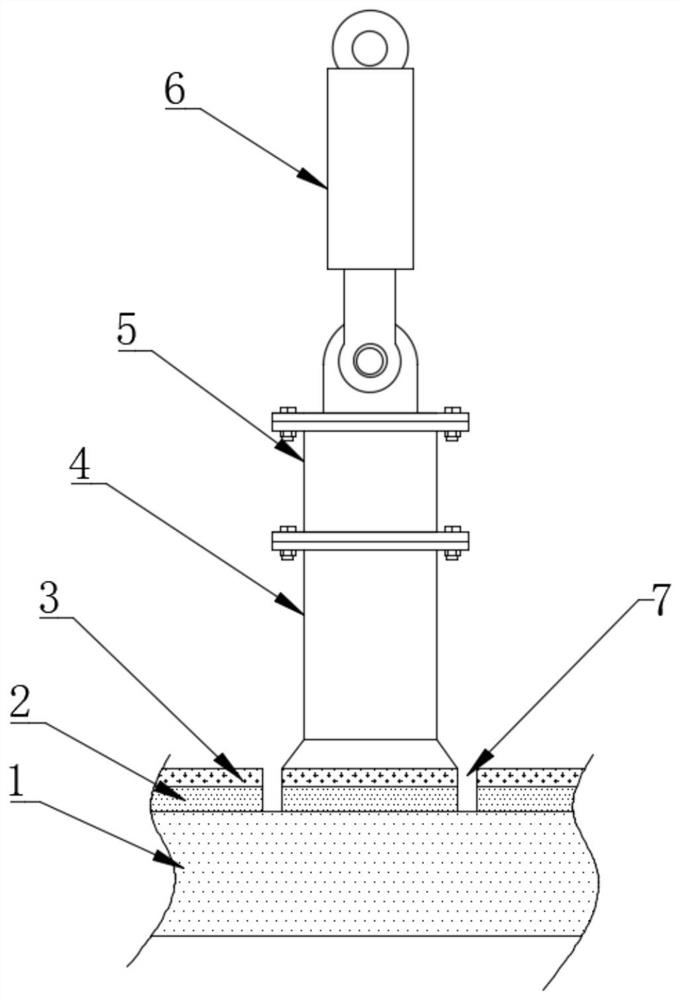

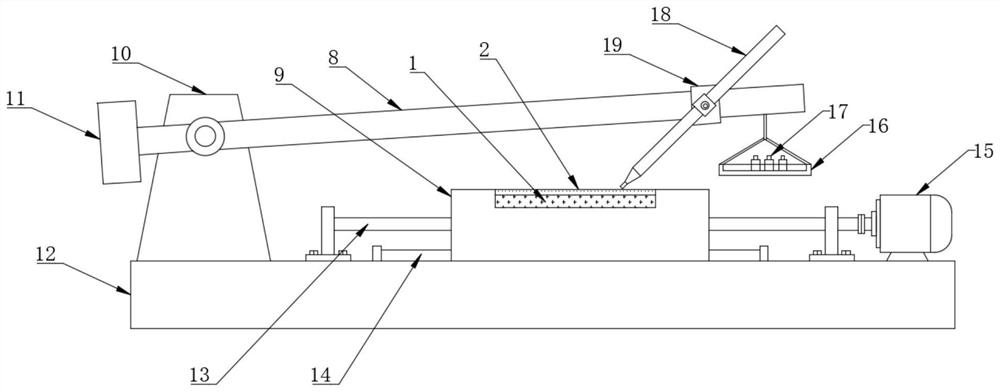

[0029] see figure 1 and figure 2 , in the embodiment of the present invention, a kind of inspection method for the production of insulating varnish for enameled wire, comprises adhesion detection method and hardness detection method, and adhesion detection method comprises the following steps:

[0030] S1. Select the substrate board 1 with the same enameled wire material, and make the substrate board 1 fixed;

[0031] S2. According to the production process of the enameled wire, evenly spray the insulating varnish 2 on the base plate 1, and perform drying treatment;

[0032] S3. Spread the strong adhesive 3 evenly on the insulating paint 2. Before the initial setting of the strong adhesive 3, press the bottom end of the connecting rod 4 to the strong adhesive 3. Through the strong adhesive 3, connect the connecting rod 4 with the strong adhesive 3. The insulating paint 2 is firmly bonded together, and the strong adhesive 3 can be epoxy resin adhesive or quick-drying cyanoac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com