Voltage adjustment method of load sensor

A technology of load sensor and voltage adjustment, which is used in the measurement of the properties of piezoelectric devices, instruments, parts of grinding machine tools, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

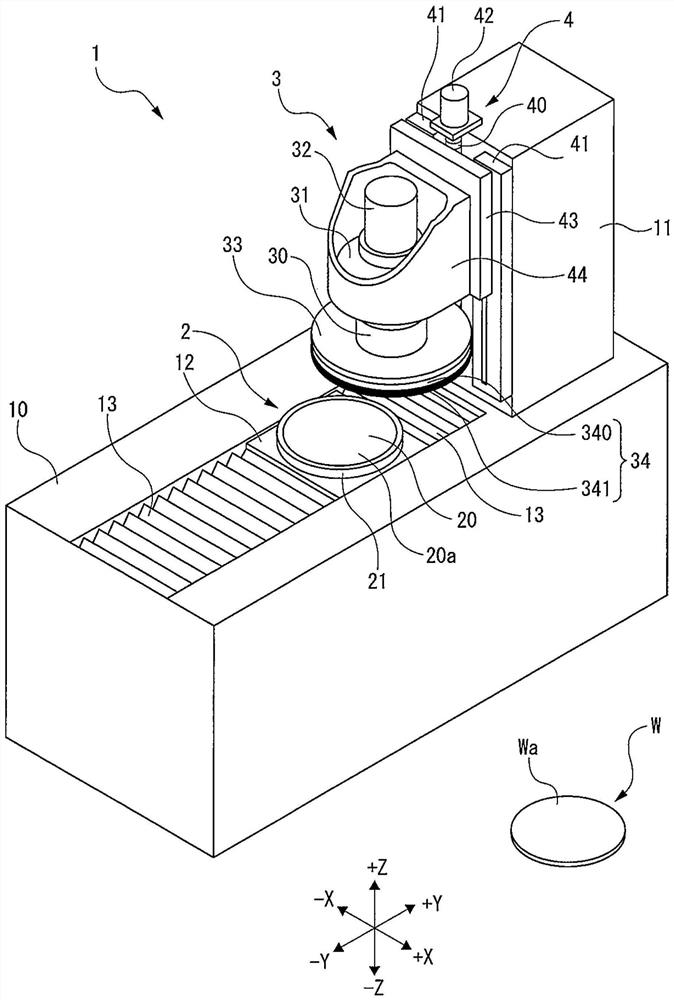

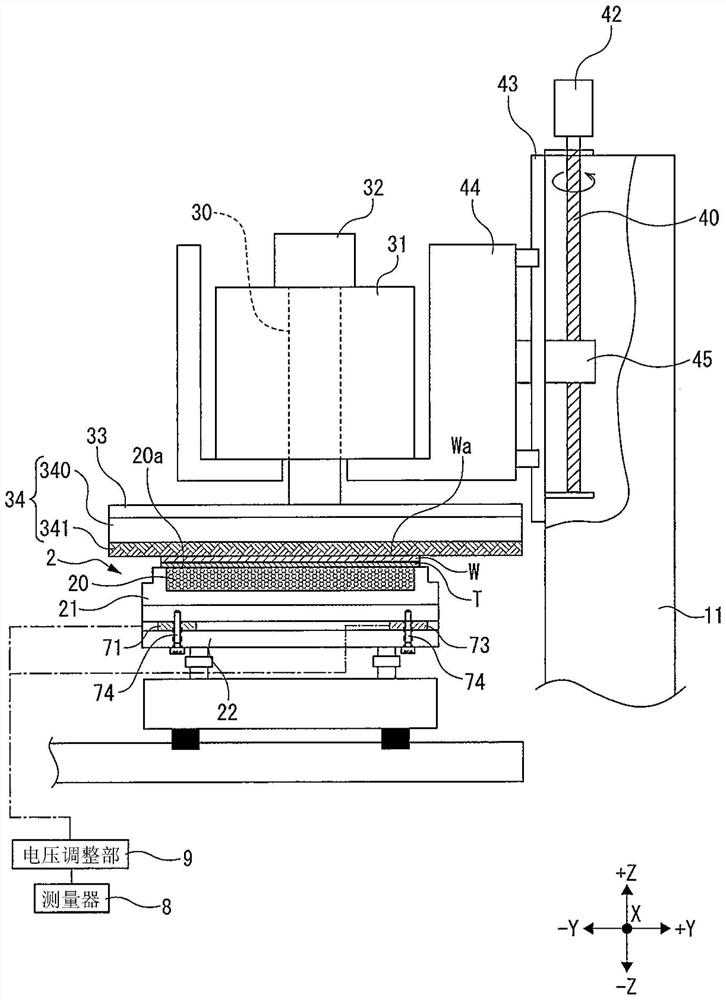

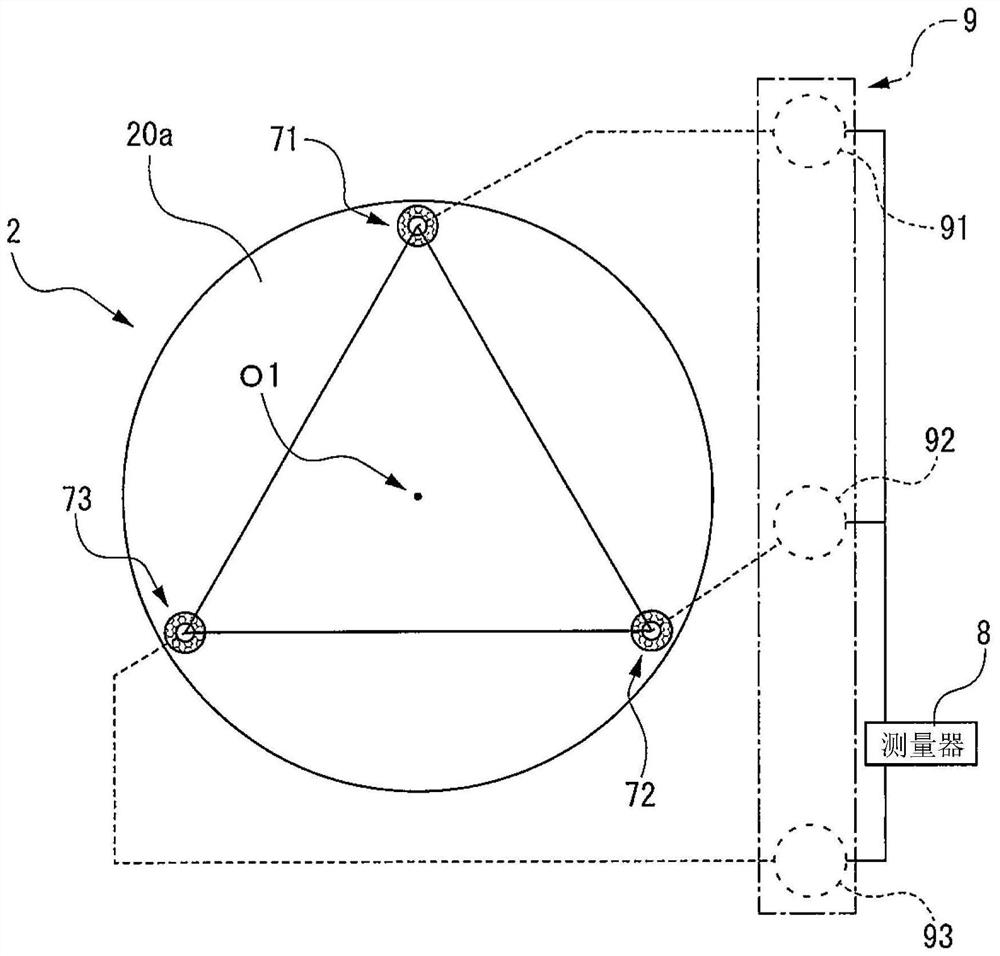

[0023] 1 About the grinding device

[0024] figure 1 The illustrated polishing apparatus 1 is a polishing apparatus for polishing the wafer W held by the chuck table 2 by bringing the polishing member 341 into contact with it. Hereinafter, the polishing device 1 will be described.

[0025] like figure 1 As shown, the grinding device 1 has: a base 10 extending along the Y-axis direction; and a column 11 erected on the +Y direction side of the base 10 .

[0026] A chuck table 2 is provided on a base 10 of the grinding device 1 . The chuck table 2 is a disc-shaped table that holds the wafer W, and includes a suction unit 20 having a holding surface 20 a and a frame 21 that supports the suction unit 20 . With the wafer W placed on the holding surface 20a, suction force exerted by a suction source (not shown) is transmitted to the holding surface 20a, whereby the wafer W is sucked and held by the holding surface 20a.

[0027] A cover 12 is disposed around the chuck table 2 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com