Nozzle arrangement and method for processing a material for processing with a processing medium

A nozzle device and nozzle technology, which are applied in the direction of liquid processing of printed circuits, devices for coating liquid on surfaces, electrical components, etc., can solve the problems of processing workstation loss, material loss to be processed, processing system blockage, etc., and achieve consumption and cost. Low, save processing steps, shorten the effect of processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

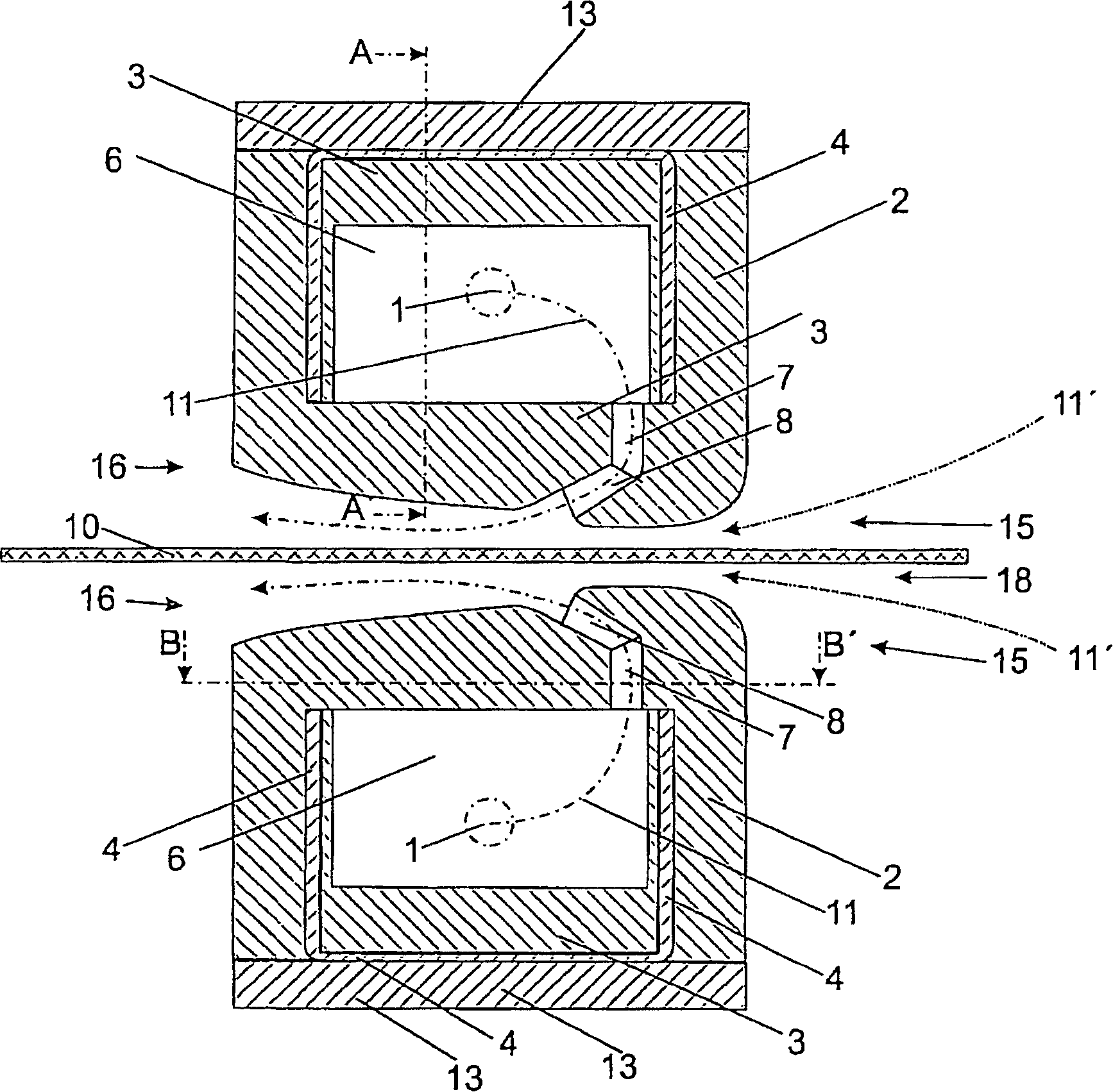

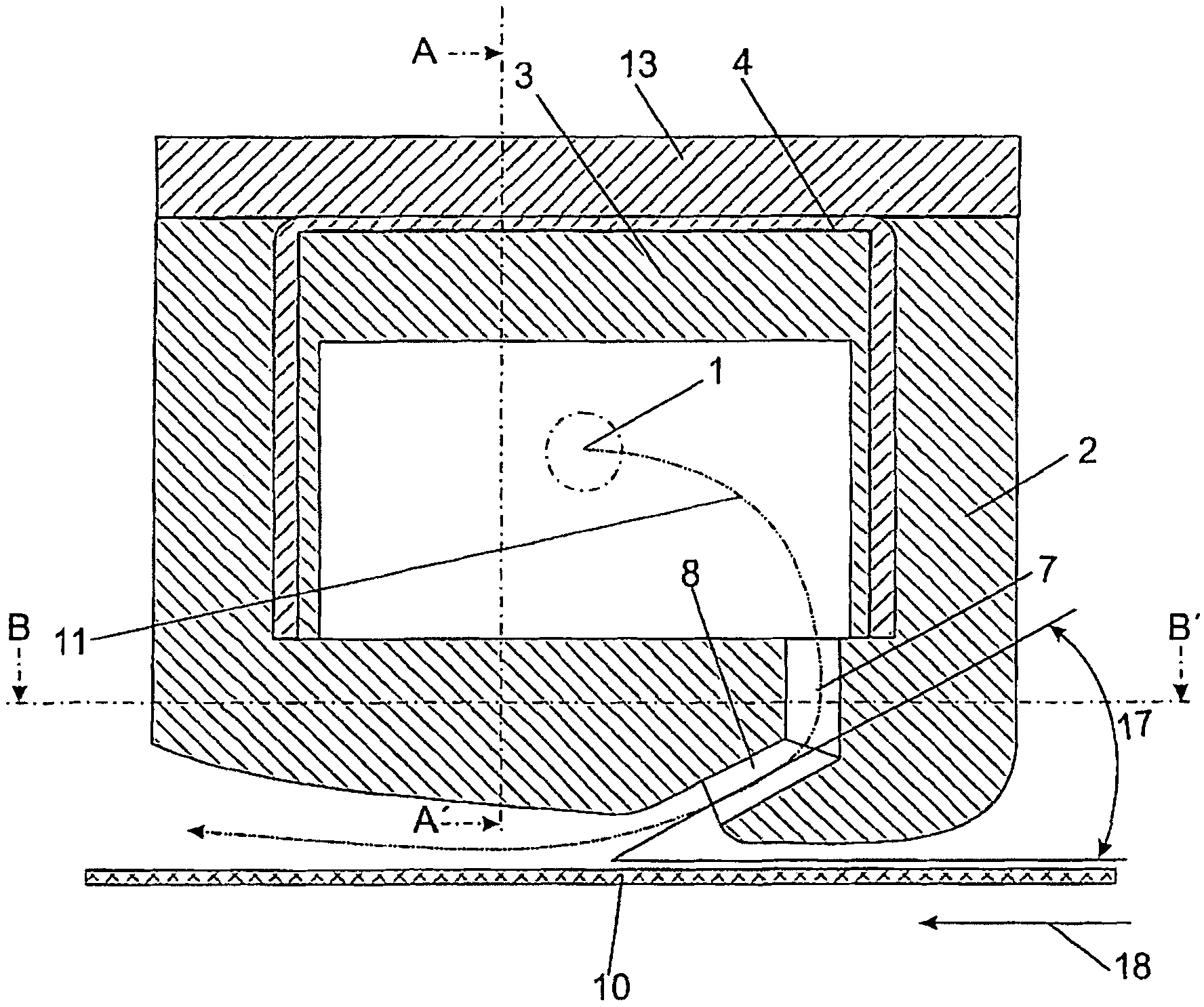

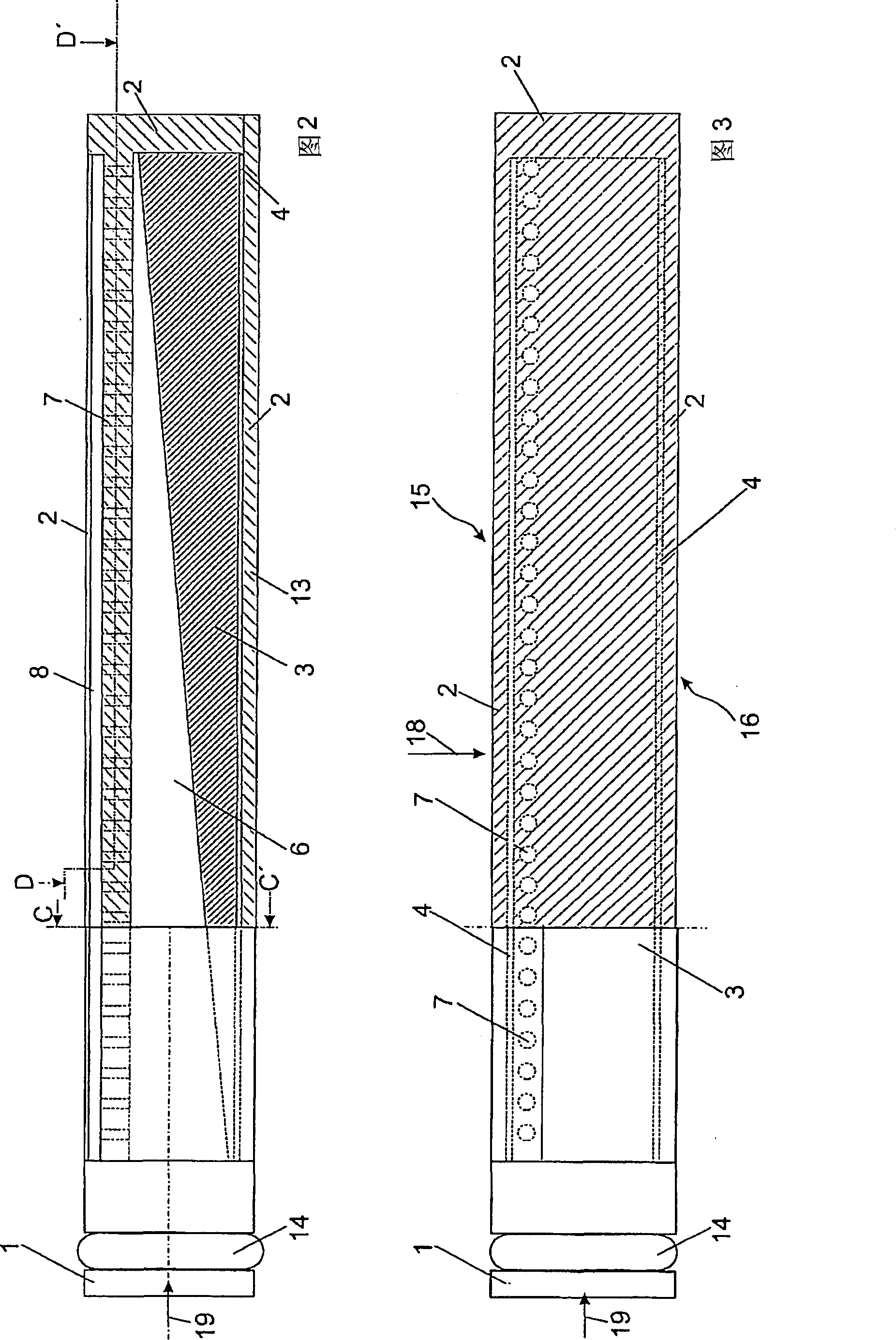

[0052] Figure 1A A nozzle arrangement according to one embodiment of the invention is shown, which is particularly suitable as a surge nozzle for an electroplating system with a horizontal run-through for printed circuit boards or printed circuit films. ). The nozzle arrangement comprises two nozzles extending along a conveying plane in which the material to be treated moves along a conveying path from an inlet area 15 to an outlet area 16 . The two nozzles are arranged directly opposite each other and mirror-symmetrically with respect to the conveying plane. A processing channel is arranged between the two nozzles, and the material to be processed can pass through the processing channel.

[0053] In each case, said nozzles comprise a housing 2 in which a nozzle opening 8 is arranged in the side facing the conveying plane. A treatment medium in the form of a treatment liquid for the treatment of the material to be treated is supplied to the nozzle through a connection openi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com