A mirror image cutting method of automobile rear panel decorative strip

A rear panel and decorative strip technology, applied in metal processing and other directions, can solve the problems of low shear efficiency and poor consistency of rear panel decorative strip shearing, and achieve the effect of ensuring stability and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

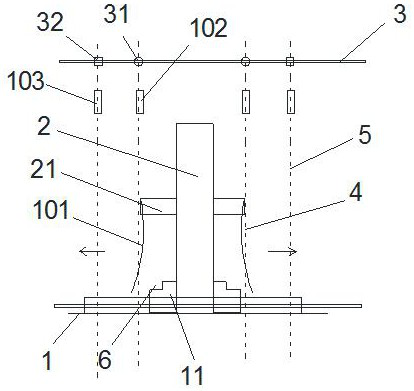

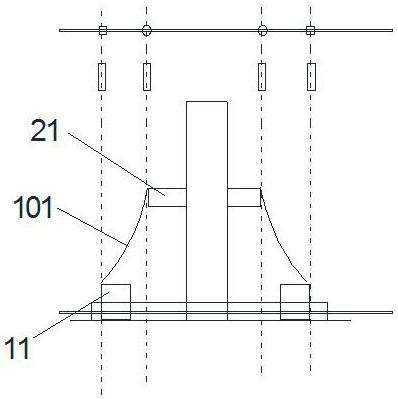

[0023] Such as Figure 1 to Figure 2 Be a kind of specific implementation mode of the present invention, comprise the following steps:

[0024] S1, preparing mirror image tooling, the mirror image tooling includes a base 1 and a support base 2 vertically arranged on the base, symmetrical suspension rods 21 are provided at both ends of the top of the support base 2, and the base 1 is provided with two sides of the support base 2. Side free fixed seat 11.

[0025] S2, set the cutting line, the top of the support seat 2 is provided with a slide rail 3, the cutting line includes two fixed cutting lines 4 and two positioning cutting lines 5, the two fixed cutting lines 4 are fixed on the slide rail 3 and located one by one Directly above the suspension rod 21 , two positioning cutting lines 5 are slidably arranged on the slide rail 3 and located outside the fixed cutting line 4 .

[0026] S3. Place the decorative strip 101 on the rear panel of the car in mirror image.

[0027] a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com