A Rolling Method for Improving Yield of Wide and Heavy Plates

A technology for wide and thick plates and good yield, applied in the direction of metal rolling, metal rolling, rolling mill control devices, etc., can solve the problems of reducing the control accuracy of the MAS rolling method and the asymmetry of the head and tail of the steel plate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

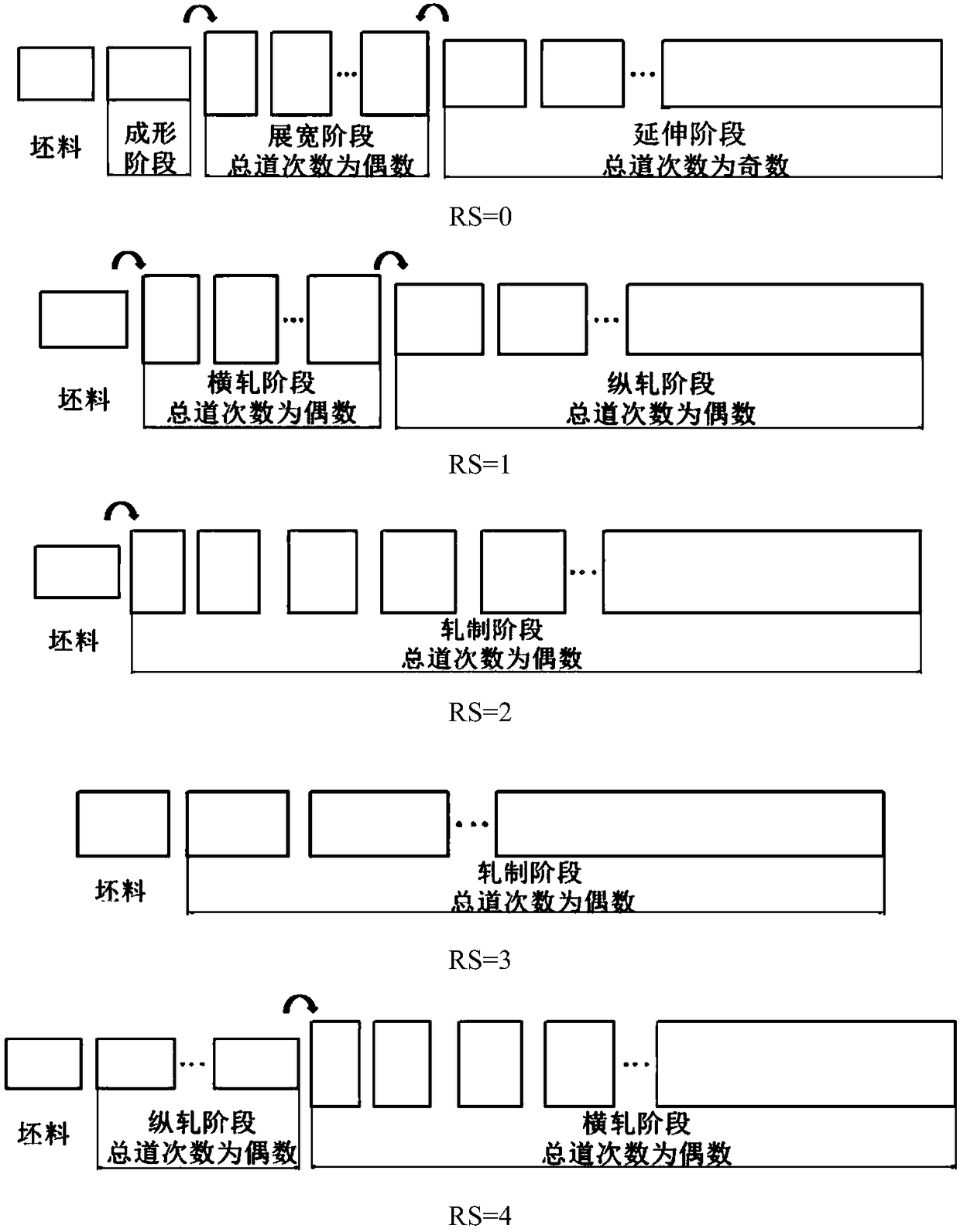

Method used

Image

Examples

Embodiment 1

[0020] Embodiment one: Q345B low-alloy high-strength steel plate;

[0021] Billet size: 260×2070×3000mm; steel plate size: 50×3330×8000mm;

[0022] Rolling method: RS=0;

[0023] Width ratio: 1.61;

[0024] MAS depth of forming pass: 3.4mm, MAS depth of widening pass: 0mm.

[0025] The rolling method is specifically shown in Table 1 below:

[0026] Table 1:

[0027]

[0028]

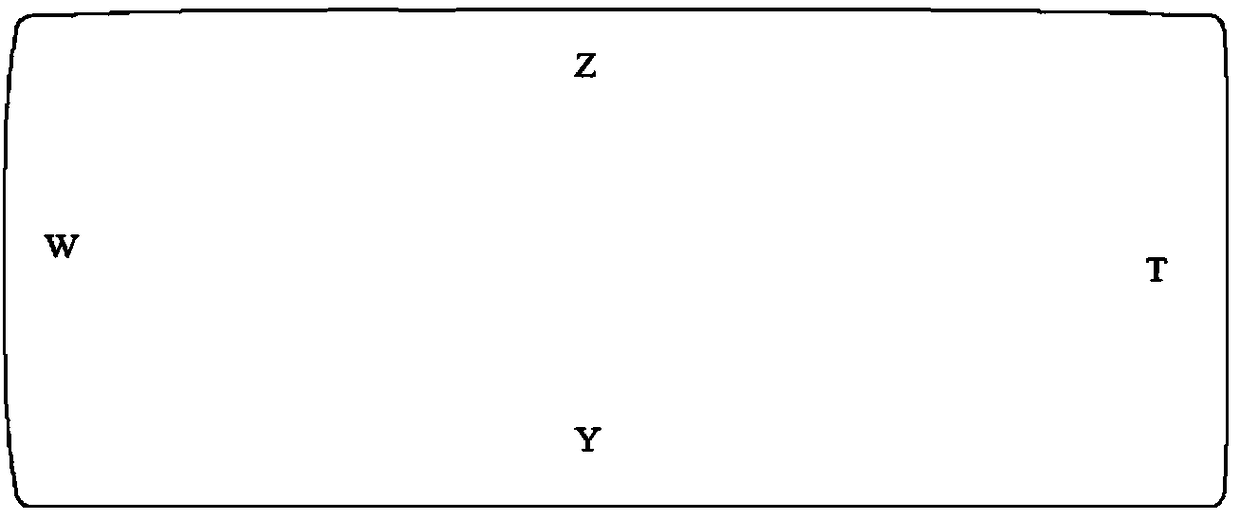

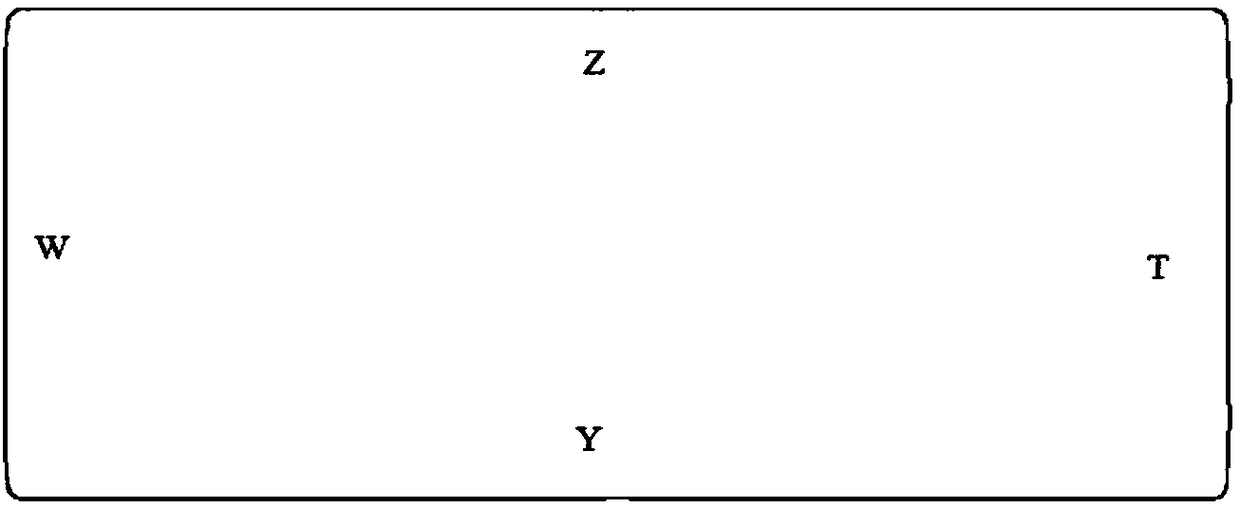

[0029] Conclusion: by Figure 2A It can be seen from and B that the edge of the steel plate produced by the conventional setting is asymmetrical, the Z side of the steel plate is slightly convex, and the Y side is slightly concave, and the steel plate is prone to camber during the subsequent rolling process. The W end of the steel plate is in a slightly convex arc, and the T end is in a slightly concave arc, that is, the W of the steel plate is slightly tongue-shaped, and the T end is slightly fishtail. However, when the arrangement of the present invention is adopted, the two sides, the head...

Embodiment 2

[0030] Embodiment two: LR-A32 ship plate;

[0031] Billet size: 260×2070×2903mm; steel plate size: 50×2860×10920mm;

[0032] Rolling method: RS=1;

[0033] Widening ratio: 1.38;

[0034] No forming pass, widening pass MAS depth: 2.4mm.

[0035] The rolling method is specifically shown in Table 2 below:

[0036] Table 2:

[0037]

[0038]

[0039] Conclusion: by Figure 3A It can be seen from and B that there is asymmetry in the edge of the steel plate produced by the conventional setting, and the Y side and the Z side of the steel plate are slightly convex arcs, but the arc convex value of the Y side is slightly larger than that of the Z side. There is asymmetry in the head and tail of the steel plate, the T end is slightly convex arc, and the W end is straight. However, when the arrangement of the present invention is adopted, the two sides, the head and the tail of the steel plate are symmetrical, the trimming value is reduced, and the finished product rate is in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com