Channel slope toe concrete key wall construction method

A construction method, the technology of concrete, applied in the direction of sheet pile walls, water conservancy projects, artificial waterways, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention is described in further detail below by embodiment, and embodiment is only used for illustrating the present invention, does not limit the scope of the present invention.

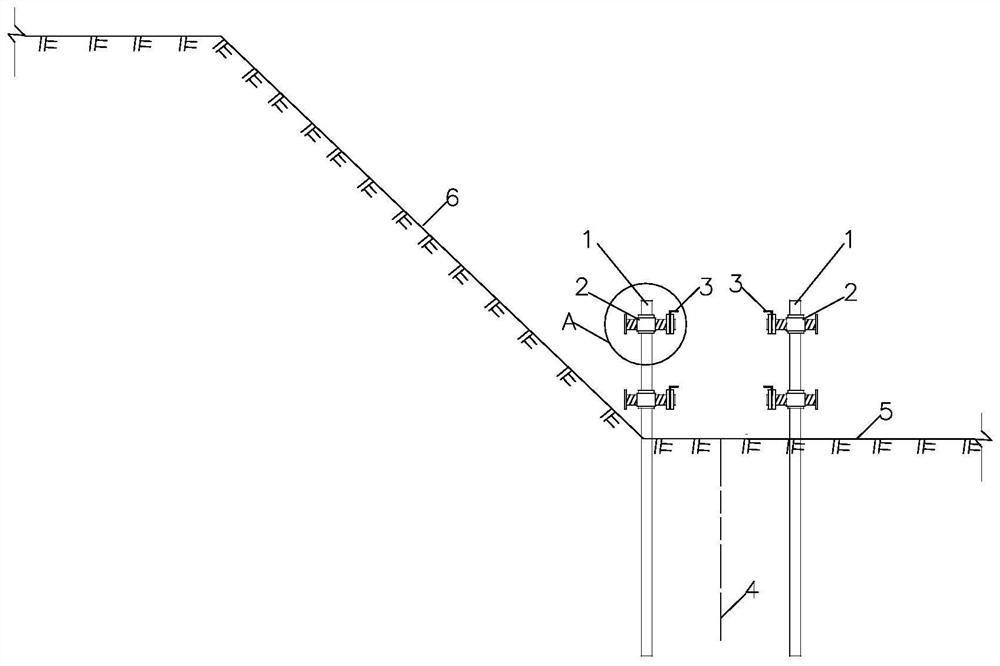

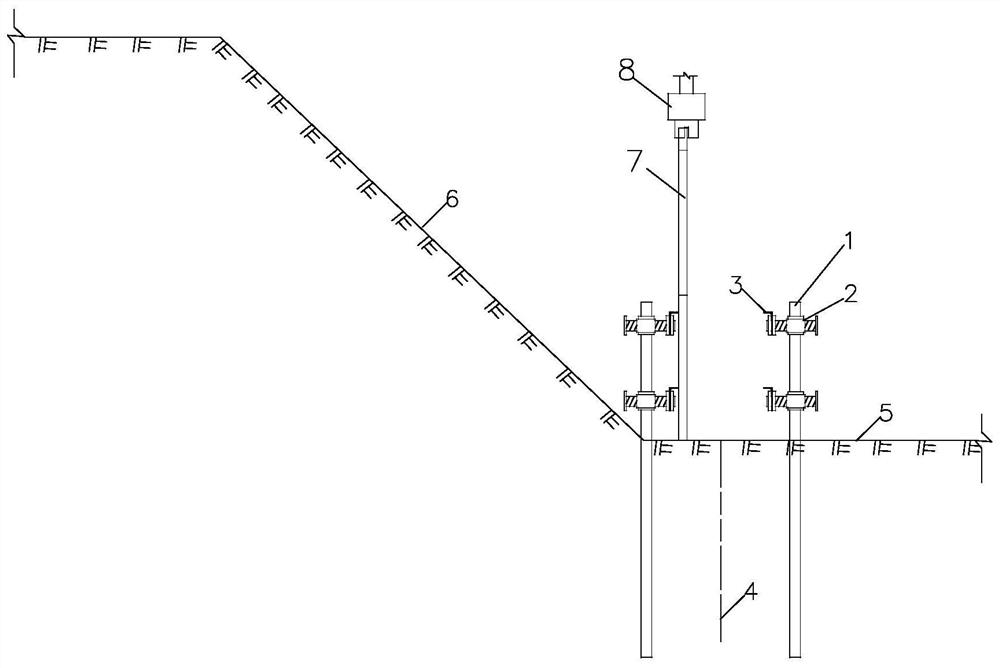

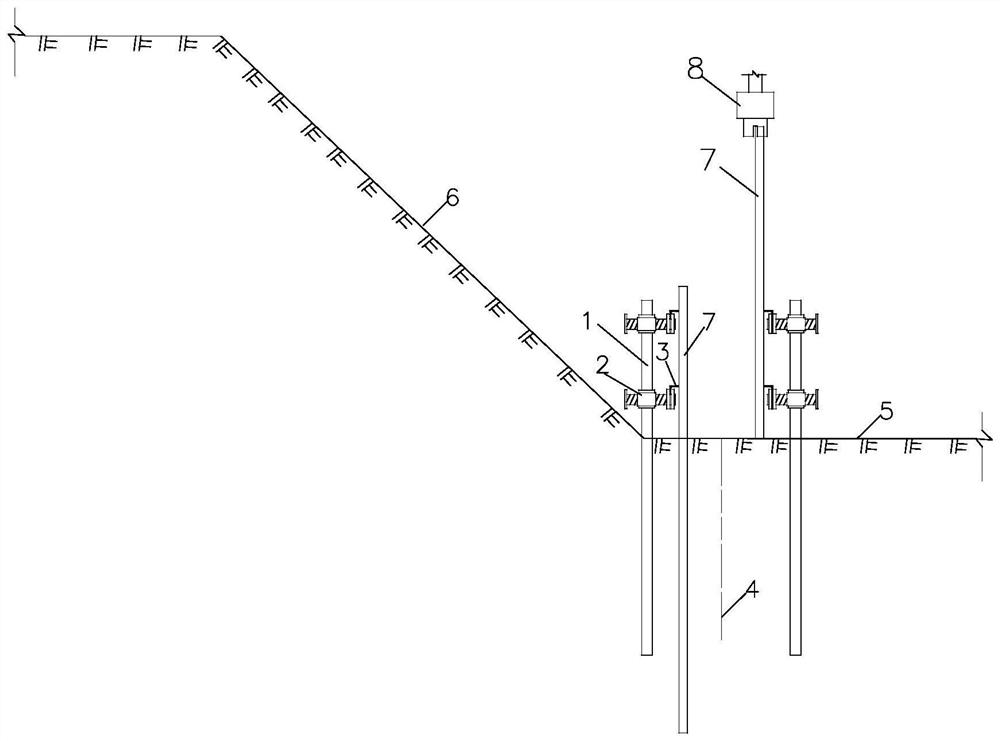

[0029] see Figure 1-12 The construction method of the concrete tooth wall at the foot of the slope includes the following steps: After the slope and the bottom of the channel are excavated and the positioning device for the steel sheet pile 7 is set, the structural lines on both sides are designed along the concrete tooth wall at the foot of the slope and The special steel sheet pile 7 is driven in through the positioning device, and the side of the multiple connected steel sheet piles 7 close to the structure line of the concrete tooth wall is a vertical plane, and the foot of the slope between the steel sheet piles 7 on both sides is excavated manually or mechanically. The earthwork within the design depth range of the concrete tooth wall, at this time, the steel sheet pile 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com