An engine mount support structure

A technology of engine suspension and support structure, which is applied in the direction of power plant, jet propulsion device, internal combustion propulsion device, etc. It can solve the problems of offset, installation gap and soft cushion can not limit the axial direction, so as to reduce the influence of pulling , prolong the belt replacement cycle, and eliminate the effect of installation gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

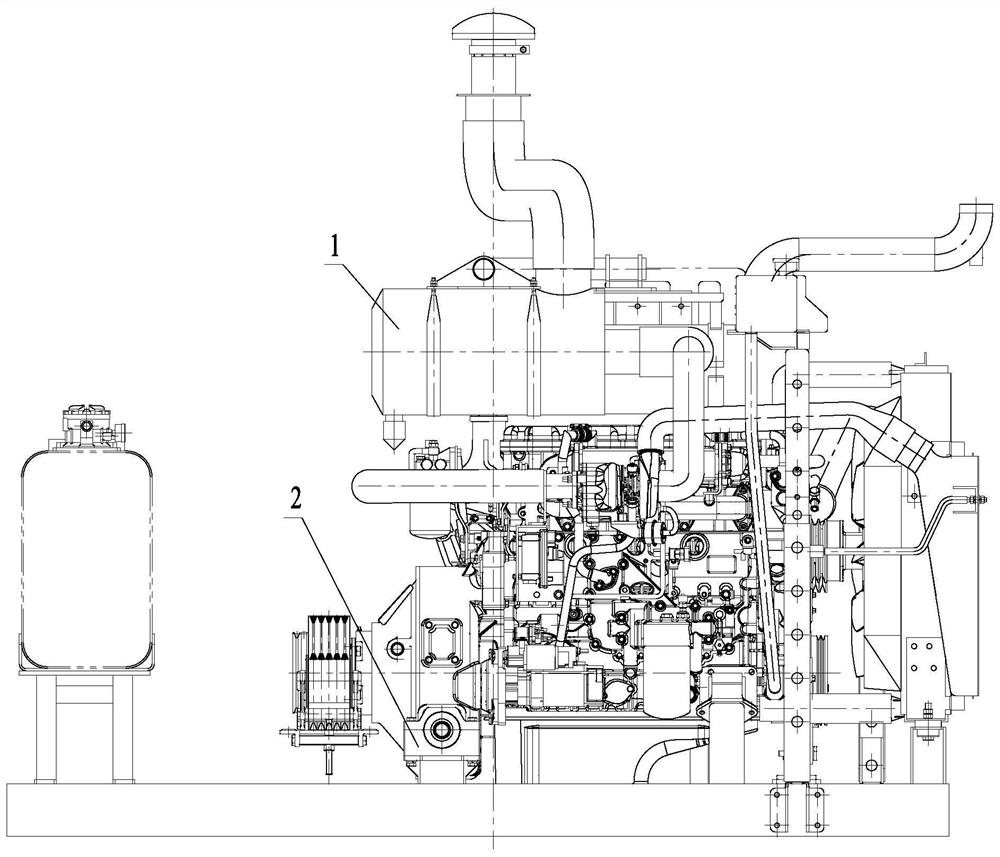

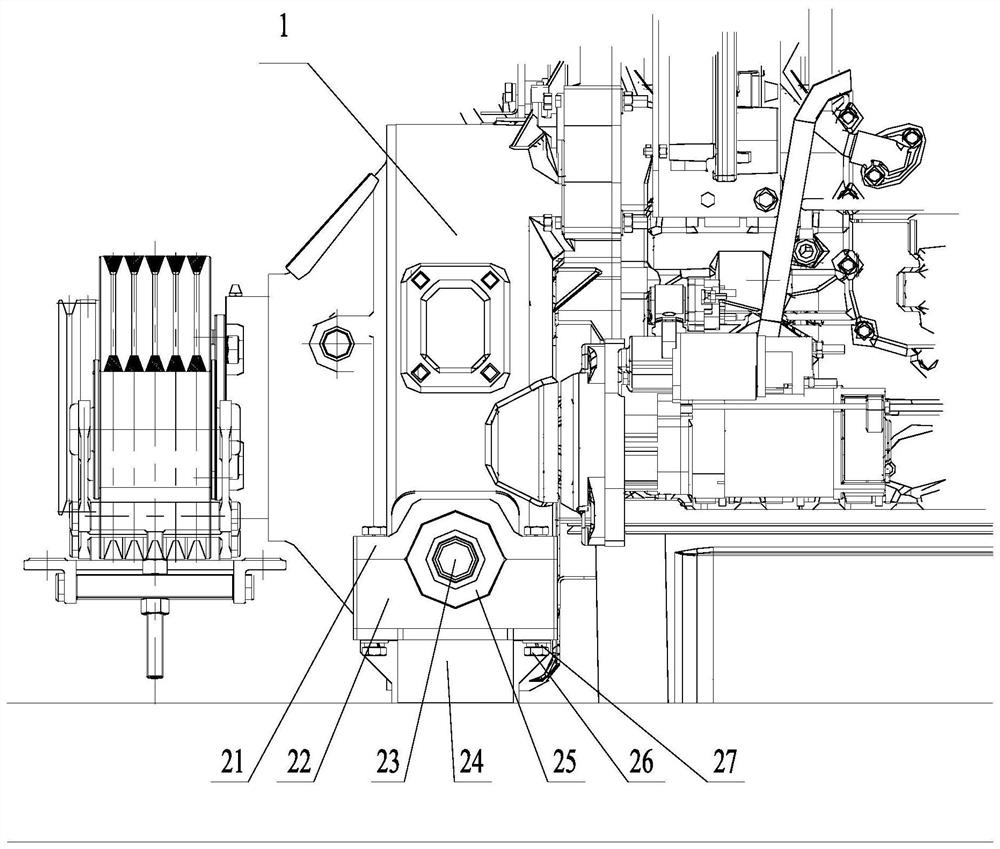

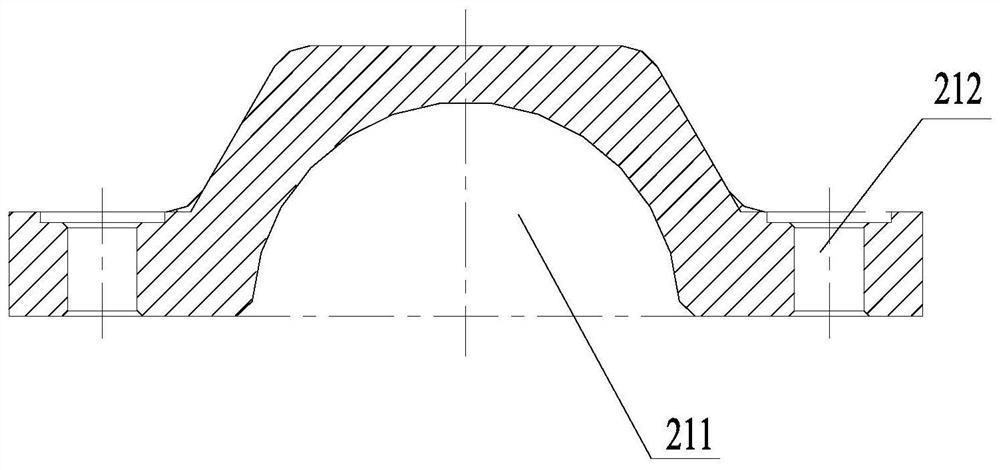

[0039] refer to figure 1 , figure 2 , Figure 4 and Figure 5 , the preferred embodiment of the present invention provides a kind of suspension support structure, is respectively arranged on the left and right sides of engine 1 rear, comprises suspension cushion 25, cushion upper cover 21, cushion lower bearing 22 and lower bearing installation Plate 24, the suspension cushion 25 includes a metal skeleton 252, natural rubber 251, the metal skeleton 252 includes a cylindrical body, the end of the cylindrical body facing the engine 1 is along the radial direction of the cylindrical body Extending outward in the direction is provided with a limit rib for limiting the axial offset of the suspe...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap