Intelligent adjusting system for axially aligning and positioning roller ring

An axial alignment and intelligent adjustment technology, which is applied in the parts of grinding machine tools, the control of workpiece feed motion, and machine tools designed for grinding workpiece rotating surfaces. Problems such as meeting the standards, not meeting the standards, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

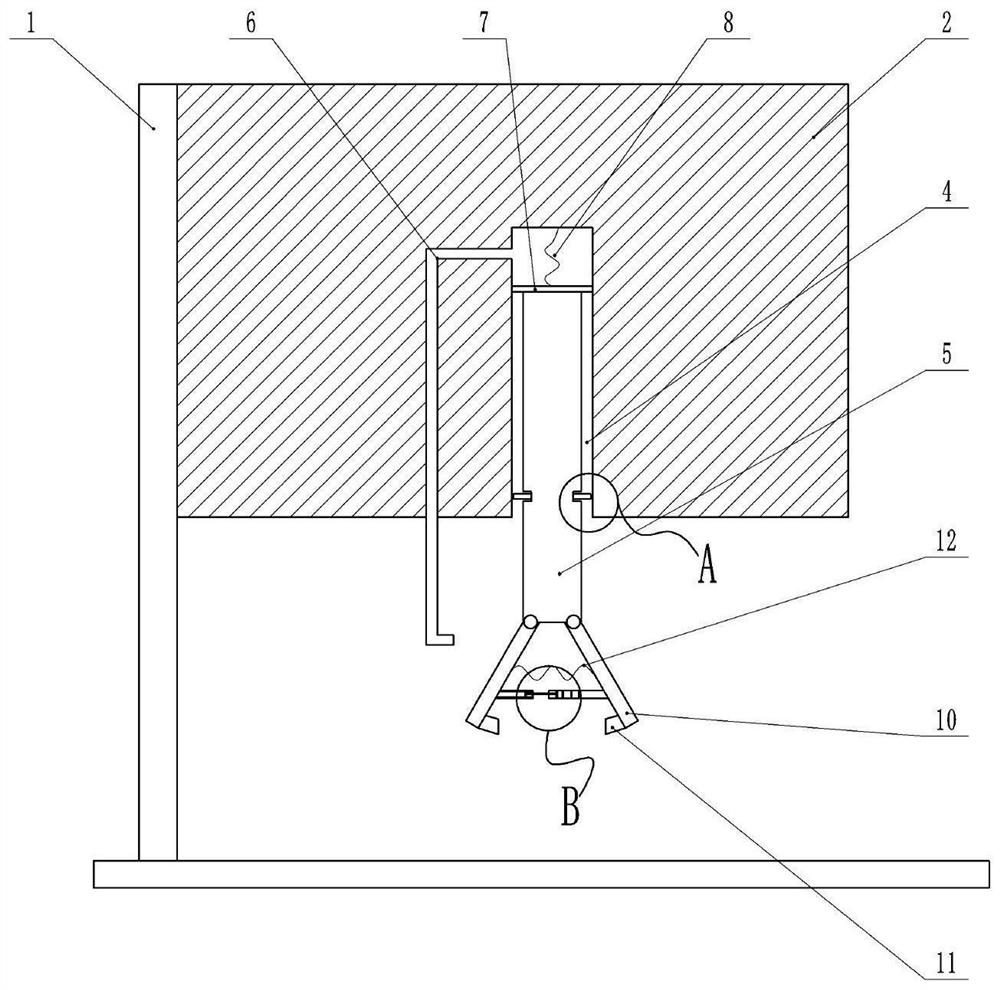

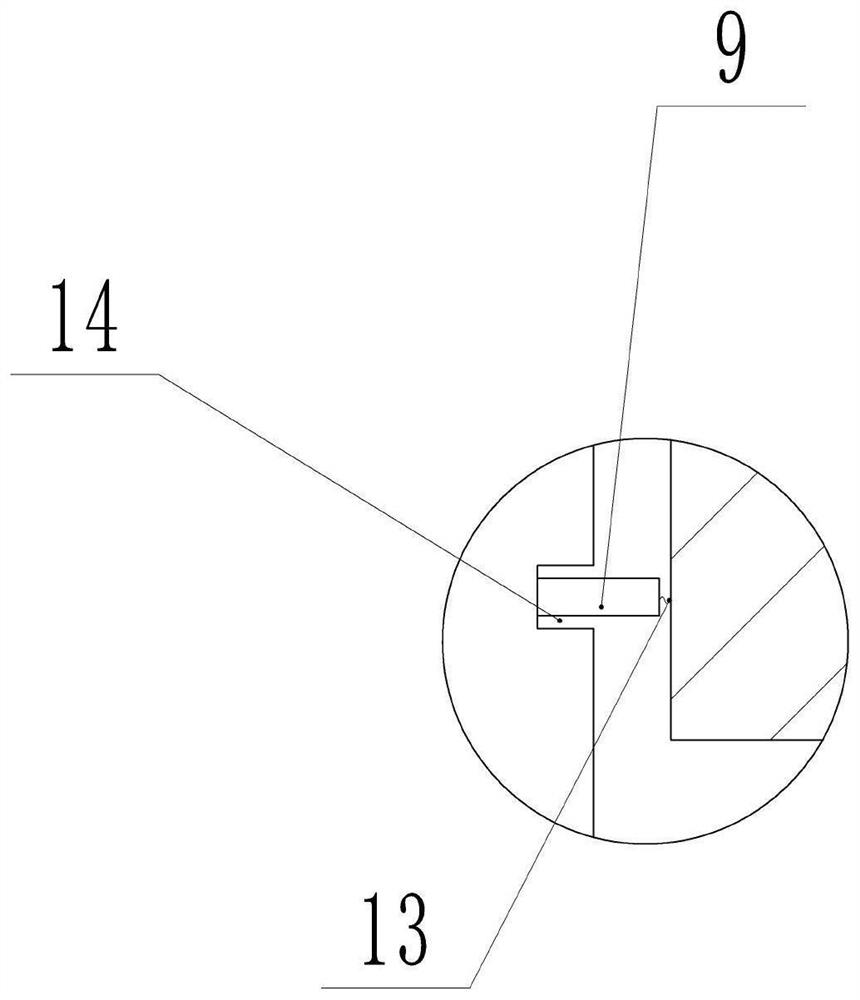

[0033] as attached figure 1 , attached figure 2 And attached image 3 Shown:

[0034] The frame 1 is provided with a clamp 2 for clamping the roll ring 22, and a suspension ring is provided directly above the clamp 2, which can lift the clamp 2 to ensure that the clamp 2 can be lifted or lowered by a machine or a lifting mechanism. The clamp 2 is provided with a cavity 4 and a connecting rod 5, and a groove 14 is provided on both sides of the connecting rod 5, and two spacer blocks 9 are arranged in the cavity 4, and the two spacer blocks 9 are connected with the cavity respectively. A third spring 13 is connected between the side walls of 4 , and the shape and position of the groove 14 and the limit block 9 are adapted to each other. The lower end of the connecting rod 5 is hinged with one end of the clip hook 10, one end of the two clip hooks 10 is hinged with the lower end of the connecting rod 5, and the other end can swing to adjust the closing angle of the two clip h...

Embodiment 2

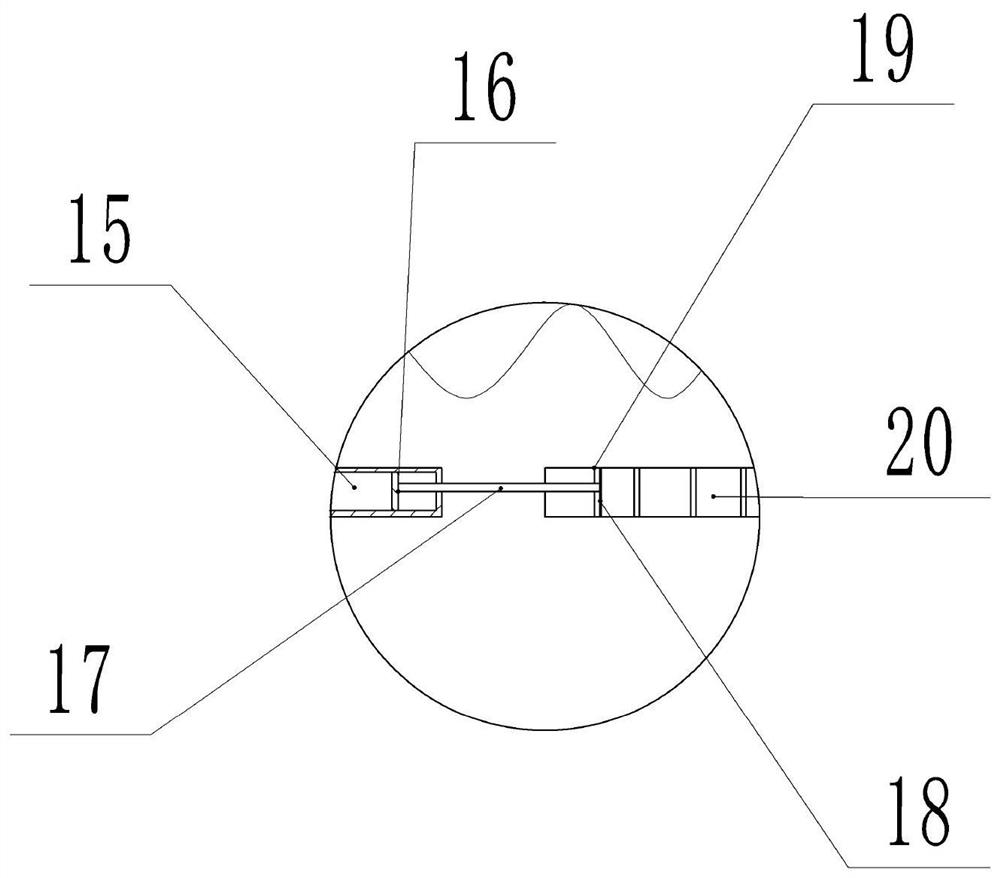

[0044] as attached Figure 4 Shown:

[0045] The difference from Embodiment 1 is that this embodiment also discloses a process of grinding and spraying oil after the heat treatment of the roller ring 22. The barbs 11 are provided with rotating wheels 23 connected to each other. When the roller ring 22 is clamped, the runners 23 is in contact with the inner wall of the roller rim 22, the fixture 21 is provided with an oil injection pipe for spraying lubricating oil to the roller rim 22, the oil injection pipe is provided with a solenoid valve, and the fixture 21 is also provided with a grinding wheel for grinding the roller rim 22 21, the grinding wheel 21 is installed in rotation on the clamp 2, and the clamp 21 is provided with a driving mechanism 3 that drives the grinding wheel 21 to move up and down. The driving mechanism 3 can choose to drive the cylinder 15, etc., and the grinding wheel 21 is set correspondingly to the position of the clamp hook 10. To ensure that the g...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap