A rolling mill beam hoisting tool

A technology for hoisting tools and beams, which is applied in the direction of transportation and packaging, load hanging components, etc., can solve the problems of surrounding personnel injury, time-consuming and laborious, beam tilting, etc., and achieve the effects of improving safety, convenient use, and convenient and quick operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

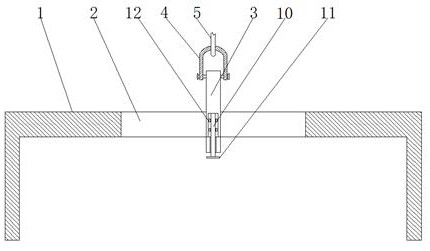

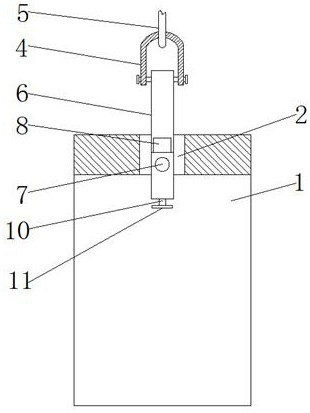

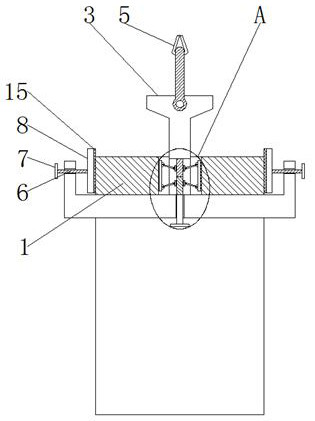

[0019] A rolling mill beam hoisting tool, comprising a rolling mill beam 1, a horizontal groove 2 penetrating through its upper and lower side walls is opened on the rolling mill beam 1, a movable plate 3 is inserted in the horizontal groove 2, the movable plate 3 is arranged in an inverted T shape, and the movable plate 3 A shackle 4 is arranged on the upper side, and the top surface of the shackle 4 is arranged in an arc shape. The shackle 4 is flexibly connected with the movable plate 3, which is convenient for hoisting. The side walls are all provided with threaded holes, and the first threaded rod 6 is movably connected with the first threaded rod 6 in the threaded hole. One end of the wheel 7 is movably connected with a riser 8, and the side wall of the riser 8 away from the first threaded rod 6 is fixedly connected with a leather pad 15, so that the fixing is firm and stable, and the corner of the movable plate 3 is provided with a movable groove 9. Groove 9 runs throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com