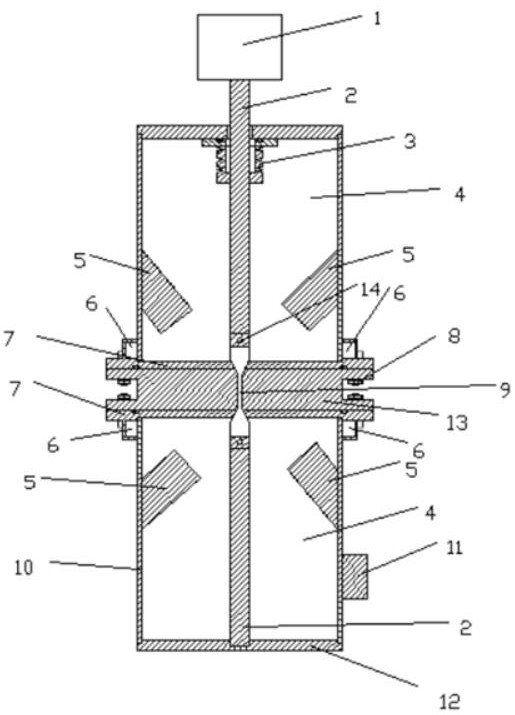

Microscopic CT in-situ tensile testing device

A testing device and in-situ stretching technology, applied to measuring devices, applying stable tension/pressure to test the strength of materials, instruments, etc., can solve the problems that the control accuracy and control range are difficult to meet the requirements, and the sample is not applicable, etc., to achieve The effect of small volume, simple structure and high experimental precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In view of the deficiencies of the existing technology, the purpose of the present invention is to provide a micro-CT in-situ micro-CT that can precisely control the temperature and pressure of the sample during the CT stretching experiment, and has a simple structure, small volume, and high experimental accuracy. Tensile testing device.

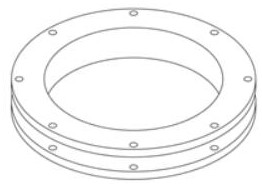

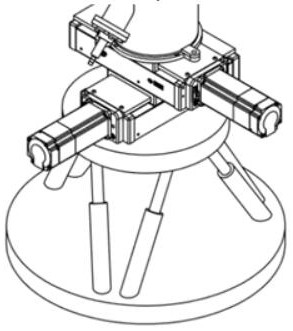

[0023] Specifically, the micro-CT in-situ tensile test device of the present invention includes a sealed experimental cavity, upper and lower stretch rods, a control system and an adjustment system; the sealed experimental cavity has a cavity door for taking and placing samples , and a circle of transparent windows that allow X-rays to pass through the middle section of the sealed experimental chamber; the upper and lower stretching rods respectively penetrate the top and bottom of the experimental chamber and are dynamically and sealedly connected with the sealed experimental chamber; the control system includes a pressure control sys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com