Spring conveying device and bagged spring production equipment

A conveying device and circular conveying technology, which is applied in the field of bagged spring manufacturing, can solve the problems of uneven conveying and unreliable spring separation, and achieve the effect of reliable separation and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

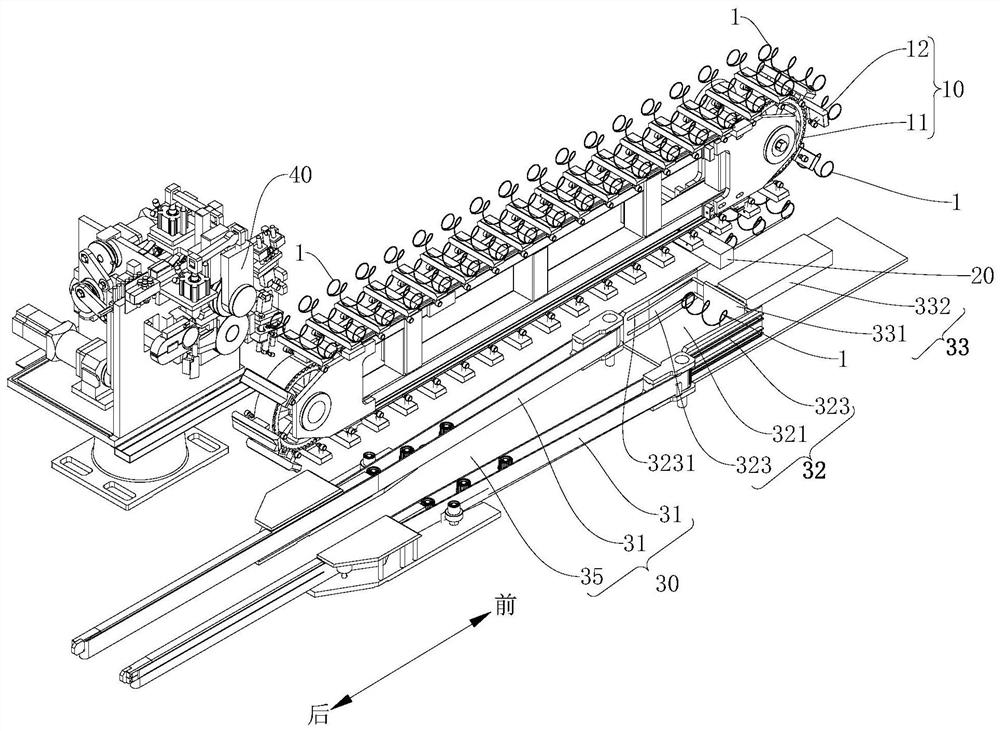

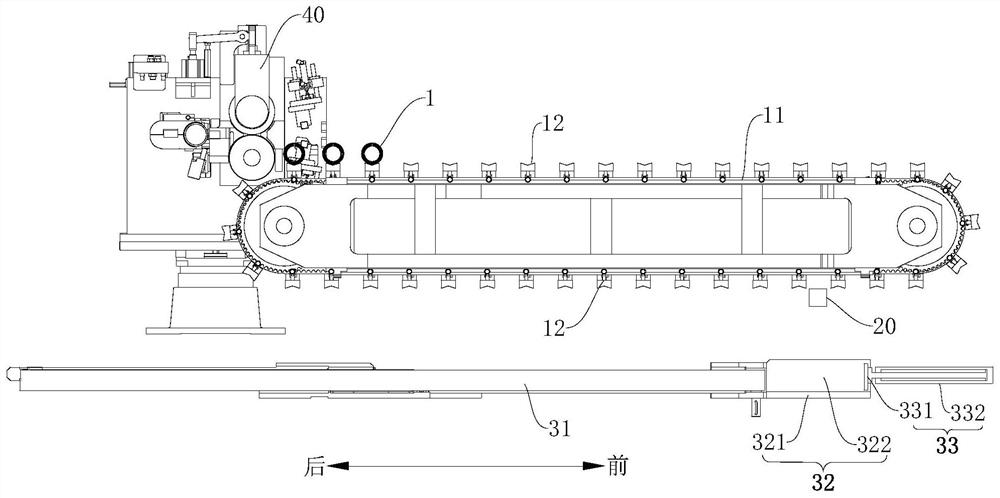

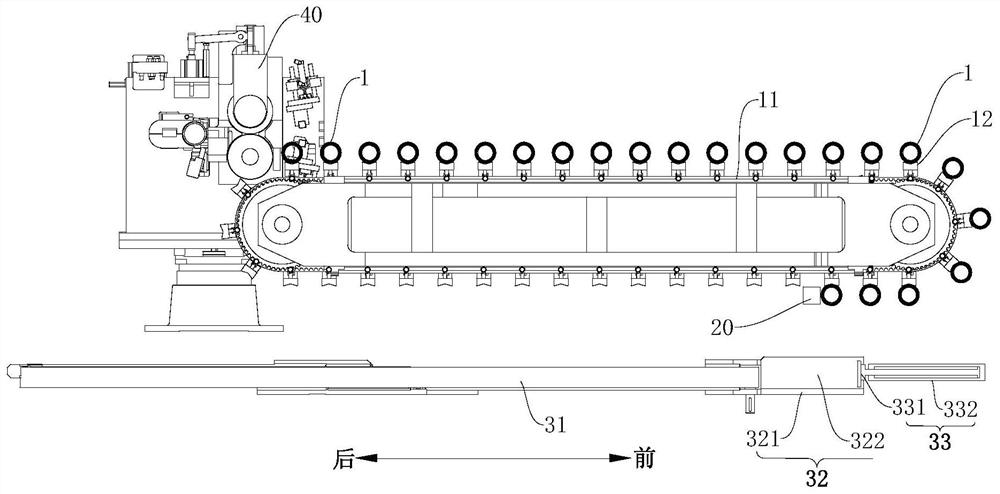

[0046] Embodiments of the invention are described in detail below, examples of which are illustrated in the accompanying drawings. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

[0047] The related technology discloses a pocket spring production compression conveying mechanism, in which the spring conveying mechanism conveys the spring between the two baffles of the spring compression conveying mechanism and drives the spring to move from the end with a larger distance between the two baffles to the At the other end where the distance between the two baffles is small, the spring is gradually compressed as the distance between the two baffles gradually decreases. After the spring is compressed to a certain extent, it is separated from the spring conveying mechanism and conveyed by the spring compression conveying mechanism. In other words,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com