External electro-hydraulic combined type vehicle posture adjusting unit

An adjusting unit and compound technology, applied in the field of hydraulic machinery, can solve the problems of large occupied space, poor maintainability, complex structure, etc., and achieve the effects of low renovation cost, convenient maintenance and replacement, and improved space utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the purpose, content and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below.

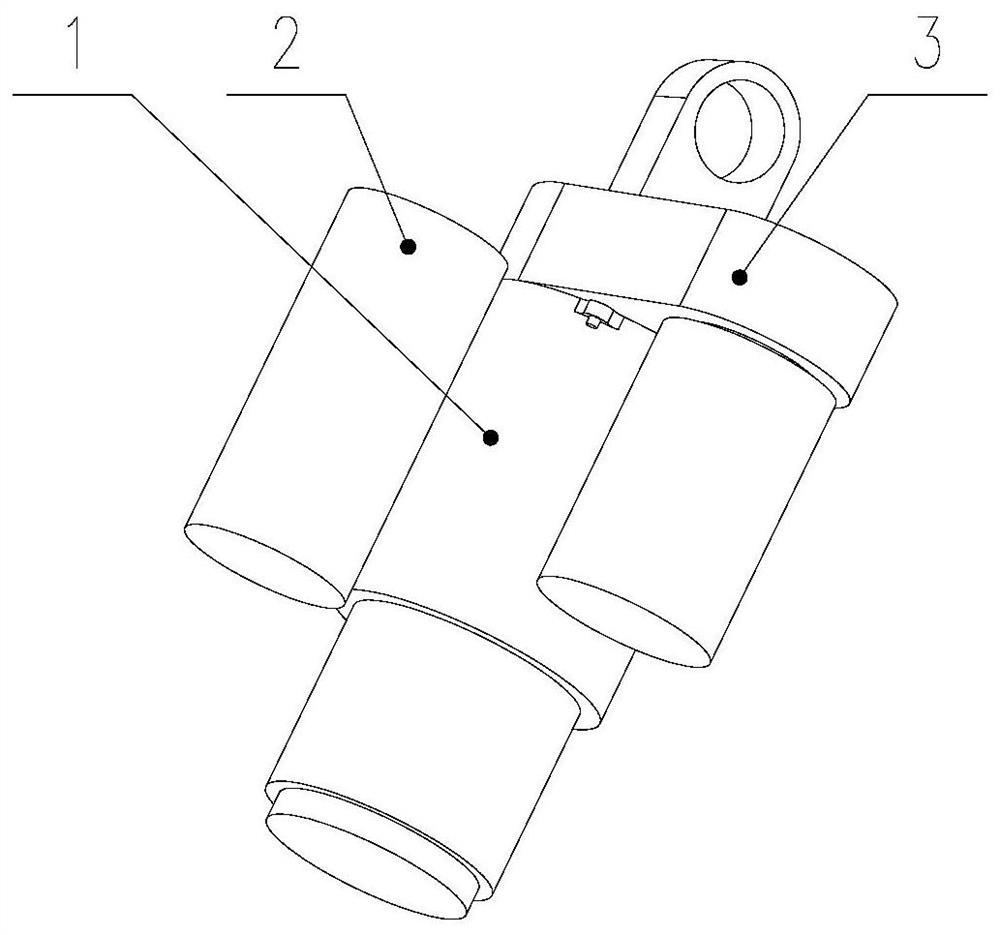

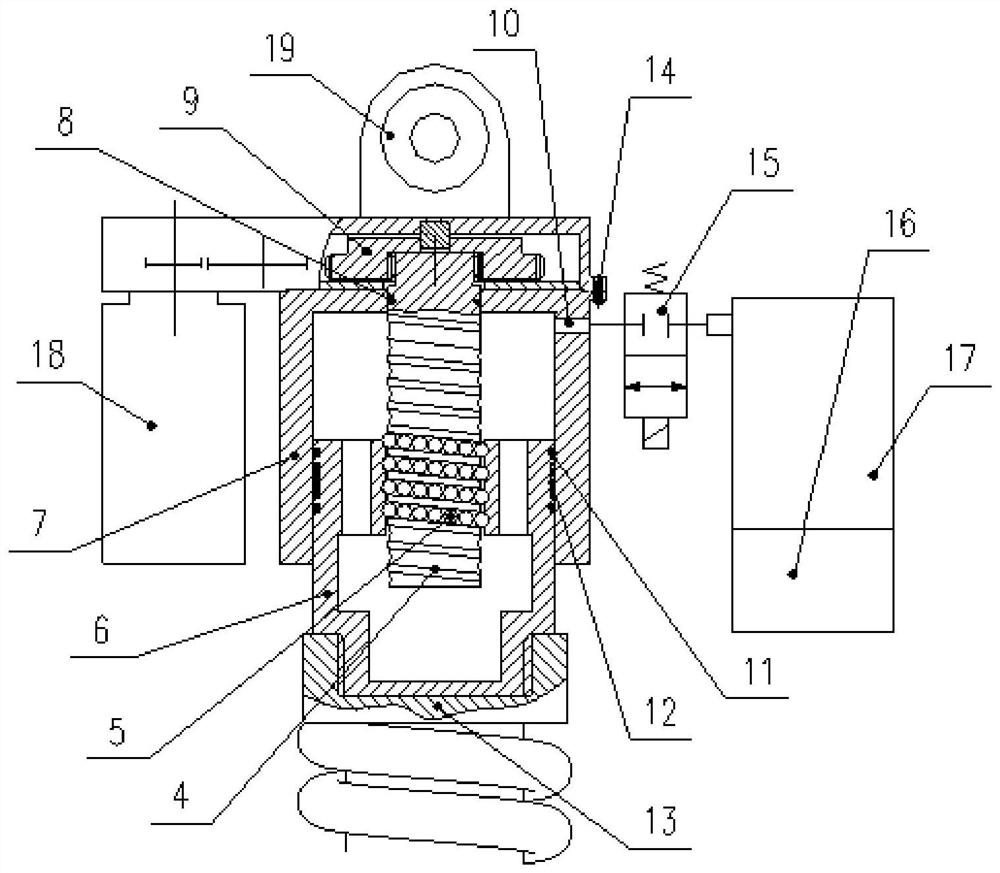

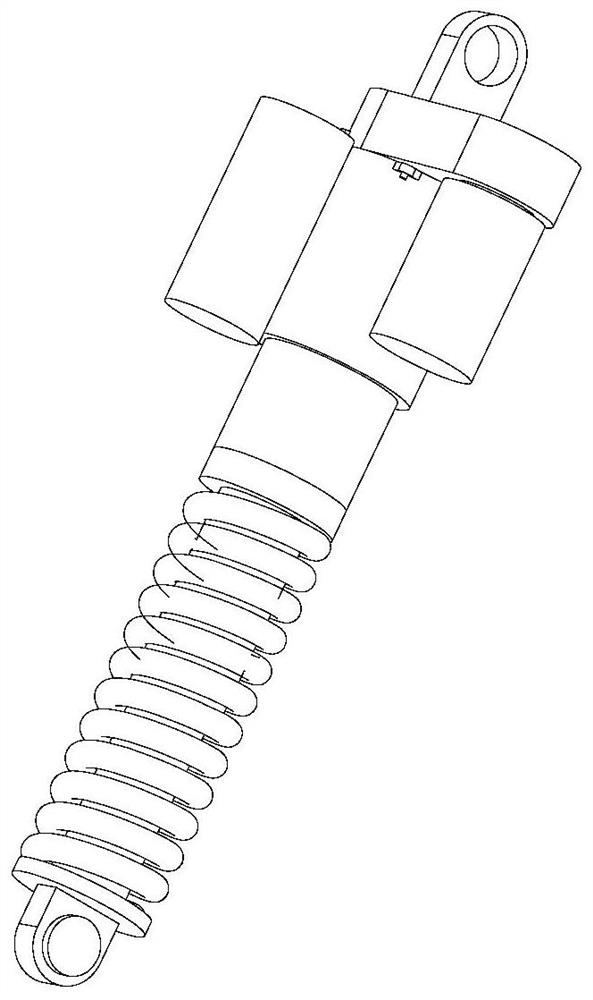

[0016] An external electro-hydraulic composite vehicle attitude adjustment unit proposed by the present invention includes a main body actuator 1, an additional oil chamber 2 is installed on one side of the main body actuator 1, and a driving transmission mechanism 3 is arranged on the other side; :

[0017] The main body actuator 1 includes a ball screw 4, a ball 5, a nut piston 6, and a cylinder 7. A seal 8 is arranged in a groove on the side of the upper end of the ball screw 1, and the outer teeth of the upper end of the ball screw 4 pass through the top of the cylinder 7 and The inner tooth surface of the inner tooth 9 at the output end of the drive transmission mechanism 3 meshes, and the lower end of the ball screw 4 and the upper end of the nut piston 6 are matched togethe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com