Equipment mounting seat for power supply department

A technology for mounting seats and equipment, which is applied to mechanical equipment, lifting devices, lifting frames, etc., and can solve the problems of single height adjustment method and small adjustment range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

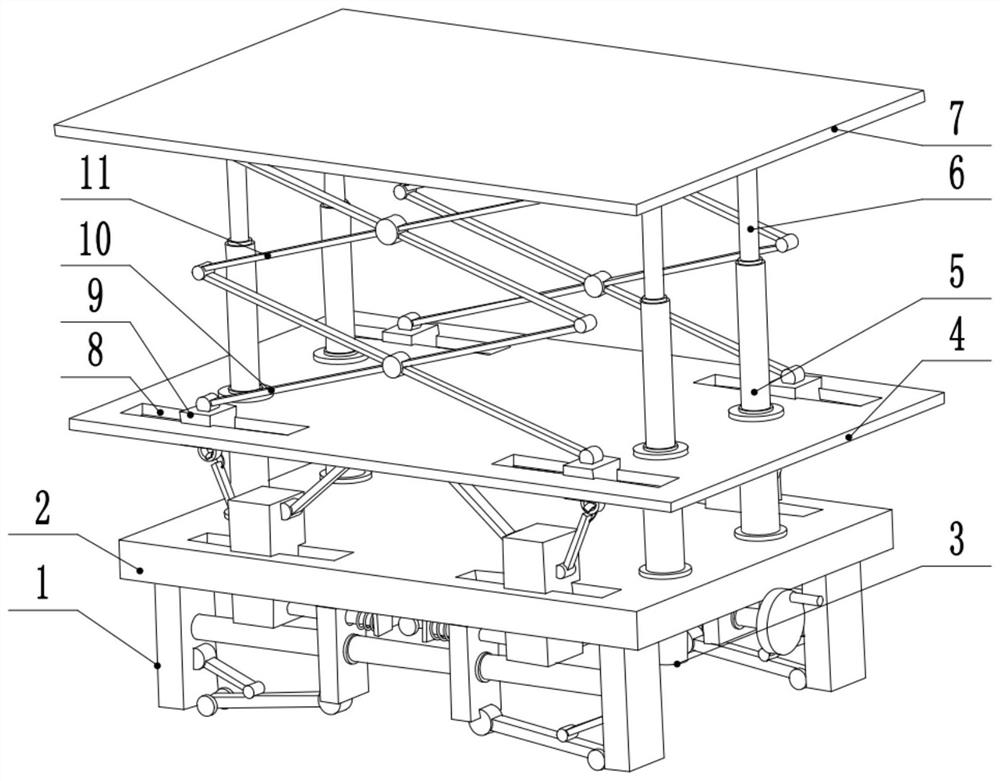

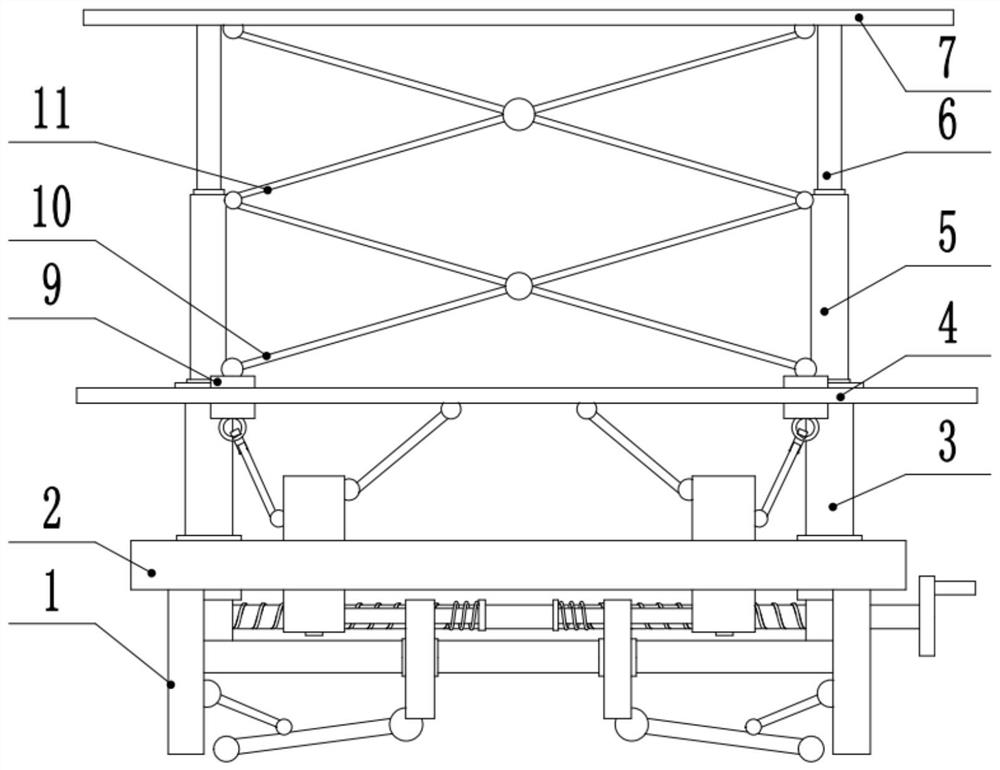

[0028] see Figure 1-5 , a device mounting seat used by a power supply department, including a support plate 4, the left and right sides of the support plate 4 are provided with sliding sleeves 3, the upper part of the sliding sleeve 3 is slidably connected to the lower part of the first sliding rod 5, and the bottom of the first sliding rod 5 The upper part is slidably connected to the bottom of the second sliding rod 6 , the upper end of the second sliding rod 6 is fixedly connected to the lower surface of the supporting plate 7 , and the lower part of the sliding sleeve 3 is slidably connected to the left and right sides of the bottom plate 2 .

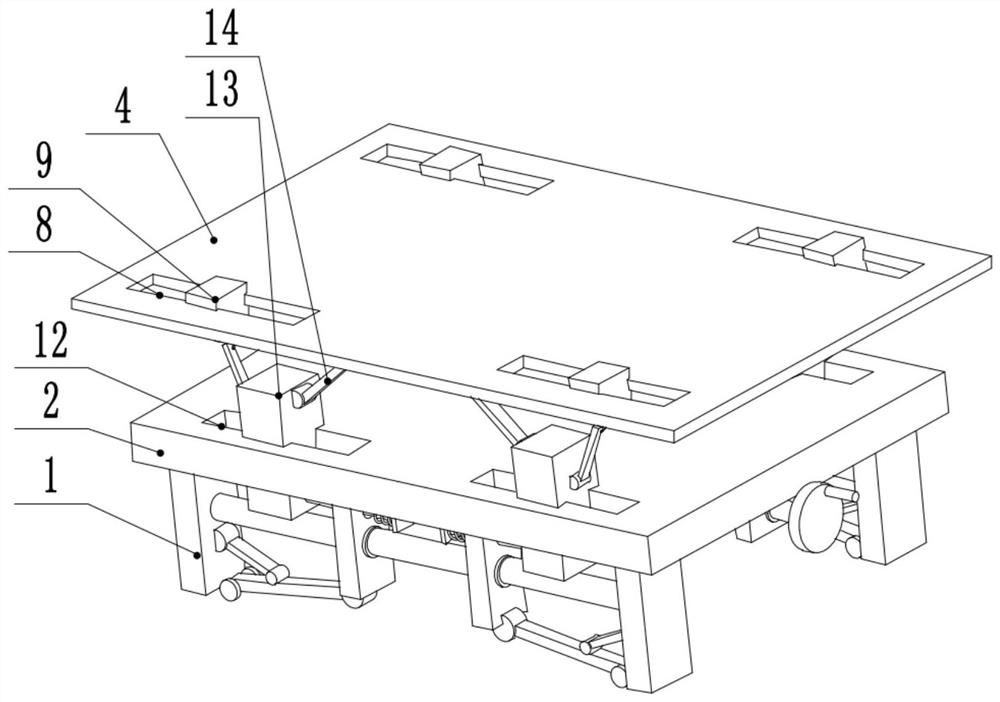

[0029] The left and right sides of the lower surface of the base plate 2 are provided with bearing blocks 28, and the middle part of the bearing blocks 28 is rotated to connect the left and right ends of the screw mandrel 27. The left and right sides of the screw mandrel 27 are provided with threads with opposite rotation directions...

Embodiment 2

[0032] see Figure 5 , the other content of this embodiment is the same as that of the first embodiment, except that a spring 22 is provided on the side of the limiting block 23 away from the center of the device. In order to further improve the shock absorption effect of the device, a spring 22 is arranged on the limit block 23, so that the spring 22 can play a shock absorbing effect in the middle when the limit block 23 pulls the third slider 24 to move , so that during the movement of the supporting caster 1 wheel, if the road surface is uneven, the deformation of the spring 22 can be used to offset the vibration of the road surface in time, thereby achieving the effect of shock absorption.

[0033]During the implementation of the present invention, the runner 29 is rotated, and the runner 29 drives the screw mandrel 27 to rotate. Since the left and right sides of the screw mandrel 27 are provided with threads with opposite directions of rotation, when the screw mandrel 27 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com