Machine head pelletizing device for screw extruder

A technology of screw extrusion and granulation, which is applied in the field of granulation equipment, can solve the problems of inconvenient disassembly, maintenance and replacement of hobs, dirty water, and affecting work efficiency, etc., to achieve convenient granulation processing, convenient orientation, and structural optimization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

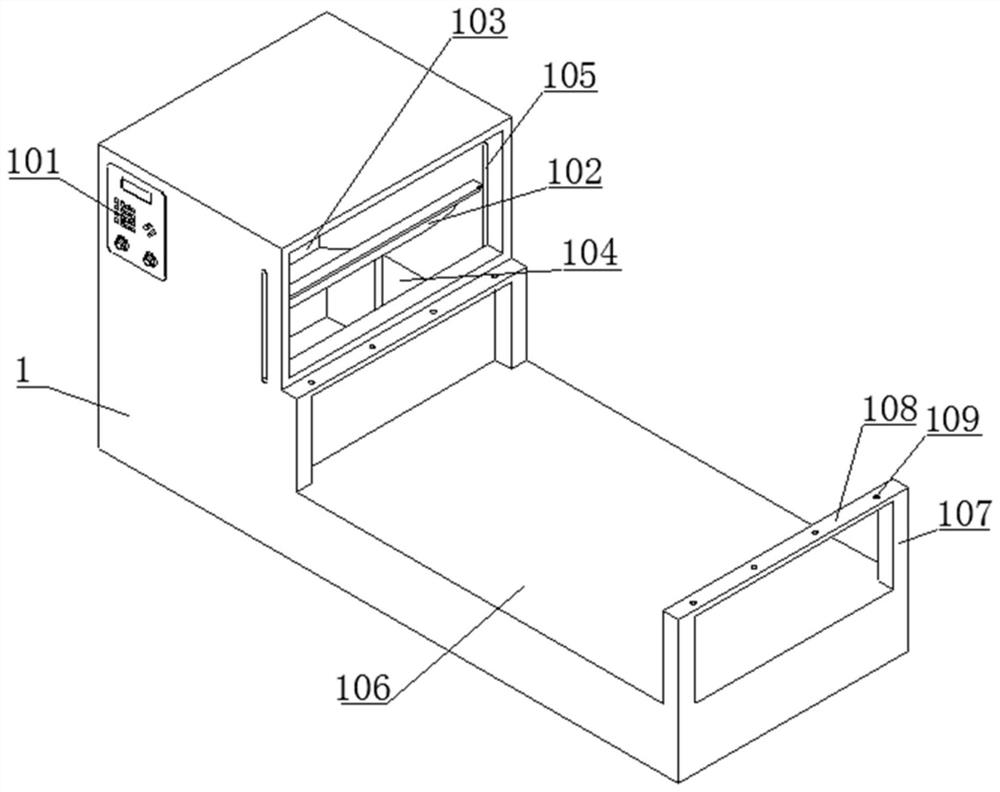

[0053] refer to Figure 9 As shown: the cutting head 8 of this embodiment includes a cutter head 81, a rocker 82, an adapter 83 and a guide roller 84. The top of the cutter head 81 is provided with a first blade 811, and the first blade 811 fits into the cooling box 2 and is inserted into the body 1, the bottom of the cutter head 81 is provided with a second bearing 814, the top of the rocker 82 is aligned with the position of the second bearing 814, and a second connecting shaft 821 is provided, and the second connecting shaft 821 and the second bearing 814 are interferingly connected together , and the bottom end of the rocker 82 is provided with a third bearing 822, and the position of the adapter 83 aligned with the third bearing 822 is provided with a third connecting shaft 831, the third connecting shaft 831 and the third bearing 822 are interference-connected together, and the adapter 83 is provided with a connection port 833 near the bottom end, and the position where ...

Embodiment 2

[0057] refer to Figure 9 Shown: the pelletizing head 8 of the present embodiment comprises cutter head 81, rocking bar 82, adapter 83 and guide roller 84, cutter head 81 middle part is provided with cutting hole 812, and cutting hole 812 is rectangular, and cutting hole 812 top and the bottom are provided with a second blade 813, the two second blades 813 are symmetrically arranged, the second blade 813 fits the end face of the cooling box 2 inserted into the body 1, the bottom of the cutter head 81 is provided with a second bearing 814, a rocker 82 A second connecting shaft 821 is arranged at the position where the top end is aligned with the second bearing 814, and the second connecting shaft 821 and the second bearing 814 are interference-connected together, and the bottom end of the rocker 82 is provided with a third bearing 822, and the adapter 83 is aligned with the second bearing 814. The position of the third bearing 822 is provided with a third connecting shaft 831, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com