Method and device for promoting scramjet engine to achieve starting ignition

A scramjet and engine technology, applied in combustion methods, combustion chambers, combustion equipment, etc., can solve the problems affecting the combustion performance of the engine, and achieve the effect of promoting the realization of starting ignition, promoting efficient mixing, and ensuring release.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

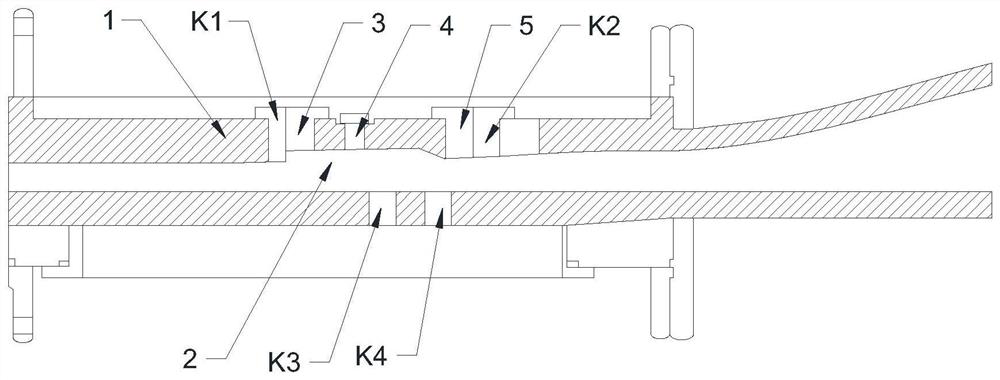

[0026] see figure 1 , a method for promoting scramjet engine to realize start-up ignition, injecting air into the engine vertically to the direction of air flow on one side of the inner wall surface of the scramjet flame stabilizer, and the air flow rate is 15% to 30% of the air flow rate at the engine inlet %, the distance between the injection air position and the engine flame stabilizer position is 10% to 20% of the total length of the engine.

[0027] In this embodiment, the rear part of the scramjet flame stabilizer implements air jet injection, the air is air at a normal temperature of 295K, and the air flow rate is 15% to 30% of the air flow rate at the engine inlet.

[0028] The device used in this embodiment to promote the start and ignition of the scramjet engine includes a flame stabilizer arranged at the front end of the scramjet combustion chamber. The flame stabilizer is provided with a plurality of fuel injection blocks. There are a plurality of nozzle holes co...

Embodiment 2

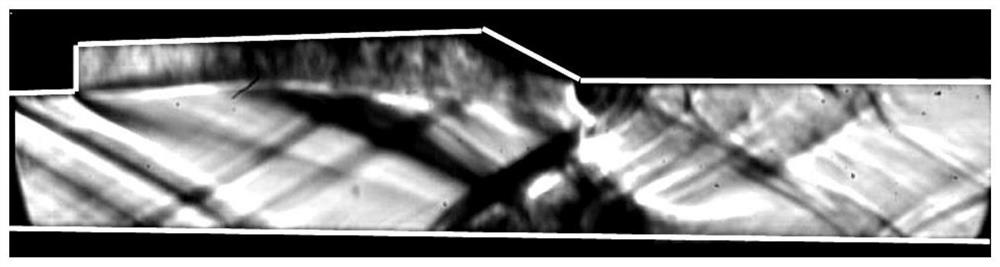

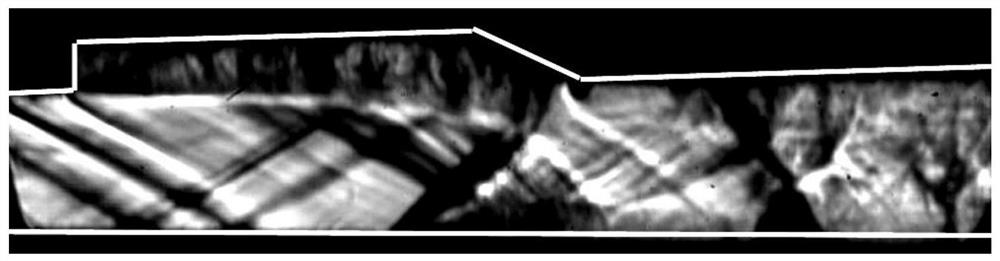

[0032] see Figure 1-7 , the present embodiment will test and compare the similarities and differences of the scramjet flow field structure, start ignition time and flame distribution with and without the action of jet air, to verify the practical application effect brought by the present invention.

[0033] In this embodiment, the configuration of the engine is as figure 1 As shown, the engine model 1 includes a flame stabilizer located at the front end of the combustion chamber, the inlet interface of the isolation section of the combustion chamber is 30mm×150mm, and the total length of the model is 1073.19mm. Engine model 1 uses kerosene as fuel to inject through the fuel injection block. The total air flow rate of the air jet tooling block 5 at normal temperature is about 27.2% of the inlet engine flow rate. Cavity) entrance is about 198.16mm, accounting for about 18.5% of the total length of engine model 1. The upper wall of the flame stabilizer is a cavity 2, and two s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com