Hypersonic mechanical transmission frequency modulation pulse injection device and method

A mechanical transmission and hypersonic technology, applied in the direction of mechanical equipment, combined engines, ramjet engines, etc., can solve the problem that the influence of pressure increase is difficult to control, it is not enough to achieve a high degree of fuel mixing, and the mixing process of fuel and incoming flow is long and other problems, to achieve the effect of eliminating the shear layer, avoiding the phenomenon of rich oil flameout, and good crushing and atomization effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

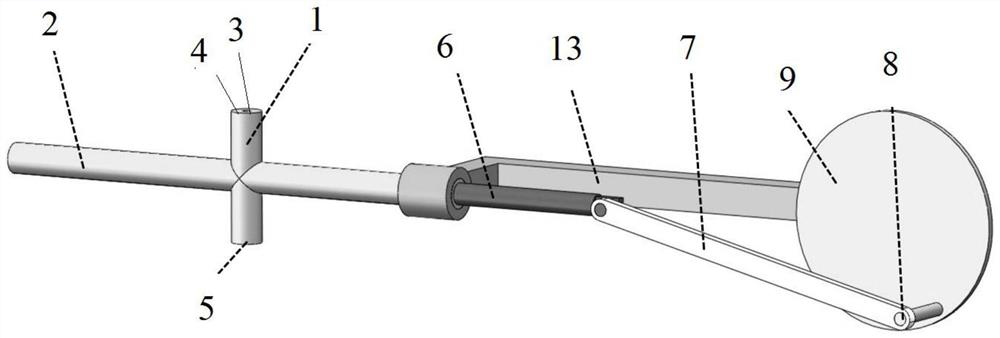

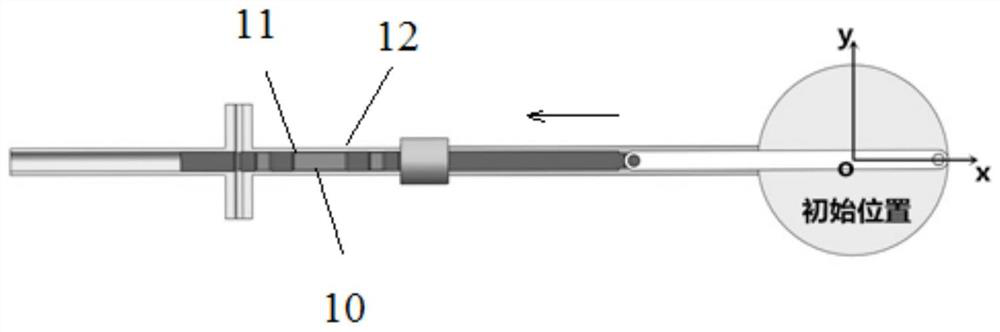

[0040] A hypersonic mechanically driven frequency-modulated pulse injection device, comprising: a longitudinal main body shell 1, a transverse main body shell 2 vertically crossing the longitudinal main body shell 1, an axis 6 is arranged concentrically inside the transverse main body shell 2, and the right end of the axis 6 is connected to a transmission The left end of the rod 7 is hinged, and the right end of the transmission connecting rod 7 is hinged on the high-speed bearing 8 on the driven turntable 9. The driven turntable 9 rotates under the drive of the motor, and the transmission connecting rod 7 drives the axis 6 to reciprocate in a straight line inside the horizontal main body shell 2. movement, a fuel channel 3 is provided inside the longitudinal body shell 2, and the two ends of the fuel channel 3 are fuel inlet 4 and fuel outlet 5 respectively, and a plurality of horizontally arranged injection holes 10 are arranged on the axis, when the axis moves left and right ...

Embodiment 2

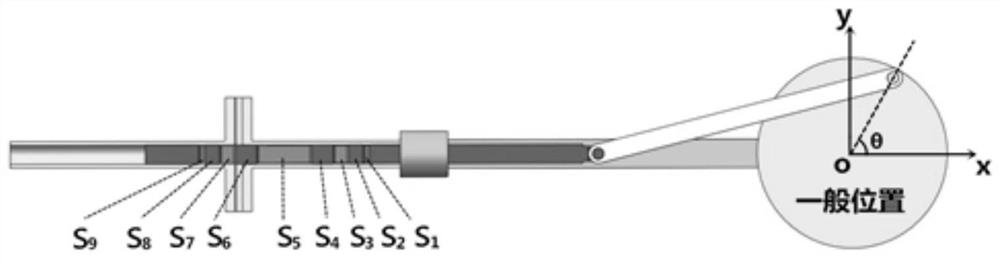

[0050] In this embodiment, the pulse frequency is 400 Hz, the motor speed is 50 revolutions per second, and the spray holes are five square holes, the width of the square holes is equal to the diameter of the fuel inlet, and the spray holes are distributed on the central axis in the x direction within a range of L=90mm, where L=2R, R is the radius of the driven turntable, calculate the length S of the first square hole 1 =3.59mm, length S of the second square hole 3 =8.33mm, the length of the third square hole S 5 =28.96mm, length S of the fourth square hole 7 =8.33mm and the fifth square hole length S 9 =3.59mm; the distance between the square holes satisfies the relational formula: the distance between the first and second holes is S 2 =7.42mm, the distance between the second and third holes is S 4 =11.18mm, the distance between the third and fourth is S 4 =11.18mm, the distance between the fourth and fifth is S 8 =7.42mm.

[0051] The above dimensions are calculated ...

Embodiment 3

[0061] This embodiment provides a method for fuel pulse injection under the condition of hypersonic incoming flow. Using the pulse injection device, the driven turntable rotates under the drive of the motor, and the transmission connecting rod drives the axis to make a straight line inside the lateral main body shell. Reciprocating movement, there is a fuel channel inside the longitudinal main body shell, the two ends of the fuel channel are fuel inlet and fuel outlet respectively, and a plurality of horizontally arranged injection holes are arranged on the axis, when the axis moves left and right to a certain position on it When the front edge of the injection hole and the fuel passage begin to overlap, the fuel passage communicates, and the fuel enters from the fuel inlet and is sprayed out from the fuel outlet. Closed, a pulse process ends until the next injection hole coincides with the fuel channel; the axis moves back and forth continuously to form an on-off period interv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com