Turnover type high-voltage switch

A high-voltage switch and flip-type technology, which is applied in high-voltage/high-current switches, electric switches, high-voltage air circuit breakers, etc., can solve the problems that cannot realize multiple guarantees and automatic rebound functions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

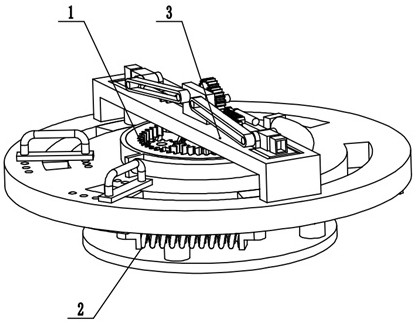

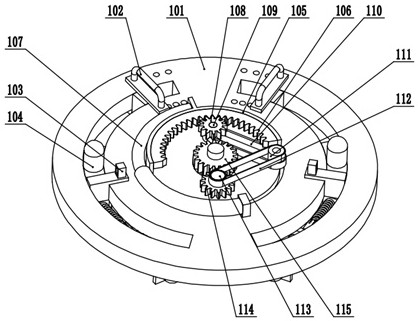

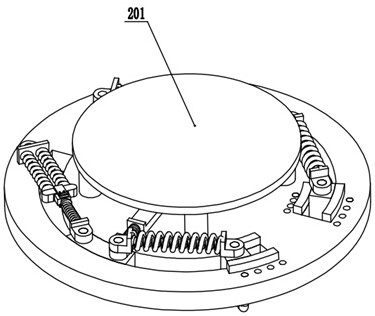

[0026] Example: such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 A flip-type high-voltage switch is shown. The rotating system 1 is a basic device, and the rotating system 1 is an installation platform for the rebound system 2 and the turning system 3 .

[0027] The rotating system 1 includes: a main plate 101, a U-shaped pin 102, an interface 103, a guide post 104, a gear ring seat 105, a half gear ring 106, an arc cylinder 107, an arc gear 108, an arc shaft 109, and an upper transmission belt 110, belt column 111, lower transmission belt 112, lower transmission shaft 113, lower gear 114, main gear 115, the U-shaped latch 102 is fixedly installed on the main disk 101, and the interface one 103 is fixedly installed on the movable arc block 213, The guide post 104 is fixedly installed on the movable arc block 213, the movable arc block 213 is slidably installed on the main disk 101, the half gear ring 106 is fixedly installed on the gear ring se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com