Motor shaft clamping tool, circumferential correction device and keyway symmetry degree detection tool

A technology for clamping tooling and motor shafts, which is applied in the field of circumferential correction devices, keyway symmetry inspection tools, and motor shaft clamping tooling, and can solve problems that affect the accuracy of detection, affect detection results, and consume time and effort.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

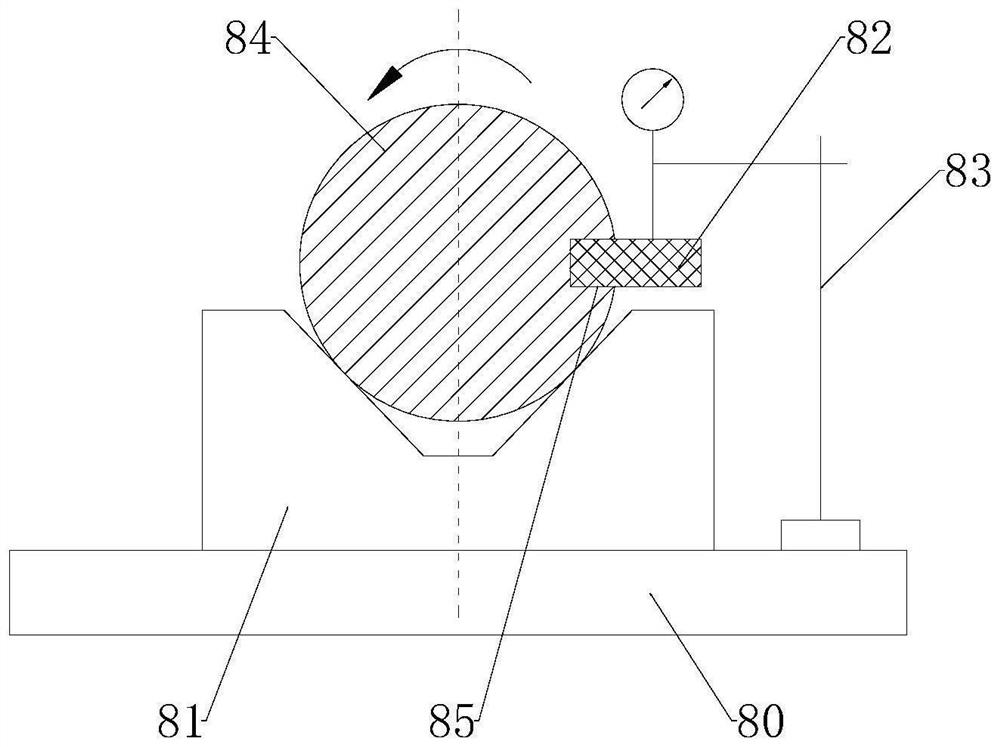

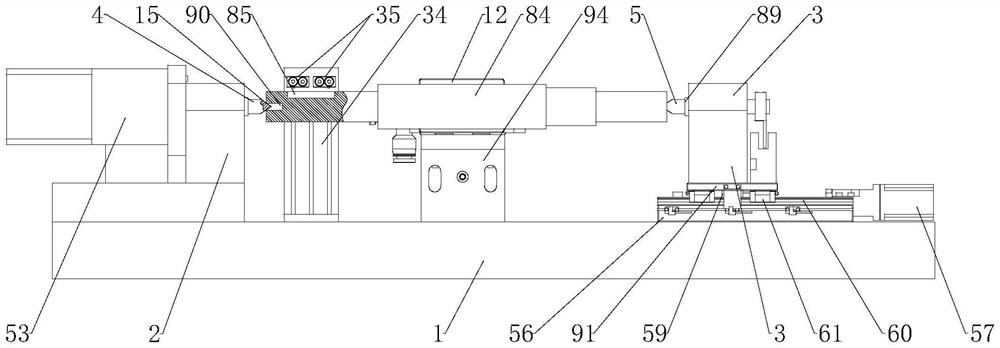

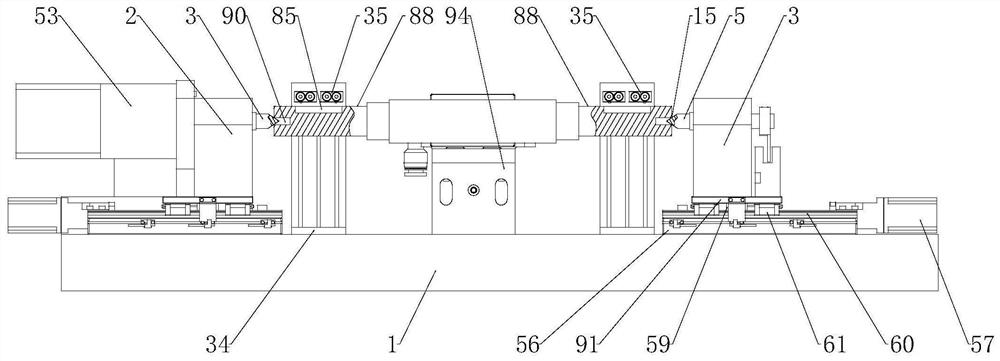

[0088] like Figure 2 to Figure 7 As shown, a motor shaft clamping tooling includes a lower bearing base 1;

[0089] A front fixed seat 2 and a rear seat driving device are installed on the lower bearing base 1, the output end of the rear seat driving device is connected with a rear movable seat 3, and the rear seat driving device acts on the rear movable seat 3, so that: the rear movable seat 3 can be relatively The front fixed seat 2 moves forward and backward;

[0090] The front fixed seat 2 is rotatably connected with the active thimble 4, and the rear movable seat 3 is rotatably connected with the driven thimble 5 facing the active thimble 4. Circumferential correction driving device;

[0091] The lower bearing base 1 is also equipped with two clamping drive devices symmetrically arranged left and right, the output end of the clamping drive device is connected with the clamping assembly, and the clamping drive device acts on the clamping assembly, so that: the clamping ...

Embodiment 2

[0103] like Figure 2 to Figure 12 As shown, a motor shaft circumferential correction device includes a motor shaft clamping tool as described in any one of Embodiment 1;

[0104] An upper bearing frame 16 is also arranged on the lower bearing base 1;

[0105] Correction support frame 17 is installed on the upper bearing frame 16, correction drive device 18 is installed on the correction support frame 17, the output end of correction drive device 18 is connected with image acquisition assembly, correction drive device 18 acts on image acquisition assembly, makes: image The collection assembly can move relative to the upper carrier 16;

[0106] The image acquisition assembly includes an image acquisition connection frame 78, and the image acquisition connection frame 78 is provided with an image acquisition device 19 and a coaxial light source 20 matched with the image acquisition device 19;

[0107] A fixed installation frame 21 is also installed on the upper carrier 16, and...

Embodiment 3

[0111] like Figure 2 to Figure 19 As shown, a motor shaft keyway symmetry inspection tool includes a motor shaft circumferential correction device as described in any one of Embodiment 2;

[0112] A movable support plate 26 that can rotate relative to the upper support frame 16 is installed on the upper carrier frame 16, and a support plate drive device for driving the movable support plate 26 to rotate is also installed on the upper carrier frame 16;

[0113] The bottom end of the movable support plate 26 is equipped with the correction support frame 17 and the positioning support frame 27 which is misplaced with the correction support frame 17, the positioning support frame 27 is equipped with a positioning up and down driving device 28, and the output end of the positioning up and down driving device 28 The positioning block assembly is connected, and the positioning up and down driving device 28 acts on the positioning block assembly, so that: the positioning block assemb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com