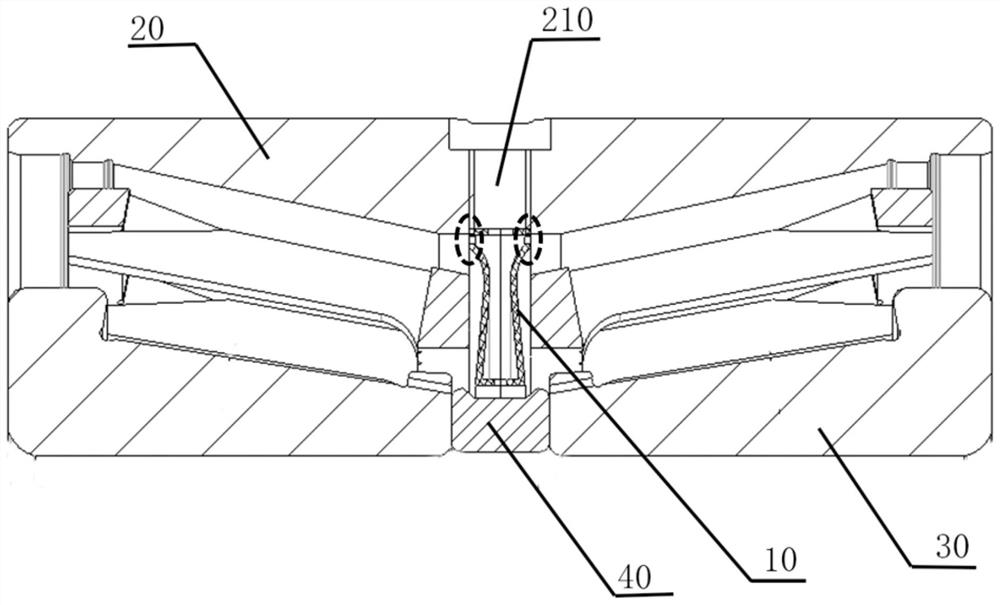

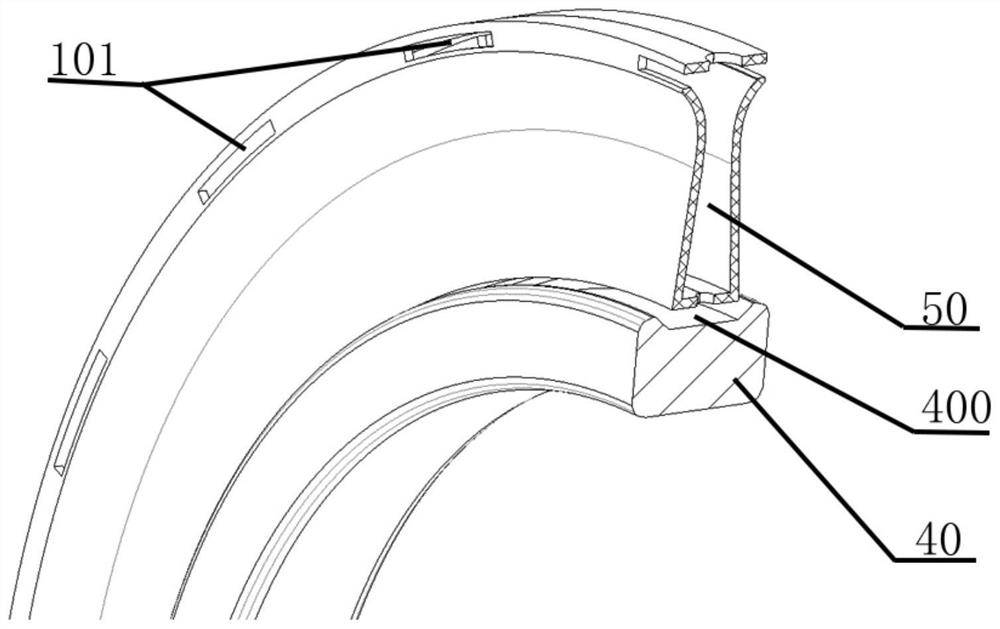

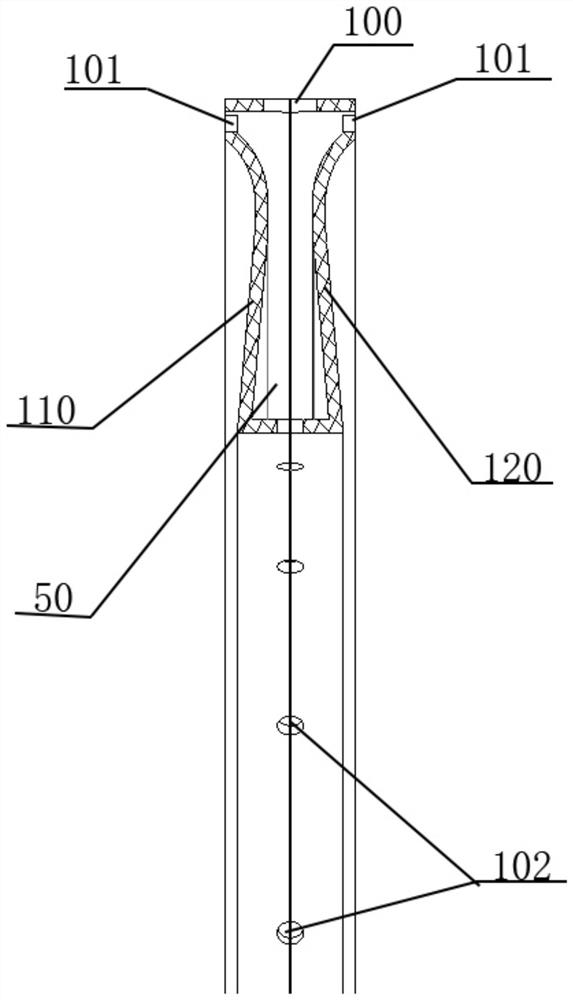

Tapered roller bearing and grease collecting device

A tapered roller bearing and grease collection technology, applied in the mechanical field, can solve the problems affecting the bearing life and high temperature at the position of the spacer ring, and achieve the effects of prolonging the service life, simple installation and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] It can be seen from the background art that the service life of the current tapered roller bearing is not good.

[0030] In order to prolong the service life of the tapered roller bearing, an embodiment of the present invention provides a grease collecting device and a tapered roller bearing, by fixing the grease collecting device on one of the bearing outer ring and the spacer ring, and the There is a gap between the grease collecting device and the other of the bearing outer ring and the intermediate ring, and the grease collecting device is provided with an oil outlet hole penetrating through the housing of the grease collecting device. Because the grease collecting device is installed between the bearing outer ring and the intermediate ring, by storing the grease at the position of the intermediate ring in the hollow oil storage chamber, when the bearing is running at high speed, the grease in the grease collecting device can pass through the oil outlet hole Slowly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com