Loading system for mechanical simulation test

A loading system and simulation test technology, applied in the application of repetitive force/pulse force to test the strength of materials, the application of stable tension/pressure to test the strength of materials, scientific instruments, etc. Fix difficulties etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

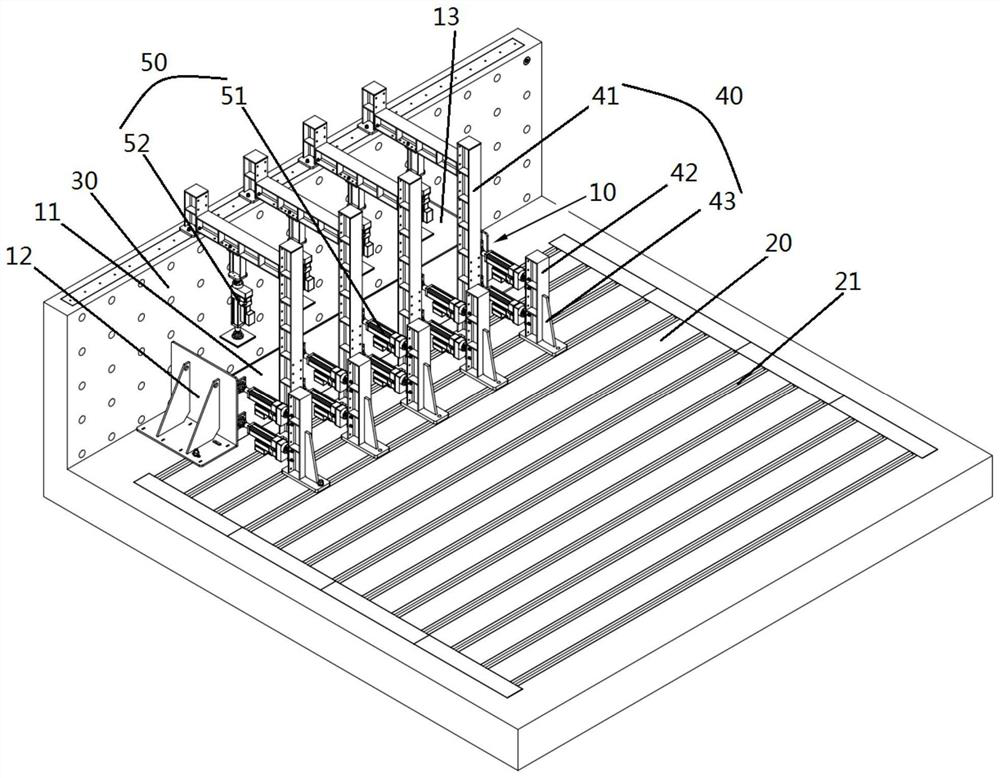

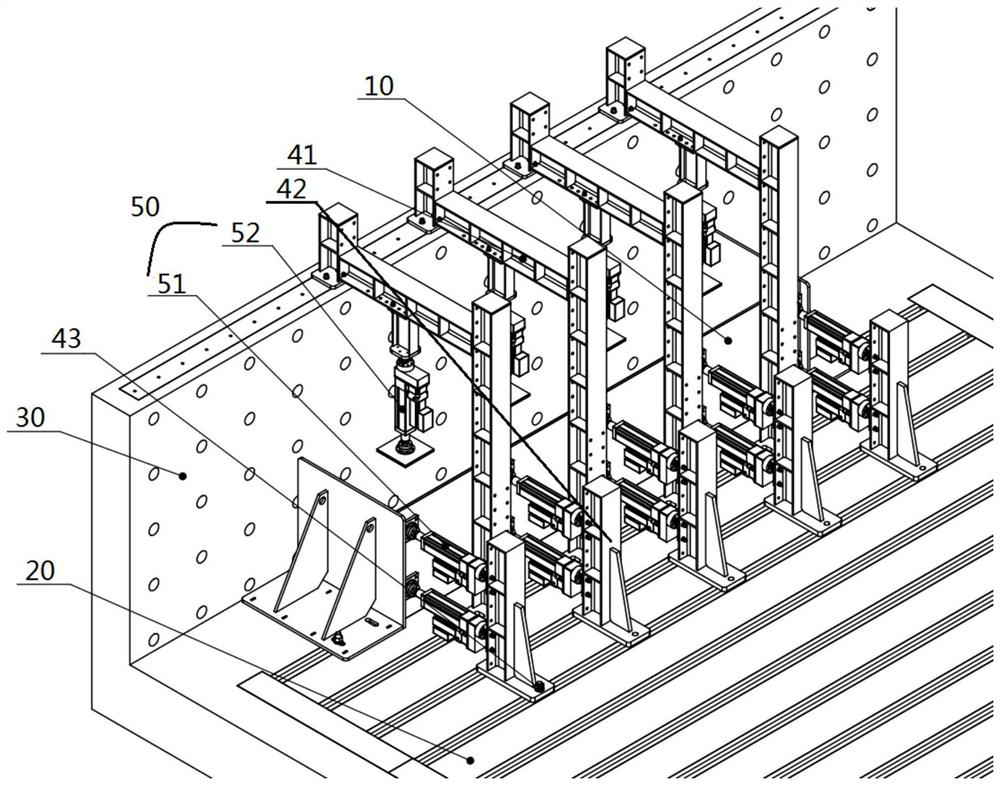

[0046] Figure 1-7 , 9-11 show the loading system used in the mechanical simulation test in this embodiment. Such as figure 1 As shown, the loading system of this embodiment includes: a test container 10 , a reaction force pedestal 20 , a reaction force wall 30 , a reaction force frame 40 and an actuator 50 .

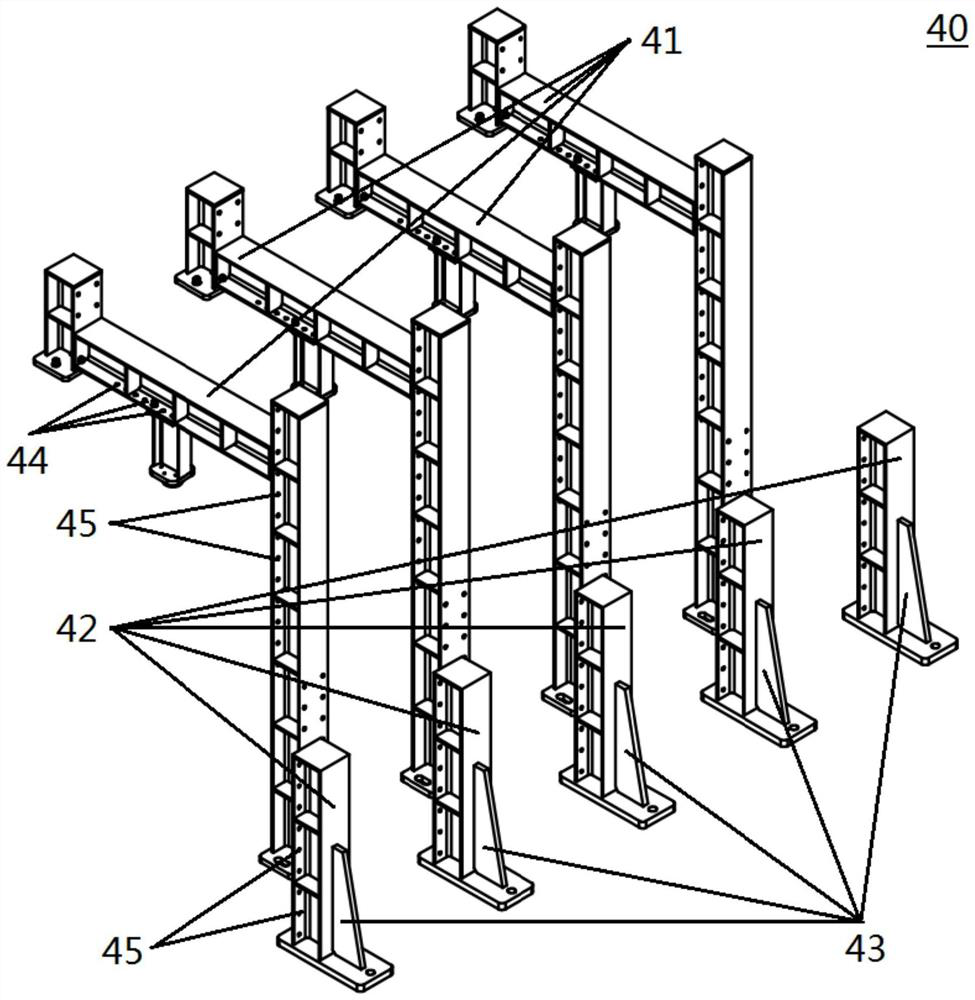

[0047] The reaction force wall 30 is vertically arranged on the reaction force pedestal 20, and a plurality of reaction force frames 40 are arranged on the reaction force pedestal 20 in a longitudinal array, such as Figure 1-3 shown. The test container 10 is arranged on the counter force pedestal 20 and abuts against the counter force wall 30 , and is used for accommodating test filling materials, such as various test models, various soil bodies, other filling materials and the like. The actuator 50 includes a horizontal actuator 51 and / or a vertical actuator 52 arranged on the reaction force frame 40; the horizontal actuator 51 is perpendicular to the reaction forc...

Embodiment 2

[0066] The loading system of this embodiment is basically the same as the loading system of Embodiment 1, the main difference is that: the test container 10 also includes: a cover plate arranged above the first pressure plate 11, the front pressure plate baffle 12 and the rear pressure baffle 13 14, such as Figure 8 As shown, the cover plate 14 is perpendicular to the reaction wall 30 and is used to seal the accommodating space. The use of the cover plate 14 can prevent the leakage of the tested filling due to the softness of the tested filling during the simulation test, and improve the effect of the simulation test.

Embodiment 3

[0068] The loading system of this embodiment is basically the same as that of the first or second embodiment, the main difference being that the structure of the test container 10 is different.

[0069] Such as Figure 12-20 As shown, in the present embodiment, the test container 10 includes: a rectangular frame 15, at least a second pressure plate 16 arranged on the front side, rear side and right side of the rectangular frame 15, and a test pile 17; the second pressure plate 16 An accommodating space for accommodating the filler to be tested is formed between the reaction wall 30 ; the test pile 17 is arranged in the accommodating space, and the actuator 50 abuts against the test pile 17 . The second pressure plate 16 can be made of aluminum alloy plate to ensure a certain rigidity.

[0070] Optionally, in order to further improve the structural stability of the test container, a reinforcing plate 151 can be set in the rectangular frame 15, see Figure 12 , 14 and 15. In...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap