Boiling-type sterilizer

A sterilizer and temperature sensor technology, applied in disinfection, sanitary equipment for toilets, buildings, etc., can solve the problems of scalded staff, easily scalded staff, inconvenient equipment access, etc., to avoid overheating and scald, disinfection effect Good and easy to take effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

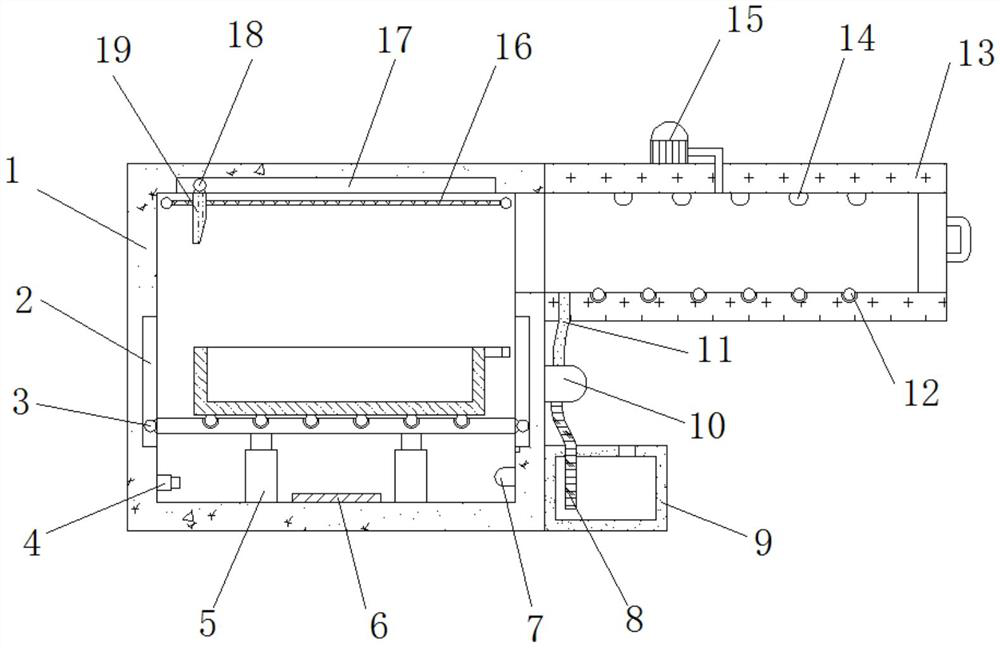

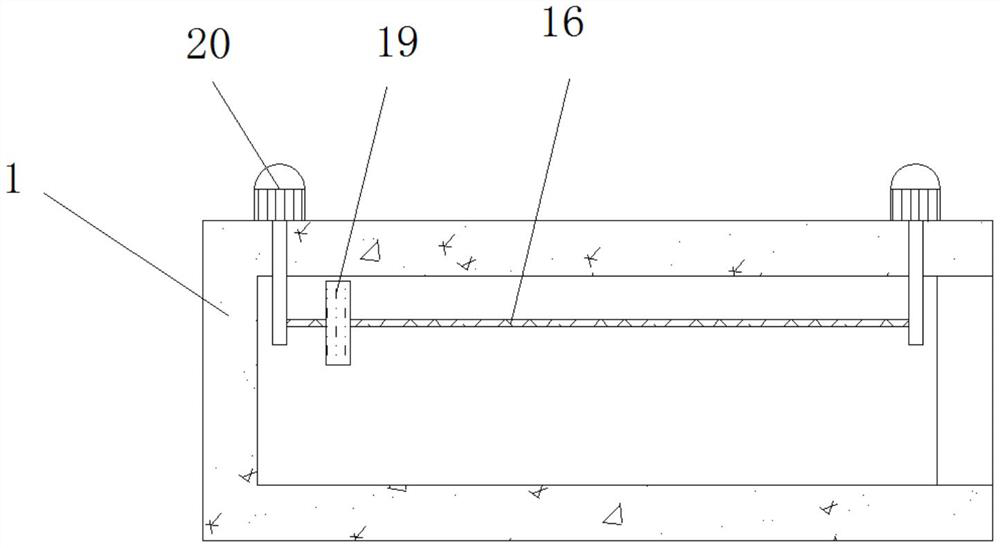

[0022] refer to Figure 1-3 , a boiling type sterilizer, comprising a housing 1, a second chute 17 is opened in the middle of the top inner wall of the housing 1, and a second pulley 18 is slidably connected to the inside of the second chute 17, and the second pulley 18 is away from One end of the second chute 17 is connected with a movable block 19 by a fastening bolt, and both sides of the movable block 19 are connected with a winding rope 16 by a fastening bolt, and both sides of the outer wall of one end of the housing 1 are connected by a fastening bolt. There is a winding motor 20, and the ends of the two winding ropes 16 away from the movable block 19 are respectively connected with the output shafts of the two winding motors 20 by fastening bolts.

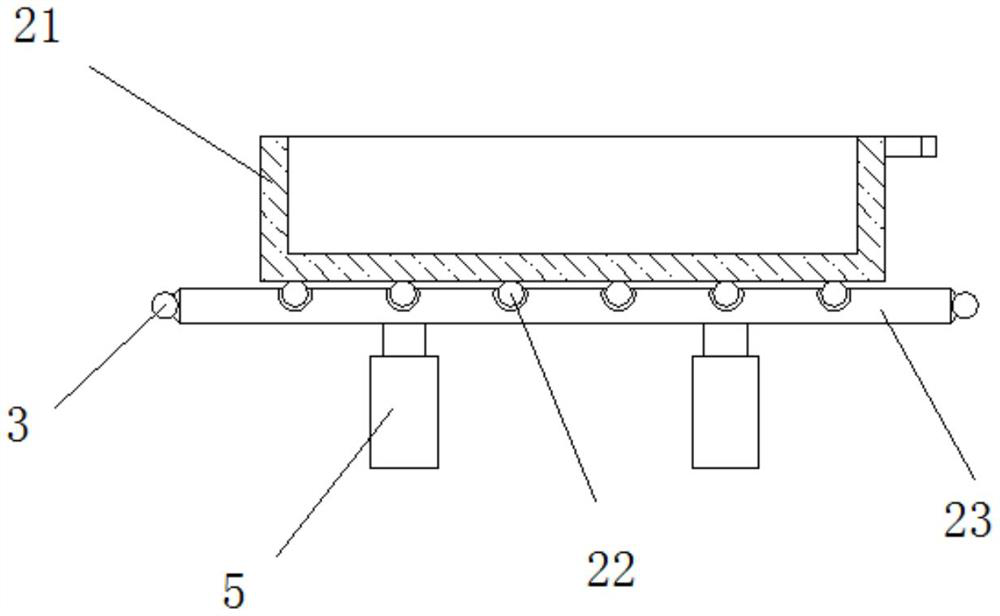

[0023] The bottoms of the inner walls on both sides of the casing 1 are provided with first sliding grooves 2 , and the insides of the two first sliding grooves 2 are slidingly connected with first pulleys 3 . Both sides o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com