An anti-oxidation treatment device for the surface of a square box

A processing device and anti-oxidation technology, applied in the field of auto parts, can solve the problems of waste of resources, poor environmental protection, and low work efficiency, and achieve the effects of preventing waste of resources, ensuring quality, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

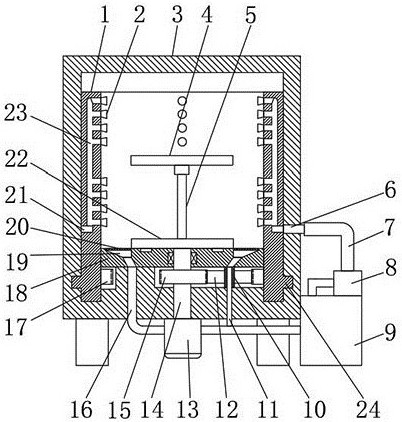

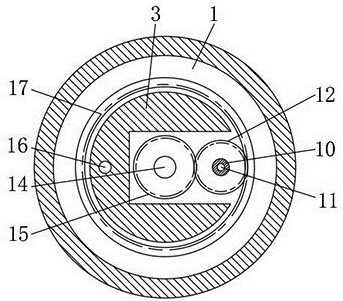

[0026] Embodiment one: refer to Figure 1~4 , in an embodiment of the present invention, a square box surface anti-oxidation treatment device includes an outer box body 3, and a motor 13 is provided at the outer bottom of the outer box body 3 to provide a power source. The output of the motor 13 is connected to a main shaft 14, and the main shaft 14 is the most The upper end is fixedly connected with the lower seat 22, and the middle part of the upper end of the lower seat 22 is fixedly connected with the support column 5, and the upper end of the support column 5 is threadedly connected with the upper seat 4, so as to realize multi-position placement, so that multiple square box parts can be simultaneously protected against oxidation. processing, to improve processing efficiency, a driving gear 15 is arranged on the main shaft 14 running through the inside of the outer box 3, the driving gear 15 is meshed with a driven gear 12, and the driven gear 12 is meshed with a gear ring...

Embodiment 2

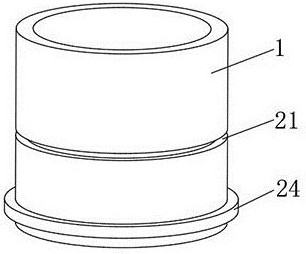

[0035] Embodiment 2: This invention also provides another embodiment, which is improved on the basis of the above embodiment. The side end of the inner cylinder 1 is provided with a locking block 24, and the locking block 24 moves It is connected to the inner wall of the outer box body 3 to achieve stable restraint on the inner cylinder 1 .

[0036] In summary, when the invention works, the after-treatment components of the square box that need to be sprayed with anti-oxidation paint on the outer surface are placed on the upper seat 4 and the lower seat 22, the motor 13 and the water pump 8 are started, and the main shaft 14 drives The upper seat 4 and the lower seat 22 rotate in the same direction at a constant speed, and at the same time the main shaft 14 is driven by the driving gear 15, the driven gear 12, and the gear ring 17 to realize the uniform rotation of the inner cylinder 1 relative to the main shaft 14, that is, the inner cylinder 1 and the square box. The relativ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com