Deburring and chamfering tool

A chamfering tool and deburring technology, which is applied in the direction of manufacturing tools, metal processing equipment, milling machine equipment details, etc., can solve problems such as injuries, burrs, and failure to perform functions, and achieve the effect of uniform processing surface and less load change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

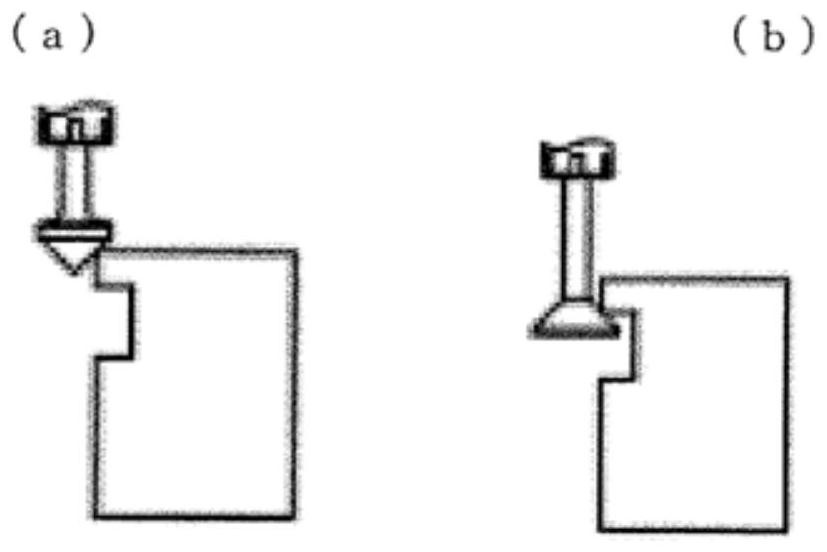

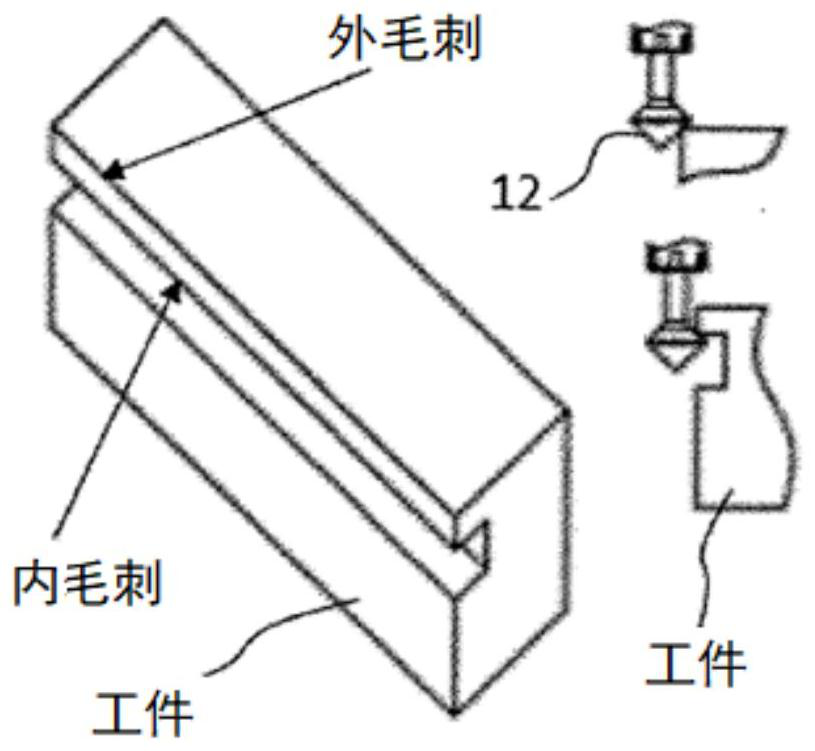

[0026] The roughness of the burr of the cast product is not uniform, and it is difficult to create a program for machining. Therefore, the deburring tool needs to have a telescopic mechanism that has flexibility for unevenness. With the telescopic mechanism, a safe and tidy processed surface can be obtained through a simple procedure.

[0027] Furthermore, from the viewpoint of ease of use, it is necessary that the load change due to expansion and contraction of the expansion and contraction mechanism be small.

[0028] The deburring and chamfering tool related to the present invention will be described in detail below with reference to the accompanying drawings.

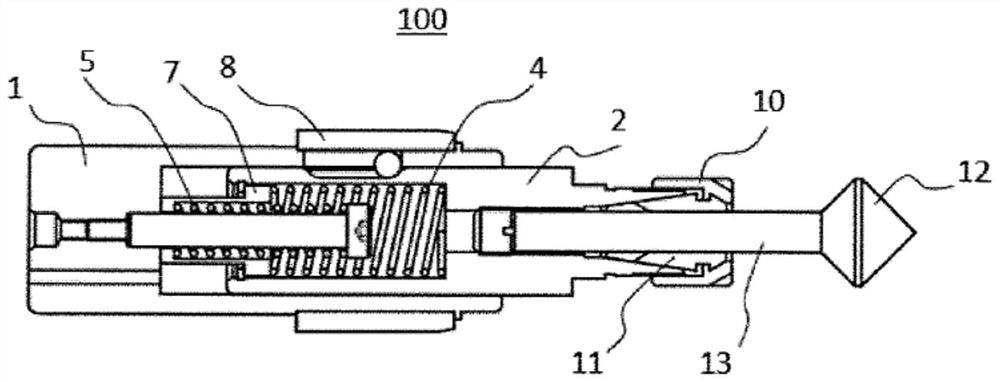

[0029] figure 1 is a sectional view showing the structure of the deburring and chamfering tool 100 according to the present invention. The deburring and chamfering tool 100 consists of a main body 2, a long handle 1 as a connecting device with a drive motor and a tool holder installed on the left side of the main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com