Novel mechatronical low load oil pumping machine

A low-load, pumping unit technology, applied in the direction of production fluid, wellbore/well components, earthwork drilling and production, etc., can solve the problem that the gear of the reducer is vulnerable to "backward impact, increase the working load of the motor and reducer, shorten the deceleration To solve problems such as the service life of the device, to achieve the effect of operation balance, energy consumption reduction, and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Embodiments of the present invention will be specifically described below in conjunction with the accompanying drawings.

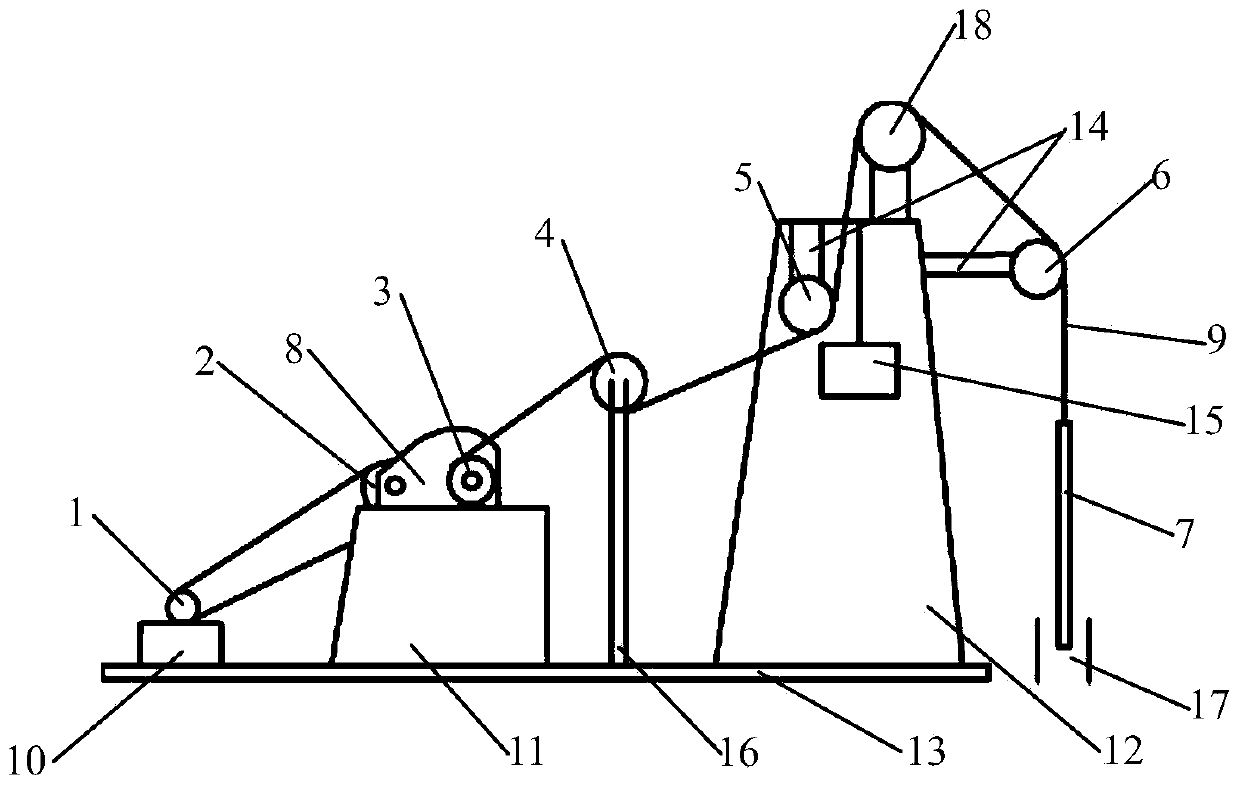

[0014] Such as figure 1 As shown, the present invention provides a novel mechatronic low-load pumping unit, which comprises a motor 1, a pulley 2, a driving pulley 3, a driven pulley 4, a first guide pulley 5, a second guide pulley 6, a pumping pulley Oil rod 7, fixed pulley 18, motor 1 is positioned on base one 10, and the rotating shaft of motor 1 is connected with pulley 2, and pulley 2, driving pulley 3 are connected with reduction motor 81 respectively, and pulley 2, driving pulley 3 are positioned at the reduction motor 81 respectively. At both ends, the reduction motor 81 is located on the base 2 11, the driving wheel 3 and the driven wheel 4 are connected by a rope 9, and the driven wheel 4 is connected to the first guide wheel 5 by a rope 9, and the first guide wheel 5 is used to maintain the position on the first guide wheel. In the direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com