Fast-assembly guide rail buffer

A guide rail cushioning and quick installation technology, which is applied to furniture parts, household appliances, drawers, etc., can solve the problem that the guide rail buffer installation process is not fast enough

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

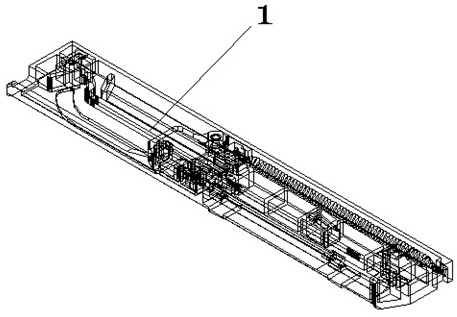

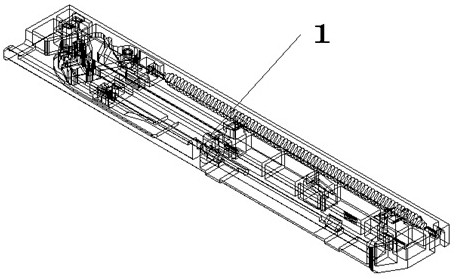

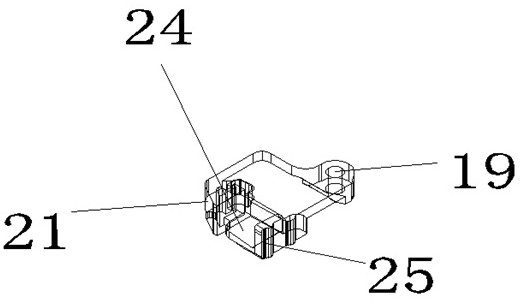

[0029] A quick-install guide rail buffer, including two left and right symmetrically arranged mechanisms 34, the mechanism 34 is composed of a spring frame 1, two sliders 2, slider connectors 3, pressing buffer unloading oil pipe 4 and tension spring 5, the slider A first U-shaped hanging groove 29 and a second U-shaped hanging groove 30 are provided in the connecting piece 3, and a circular guide column 28 is arranged in the slider connecting piece 3, and the press buffer unloading oil pipe 4 and the slider connecting piece 3 pass through the first U-shaped hanging groove. U-shaped hanging groove 29 is connected with the second U-shaped hanging groove 30, and the two sliders 2 are connected with the circular guide column 28 in the slider connector 3 through the inner round through hole, and the two sliders 2 and the pressing buffer unloading oil pipe 4 Installed on the spring frame 1, the tension spring 5 is installed on the slider connector 3 and the spring frame 1, and the b...

Embodiment 2

[0031]A quick-install guide rail buffer, including two left and right symmetrically arranged mechanisms 34, the mechanism 34 is composed of a spring frame 1, two sliders 2, slider connectors 3, pressing buffer unloading oil pipe 4 and tension spring 5, the slider A first U-shaped hanging groove 29 and a second U-shaped hanging groove 30 are provided in the connecting piece 3, and a circular guide column 28 is arranged in the slider connecting piece 3, and the press buffer unloading oil pipe 4 and the slider connecting piece 3 pass through the first U-shaped hanging groove. U-shaped hanging groove 29 is connected with the second U-shaped hanging groove 30, and the two sliders 2 are connected with the circular guide column 28 in the slider connector 3 through the inner round through hole, and the two sliders 2 and the pressing buffer unloading oil pipe 4 Installed on the spring frame 1, the tension spring 5 is installed on the slider connector 3 and the spring frame 1, and the bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com