Multipurpose spraying device

A spraying device and multi-purpose technology, applied in the direction of spraying device, etc., can solve the problems of inability to guarantee the efficiency and stability of painting and spraying, inability to guarantee the quality of spraying, and waste of paint.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

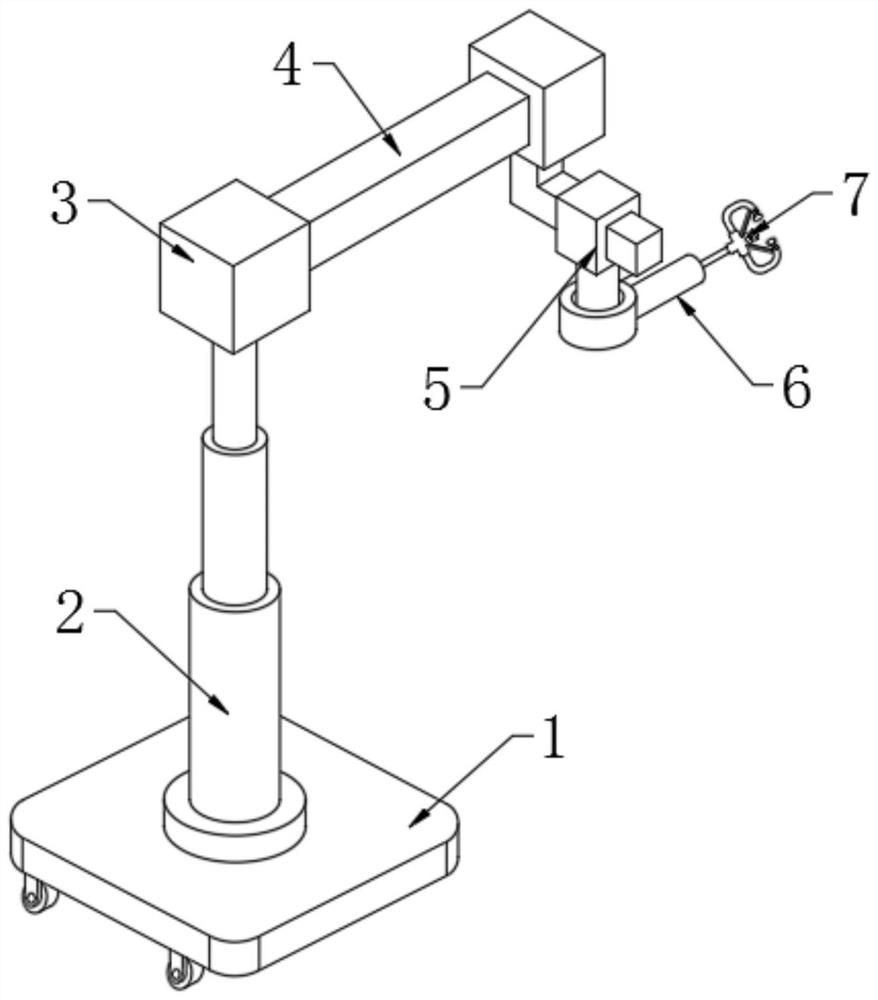

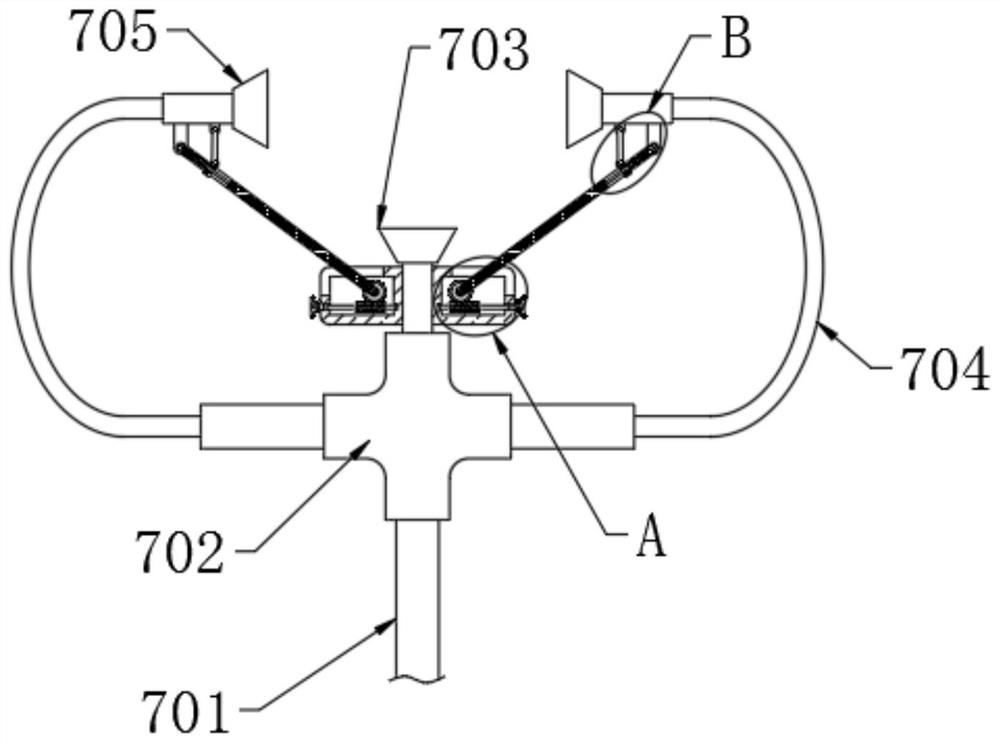

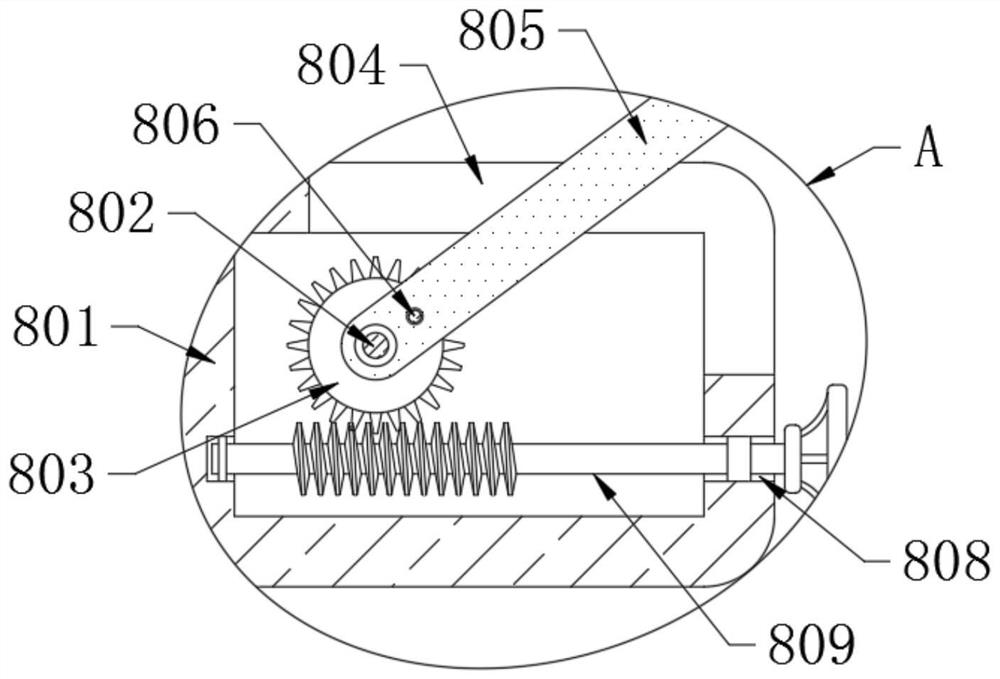

[0026] refer to Figure 1-5 , a multi-purpose spraying device is proposed in this embodiment, comprising a base 1, a hydraulic rod 2 is fixedly installed on the top of the base 1, a mounting block 3 is fixedly mounted on the top of the hydraulic rod 2, and a mounting block 3 is fixedly mounted on one side of the mounting block 3 Cross bar 4, and the end of cross bar 4 away from mounting block 3 is fixedly installed with mounting frame 5, and one side of mounting frame 5 is fixedly mounted with fixed rod 6, and the end of fixed rod 6 away from mounting frame 5 is fixedly mounted with spray mechanism 7, spraying The mechanism 7 includes a first conduit 701, the end of the first conduit 701 away from the installation frame 5 is fixedly installed with a four-way joint 702, the end of the four-way joint 702 away from the first conduit 701 is fixedly installed with a first nozzle 703, and the end of the four-way joint 702 is fixedly installed with a first nozzle 703. A second condui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com