Auxiliary cutting jig on stainless steel bowl basket support

A stainless steel technology on a bracket, applied in the direction of support, manufacturing tools, clamping, etc., can solve the problems of time-consuming marking operations and low production efficiency of bowls and baskets, and achieve the effect of fast marking speed and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

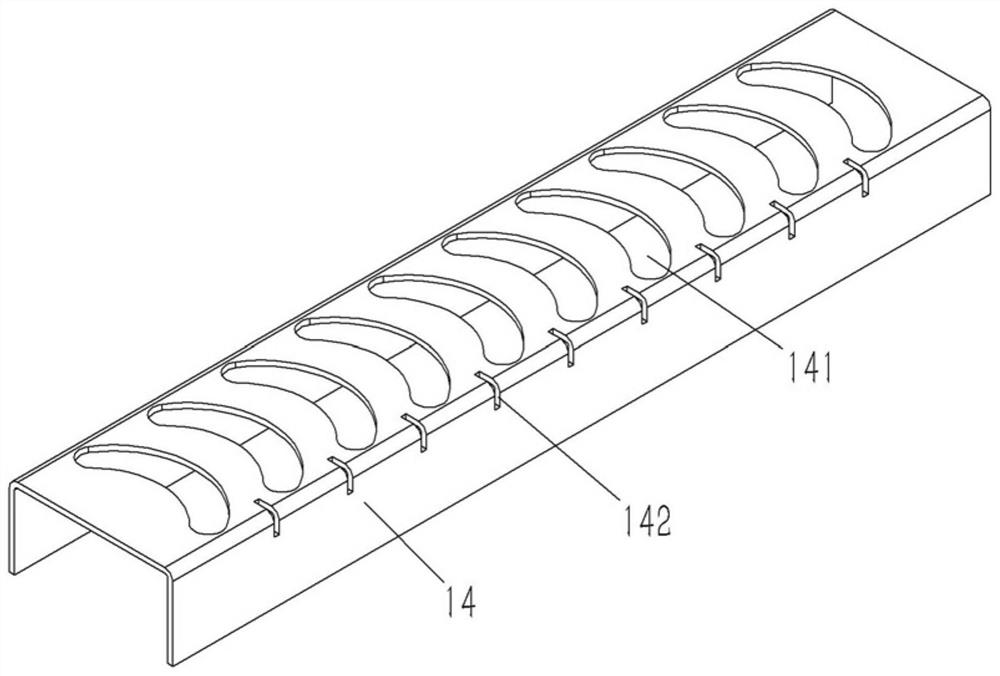

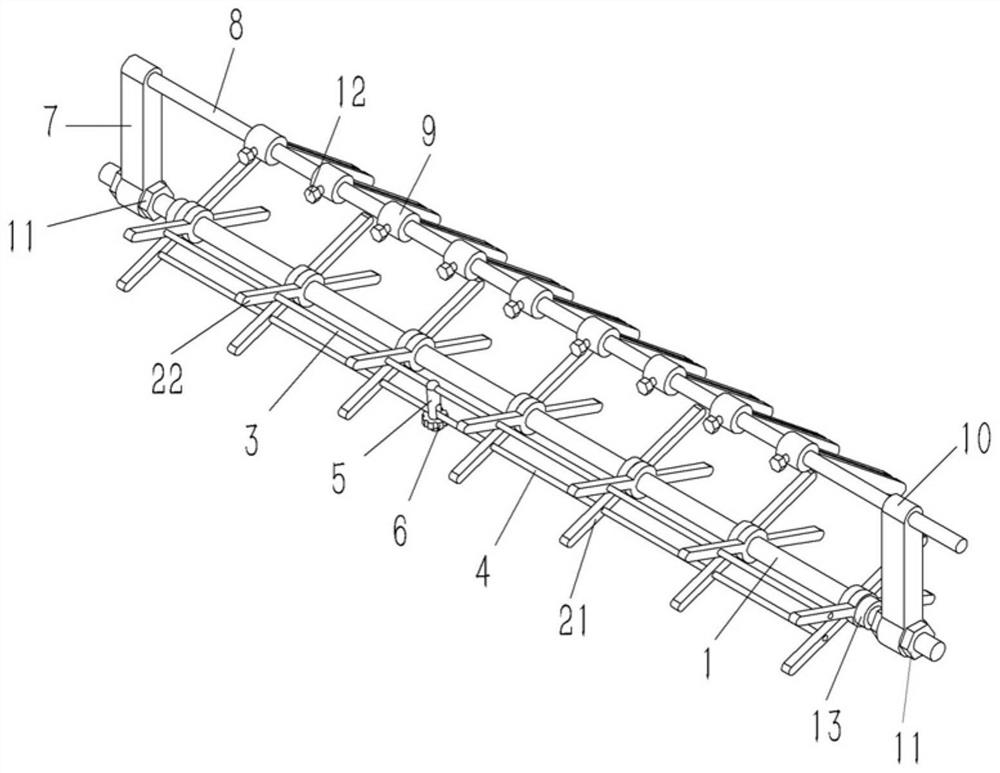

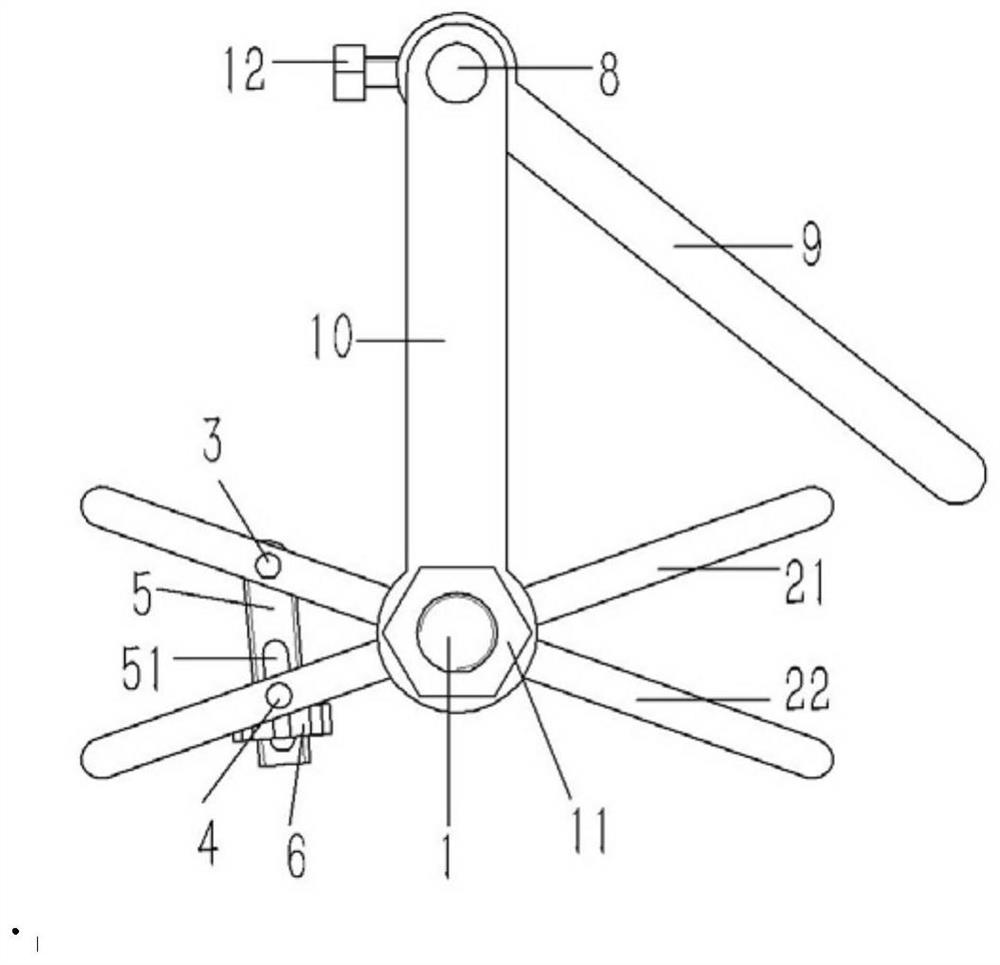

[0020] Example: see Figures 2 to 4 As shown, a cutting auxiliary jig on a stainless steel bowl basket bracket includes a horizontal axis 1, and several X-shaped support frames 2 are inserted on the horizontal axis 1, and the support frame 2 has two intersecting first support rods 21 and The second support rod 22, the middle part of the first support rod 21 is sleeved on the horizontal shaft 1, and the middle part of the second support rod 22 is fixed on the horizontal shaft 1 and abutted against the first support rod 21. The two support rods 22 and the first support rod 21 are respectively plugged and fixed with the first horizontal connecting shaft 3 and the second connecting shaft 4, and the other end of the screw rod 5 is sleeved on the first connecting shaft 3, and the other end is screwed. There is a lock nut 6, an adjustment groove 51 is formed on the screw rod 5, and the second coupling shaft 4 is inserted into the adjustment groove 51 of the screw rod 5;

[0021] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com