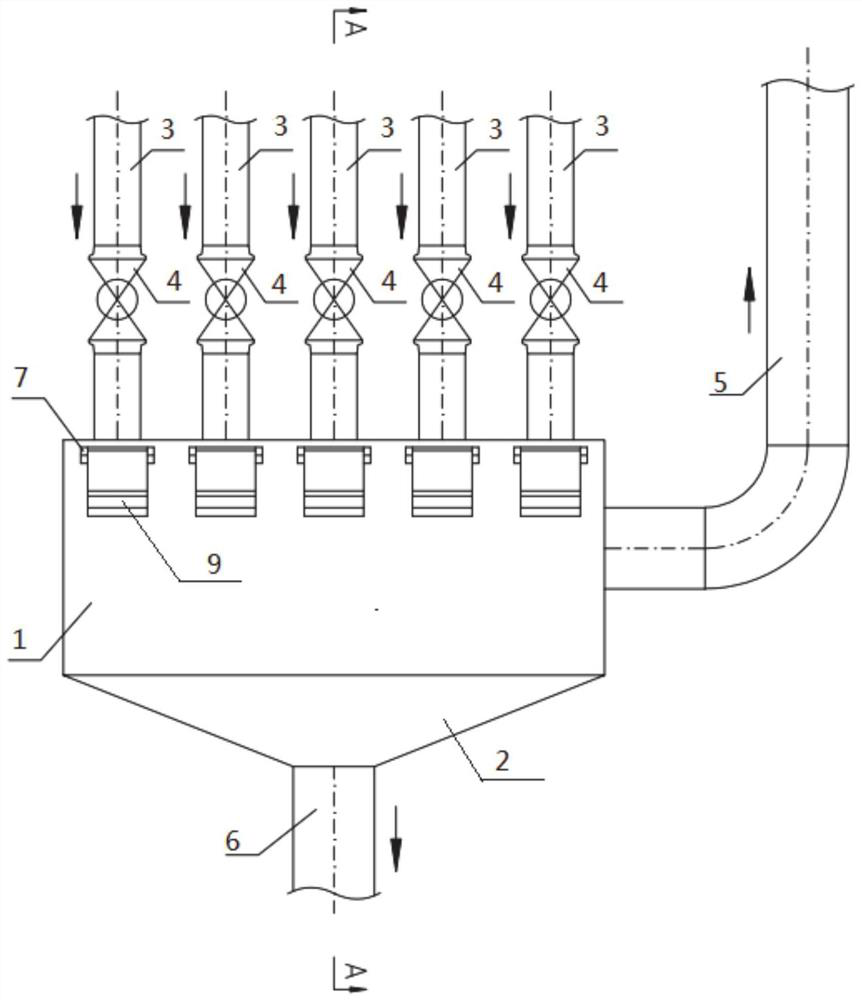

Anti-splashing centralized water and gas discharging funnel and method

A centralized, funnel technology, used in special distribution devices, containers, packaging, etc., can solve the problems of waste of working fluid, unsanitary workshop, hot water and steam splashing, etc., to avoid potential safety hazards, prevent splashing, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

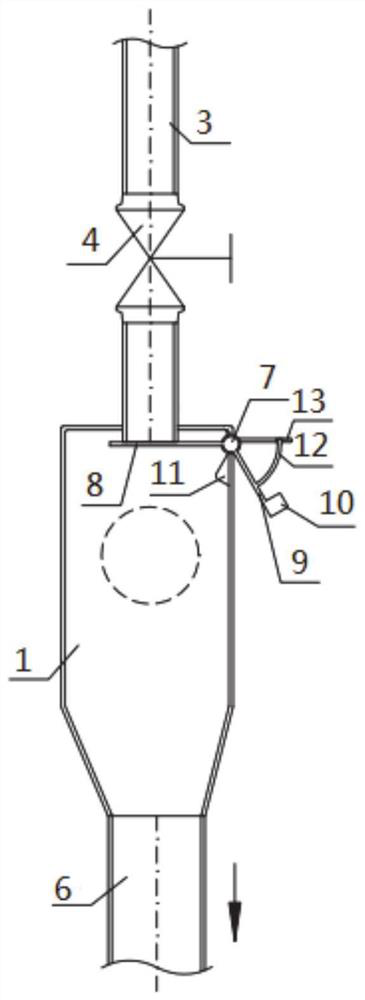

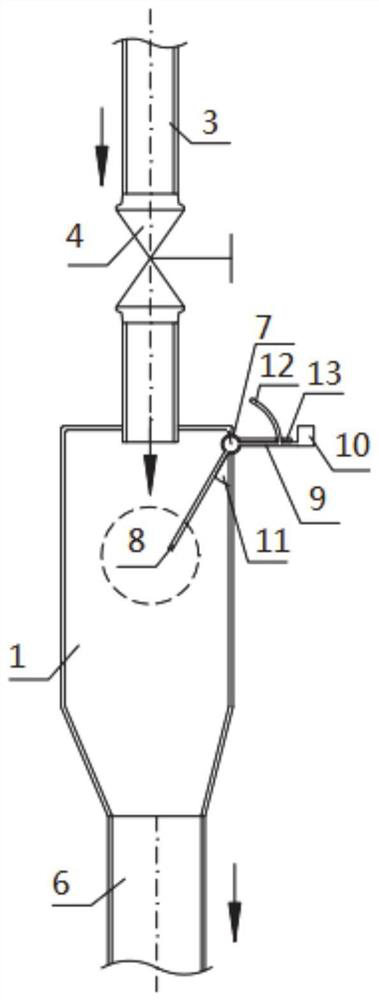

[0041]This embodiment discloses a working method of the splash-proof centralized water discharge and exhaust funnel described in Embodiment 1: the valve on the inlet pipe is opened, and the fluid in the inlet pipe flows into the funnel body. Due to the high pressure in the inlet pipe, the funnel The pressure inside the main body is small. Under the action of pressure difference, the fluid can push away the inner plate that covers the inlet pipe, causing the baffle to rotate, and under the action of the continuous impact force of the fluid, the inner plate can maintain a certain opening. At the same time, the outer plate drives the dial to move, the distance from the dial to the pointer through the through hole changes, and the current fluid flow is indicated by the scale line.

[0042] After the fluid enters the funnel body, it expands rapidly and lowers the pressure. The collected water is discharged into the non-pressurized jellyfish pipe connected to the drain pipe through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com