Mechanical transmission demonstration workbench

A technology of mechanical transmission and workbench, which is applied in the direction of educational appliances, instruments, teaching models, etc., can solve problems such as explaining, affecting the efficiency of classroom explaining, conflicts in using demonstration time, etc., to achieve easy understanding, increase explaining efficiency, and strong expandability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

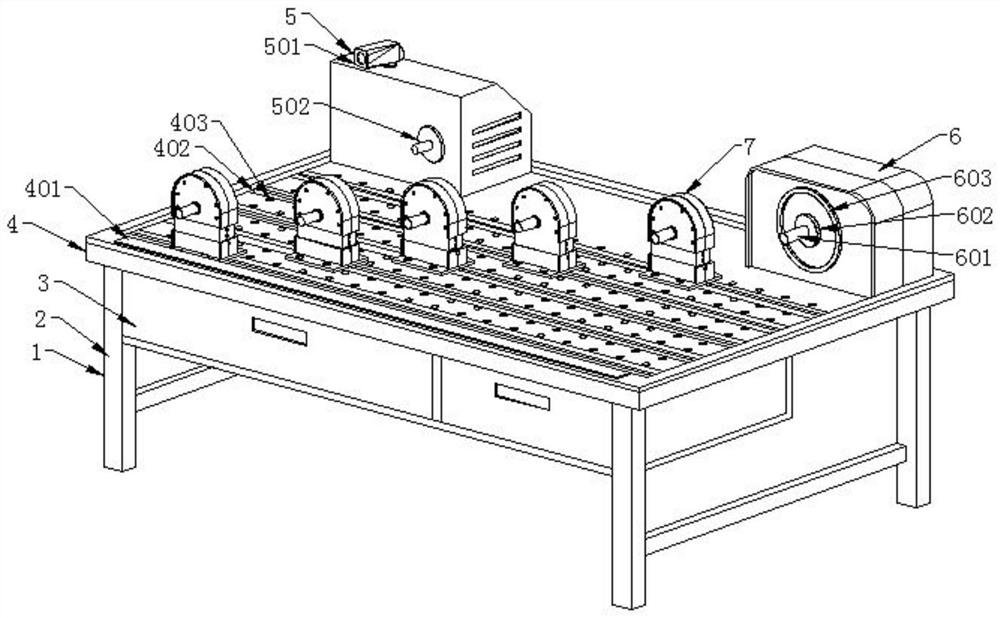

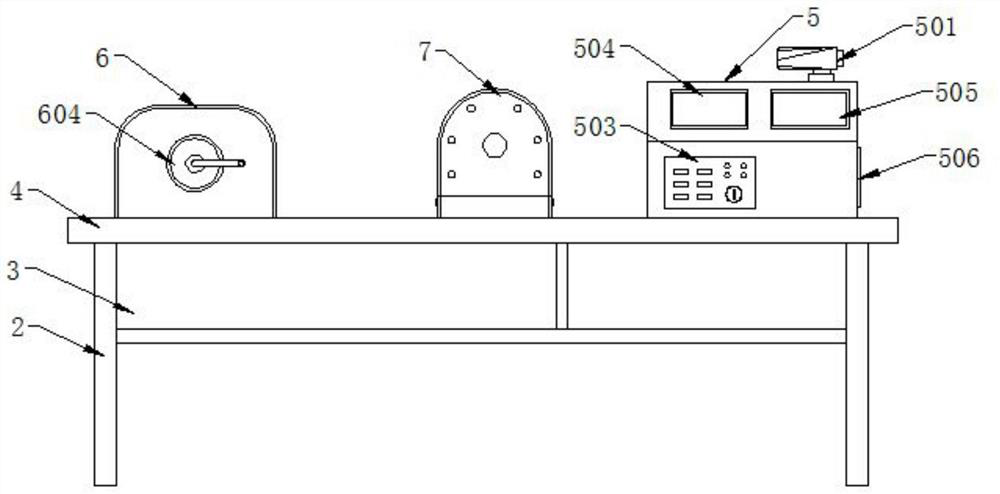

[0027] Such as Figure 1-5 As shown, the present invention provides a mechanical transmission demonstration workbench, including a workbench main body 1, a foot 2 is installed at the bottom of the workbench body 1, a drawer 3 is installed on the inside of the top of the foot 2, and a table is installed on the top surface of the foot 2. Plate 4, an electric control module 5 is installed on one side of the top surface of the table 4, a mechanical module 6 is installed on the other side of the top of the table 4, a scale 401 is installed on one end of the table 4, and the surface of the table 4 is provided with The slide rail 402 is provided with holes 403 at both ends of the slide rail 402 , and the main transmission member 7 is installed on the surface of the slide rail 402 .

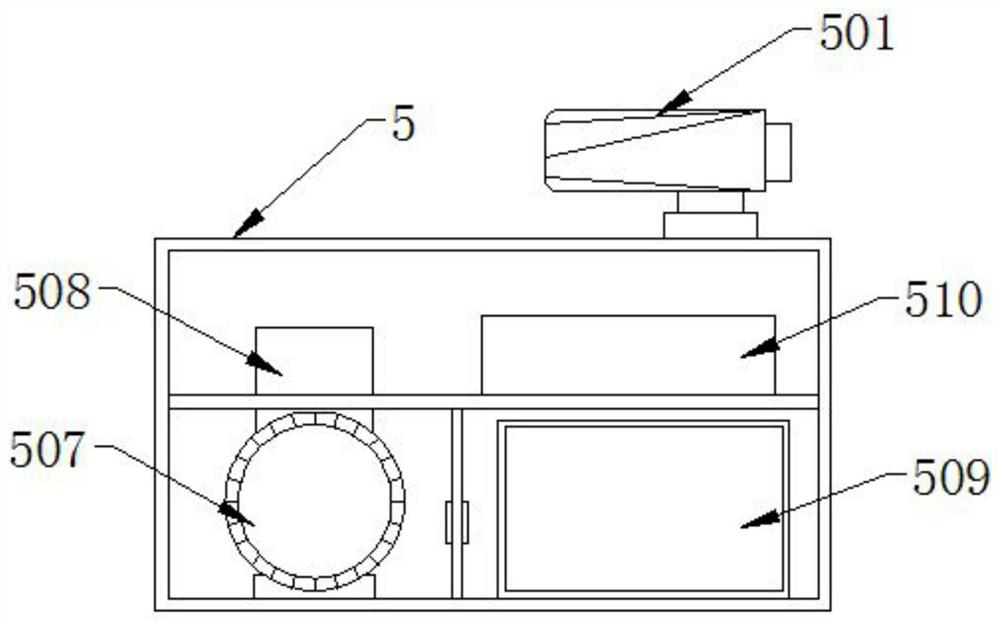

[0028] Further, a camera 501 is installed on one side of the top surface of the electronic control module 5, a first transmission shaft 502 is provided on one side surface of the electronic control modul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com