Casing device for reducing casing shear deformation and using method thereof

A casing device, shear deformation technology, applied in casing, drill pipe, earth-moving drilling and other directions, can solve the problem of not being able to run tools, and achieve the effect of reducing workload, convenient installation and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

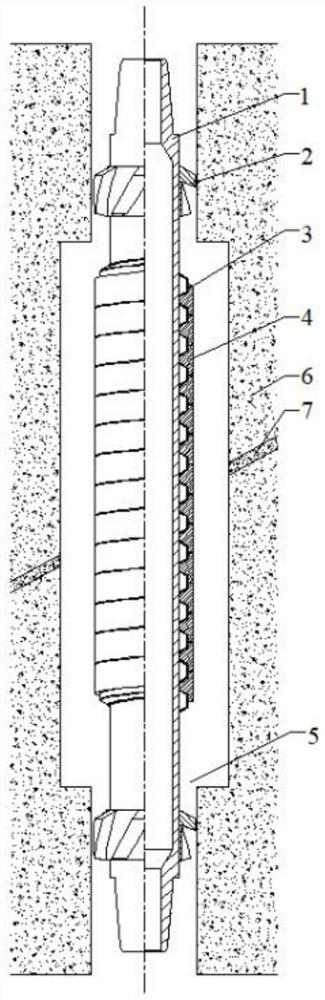

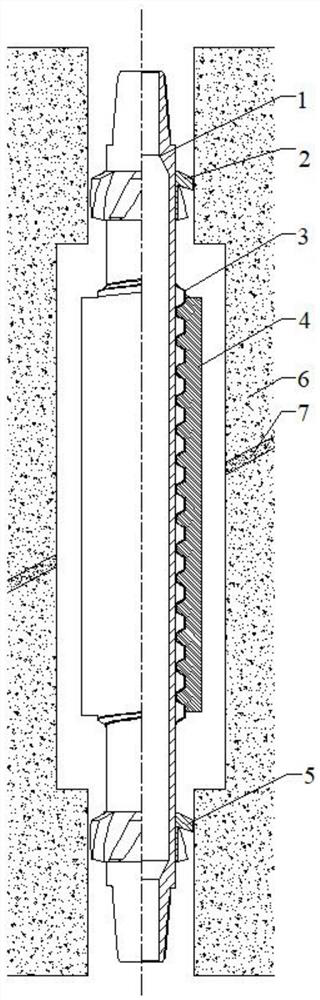

[0039] A casing device for reducing casing shear deformation and its use method, such as Figure 1-3 As shown, the casing device is set in the wellbore where the fracture zone 7 is located, and includes a casing 1, an upper centralizer 2 and a lower centralizer 5 arranged on the outer walls of both ends of the casing 1, and the casing 1 The outer wall is provided with a metal layer 3 , and the outer wall of the metal layer 3 is provided with a water-swellable rubber layer 4 .

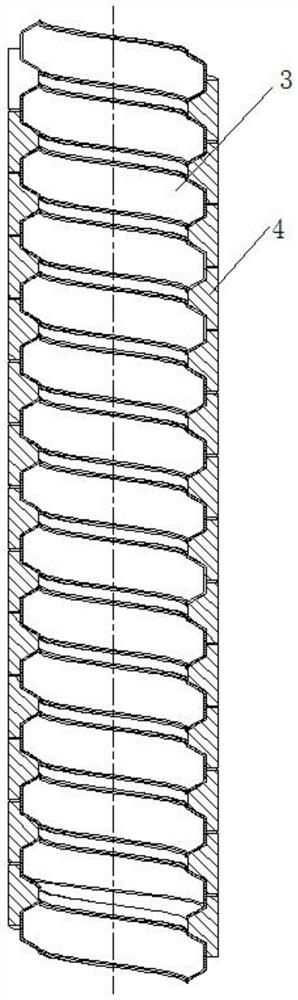

[0040] The inner wall of the water-swellable rubber layer 4 engages with the outer wall of the metal layer 3 and is fixed to the outer wall of the metal layer 3 by bonding; the outer wall of the metal layer 3 is in a spiral shape. The metal layer 3 is formed by spirally winding a metal strip with a convex cross-section on the outside of the sleeve 1 , and the water-swellable rubber layer 4 is formed by spirally winding the rubber strip meshed with the metal layer 3 on the outer layer of the metal layer ...

Embodiment 2

[0050] Based on Embodiment 1, between step 1) and step 2), the following steps are also included: reaming the wellbore at the location of the fracture zone 7, and the inner diameter of the wellbore after reaming ensures that a thicker cement sheath can be formed at this location ; The expanded outer diameter of the water-swellable rubber layer 4 is smaller than the inner diameter of the wellbore after reaming.

Embodiment 3

[0052] Such as Figure 4 As shown, the metal layer 3 and the water-swellable rubber layer 4 in this embodiment are bellows, and the rest of the structure and usage method are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com