A picking order control method and robot

A robot and order technology, applied in the field of robotics, can solve the problems of single picking and issuing strategy, heavy task burden, and heavy task burden of pickers, so as to shorten the execution path, improve the picking efficiency, and reduce the task burden.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

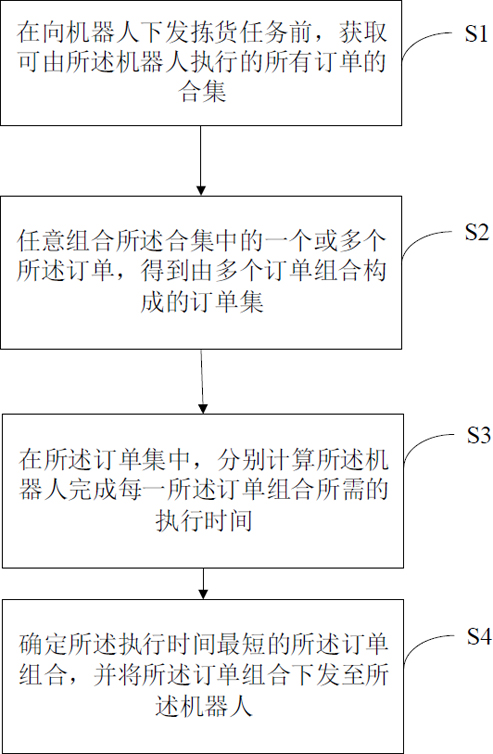

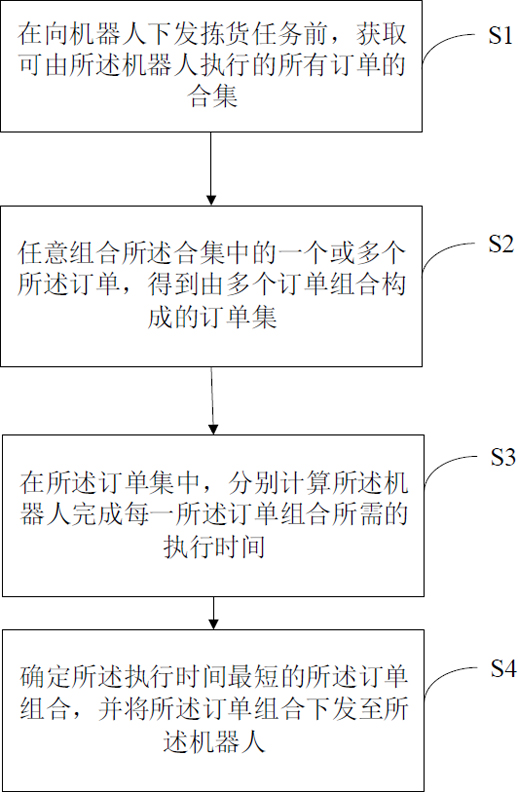

[0051] figure 1 It is a flow chart of the first embodiment of the picking order control method of the present invention. A method for controlling a picking order, the method comprising:

[0052] S1. Before sending the picking task to the robot, obtain a collection of all orders that can be executed by the robot;

[0053] S2. Arbitrarily combining one or more of the orders in the collection to obtain an order set composed of multiple order combinations;

[0054] S3. In the order set, calculate the execution time required by the robot to complete each order combination;

[0055] S4. Determine the order combination with the shortest execution time, and deliver the order combination to the robot.

[0056]In this embodiment, firstly, before sending the picking task to the robot, obtain a collection of all orders that can be executed by the robot, where, considering that in the prior art, the tasks sent to the robot are relatively random, it is impossible to The current task of ...

Embodiment 2

[0060] figure 2 It is a flow chart of the second embodiment of the picking order control method of the present invention. Based on the above embodiment, before sending the picking task to the robot, obtaining a collection of all orders that can be executed by the robot includes:

[0061] S11. Obtain the collection of all issued but unfinished first orders in the current state, and the collection of all second orders to be issued;

[0062] S12. Filter the collection of first orders and the collection of second orders to obtain a collection of third orders that can be executed by the robot.

[0063] In this embodiment, firstly, the collection of all issued but unfinished first orders in the current state and the collection of all second orders to be issued are acquired; then, the collection of the first orders and the collection of all A collection of third orders that can be executed by the robot is obtained by filtering the collection of the second orders.

[0064] Optional...

Embodiment 3

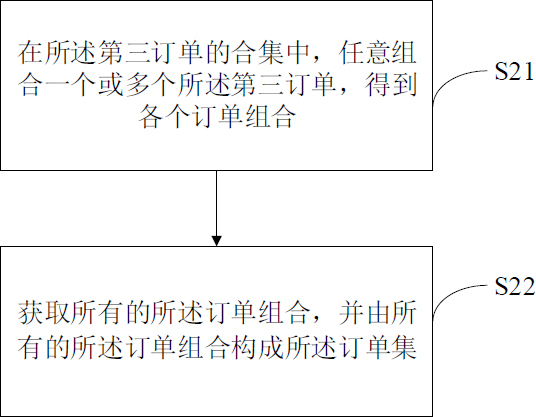

[0070] image 3 It is a flow chart of the third embodiment of the picking order control method of the present invention. Based on the above embodiments, the arbitrary combination of one or more of the orders in the collection obtains an order set composed of multiple order combinations, including :

[0071] S21. In the collection of the third orders, arbitrarily combine one or more of the third orders to obtain each order combination;

[0072] S22. Obtain all the order combinations, and form the order set from all the order combinations.

[0073] In this embodiment, firstly, in the collection of the third orders, one or more of the third orders are combined arbitrarily to obtain each order combination; then, all the order combinations are obtained, and all the The order combination constitutes the order set.

[0074] Optionally, in this embodiment, in the collection of the third orders, one or more third orders to be executed by the same robot are arbitrarily combined to ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com