Patents

Literature

63results about How to "Guaranteed delivery quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Provisioning and management in a message publish/subscribe system

InactiveUS20060146991A1Good resultImprove performanceAutomatic call-answering/message-recording/conversation-recordingProgram controlMessage passingMiddleware architecture

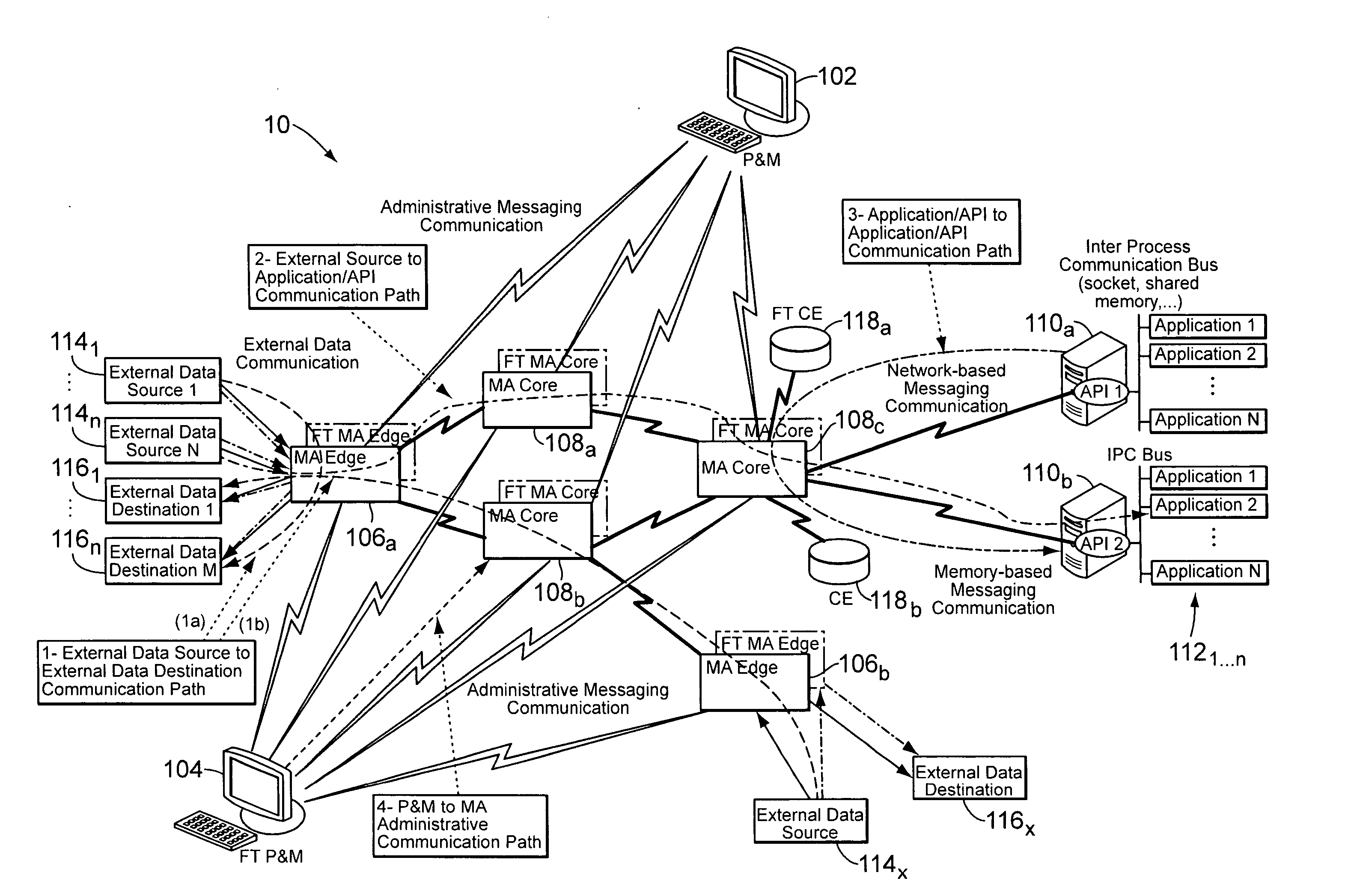

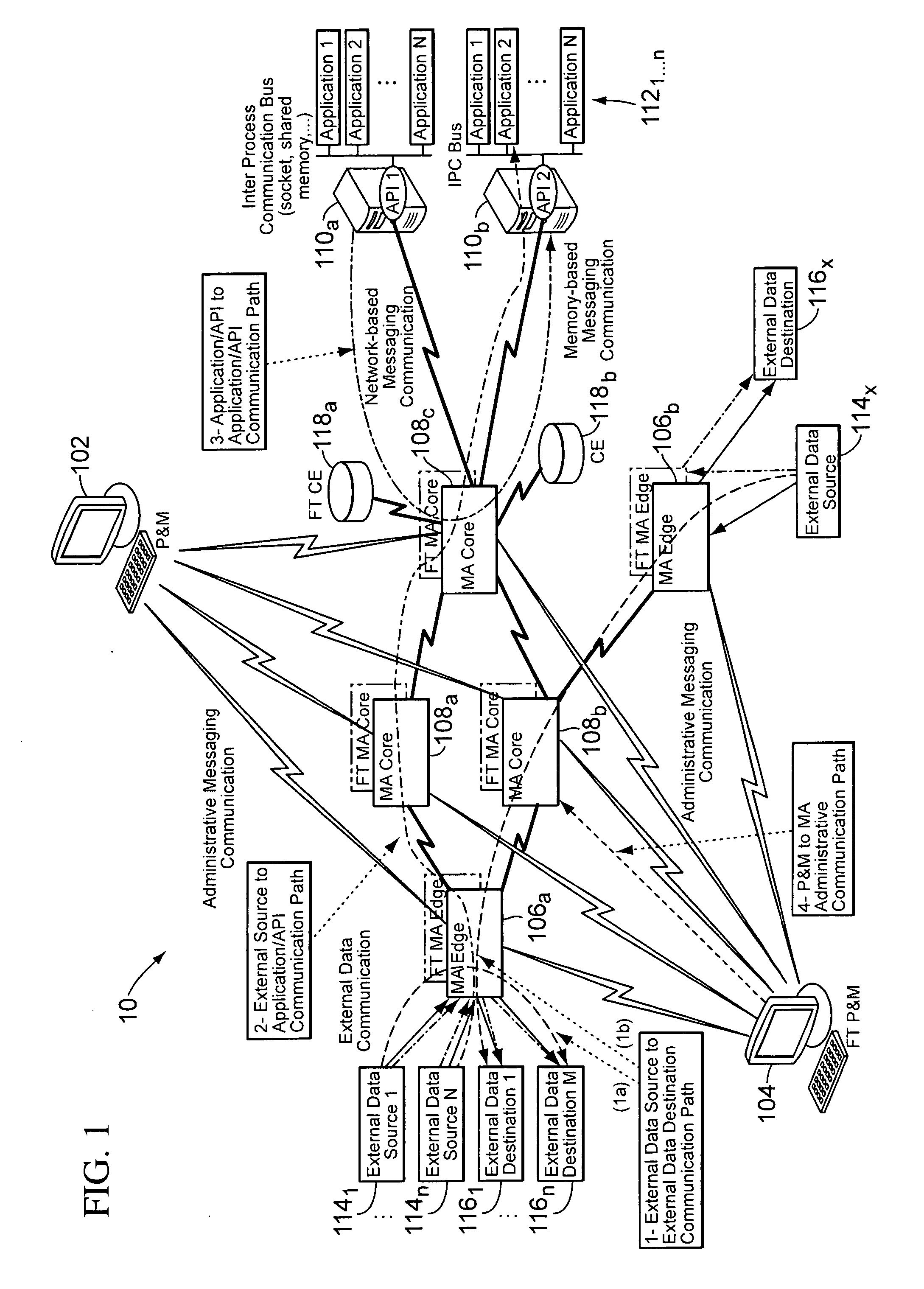

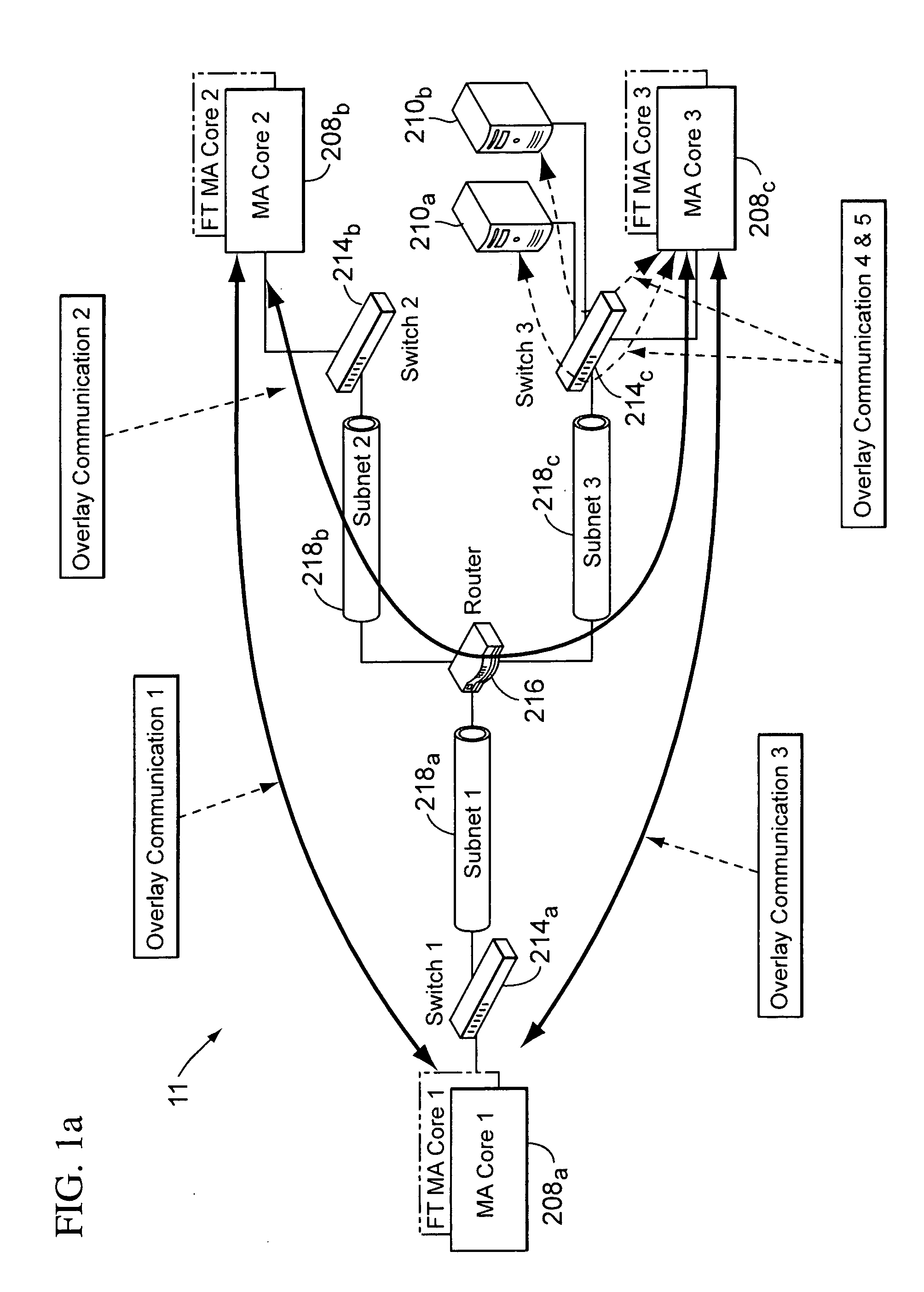

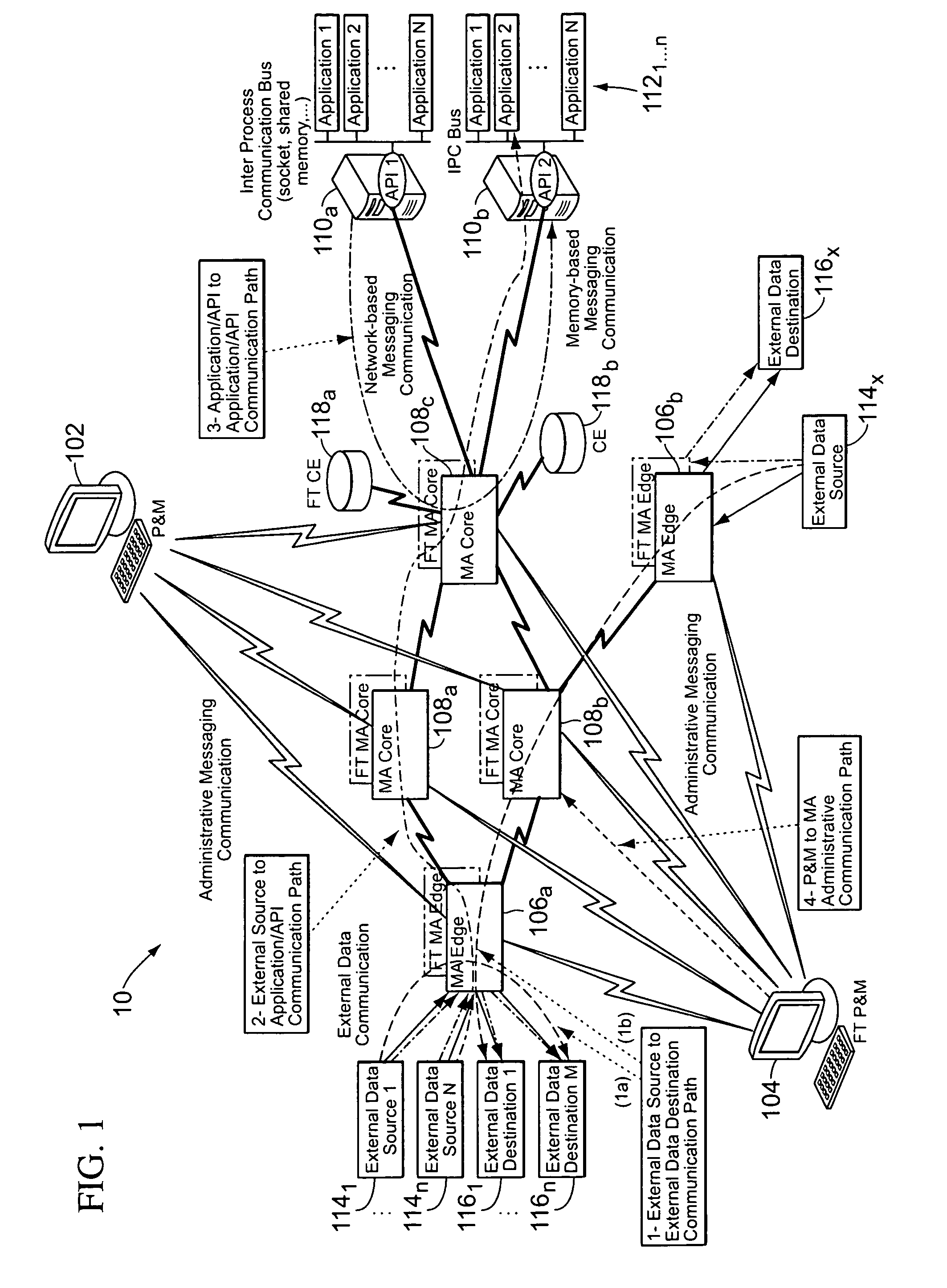

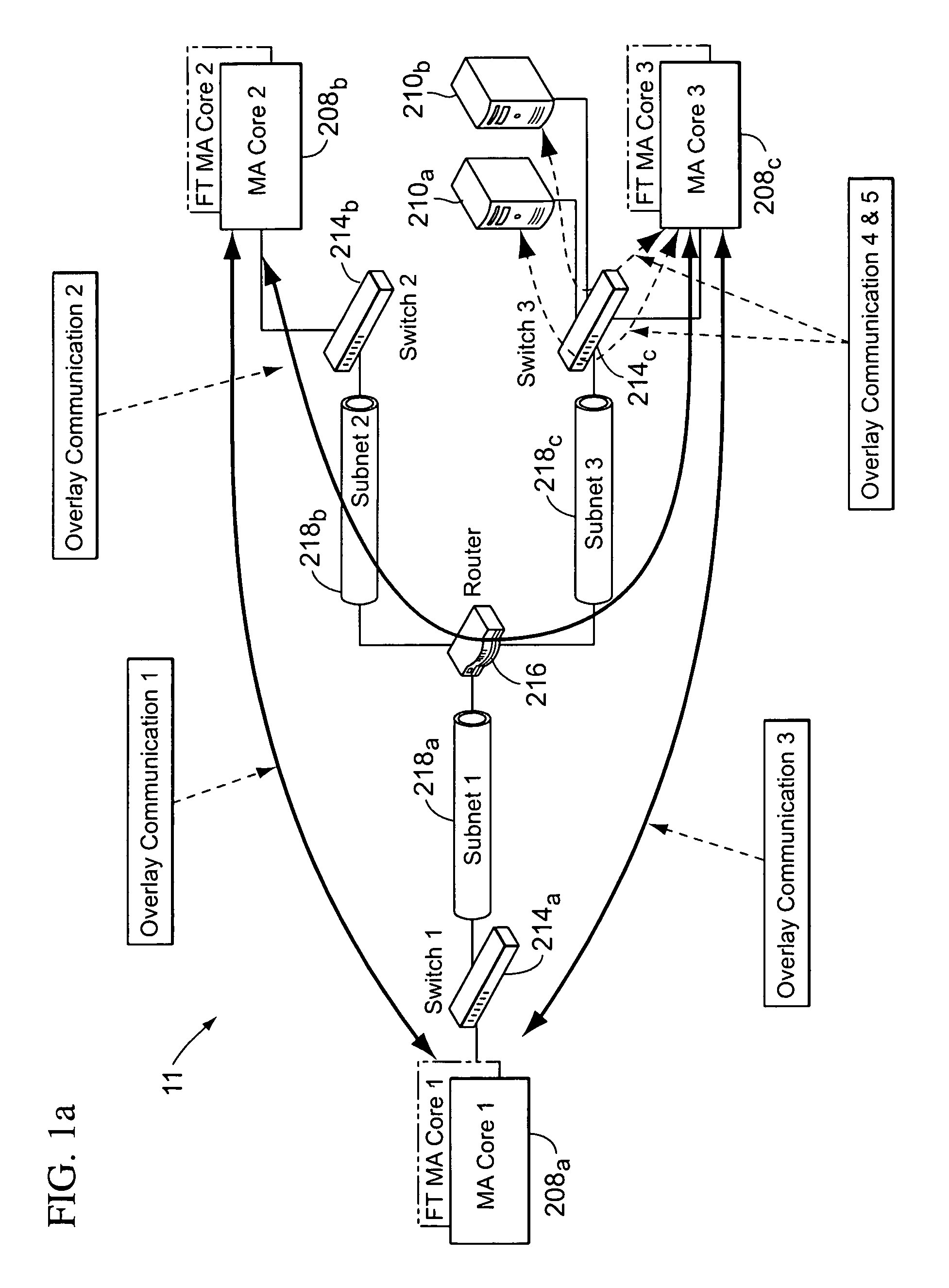

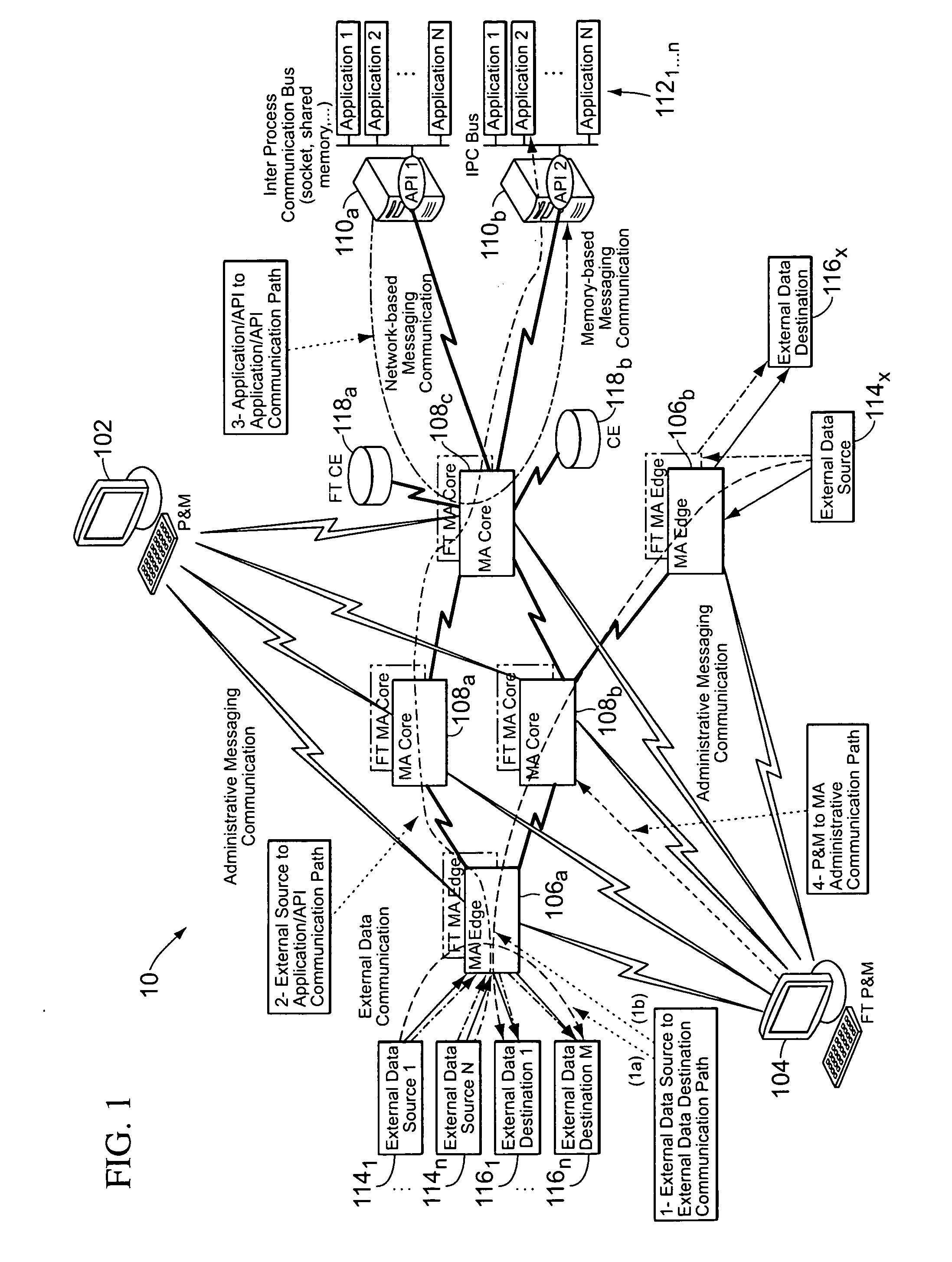

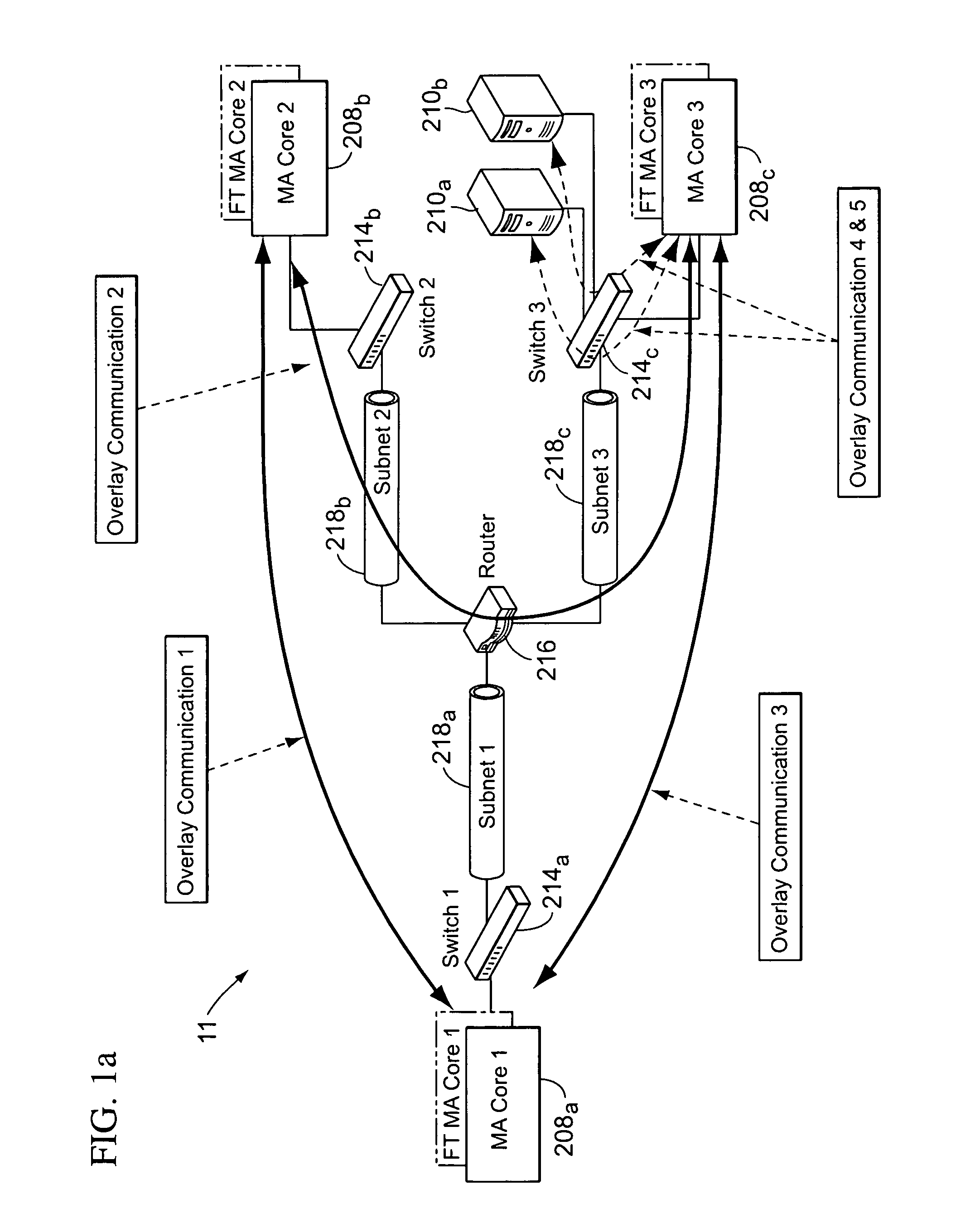

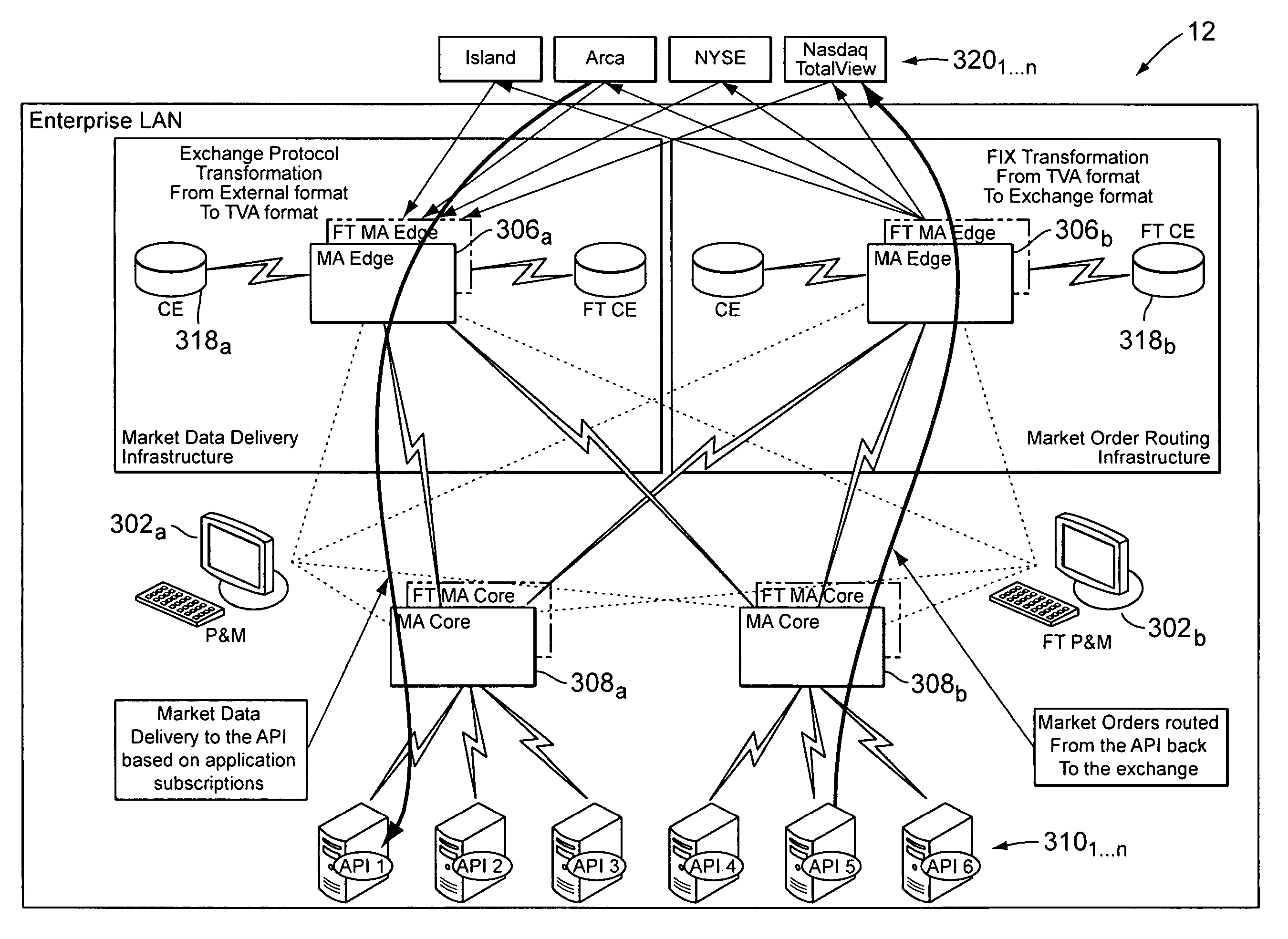

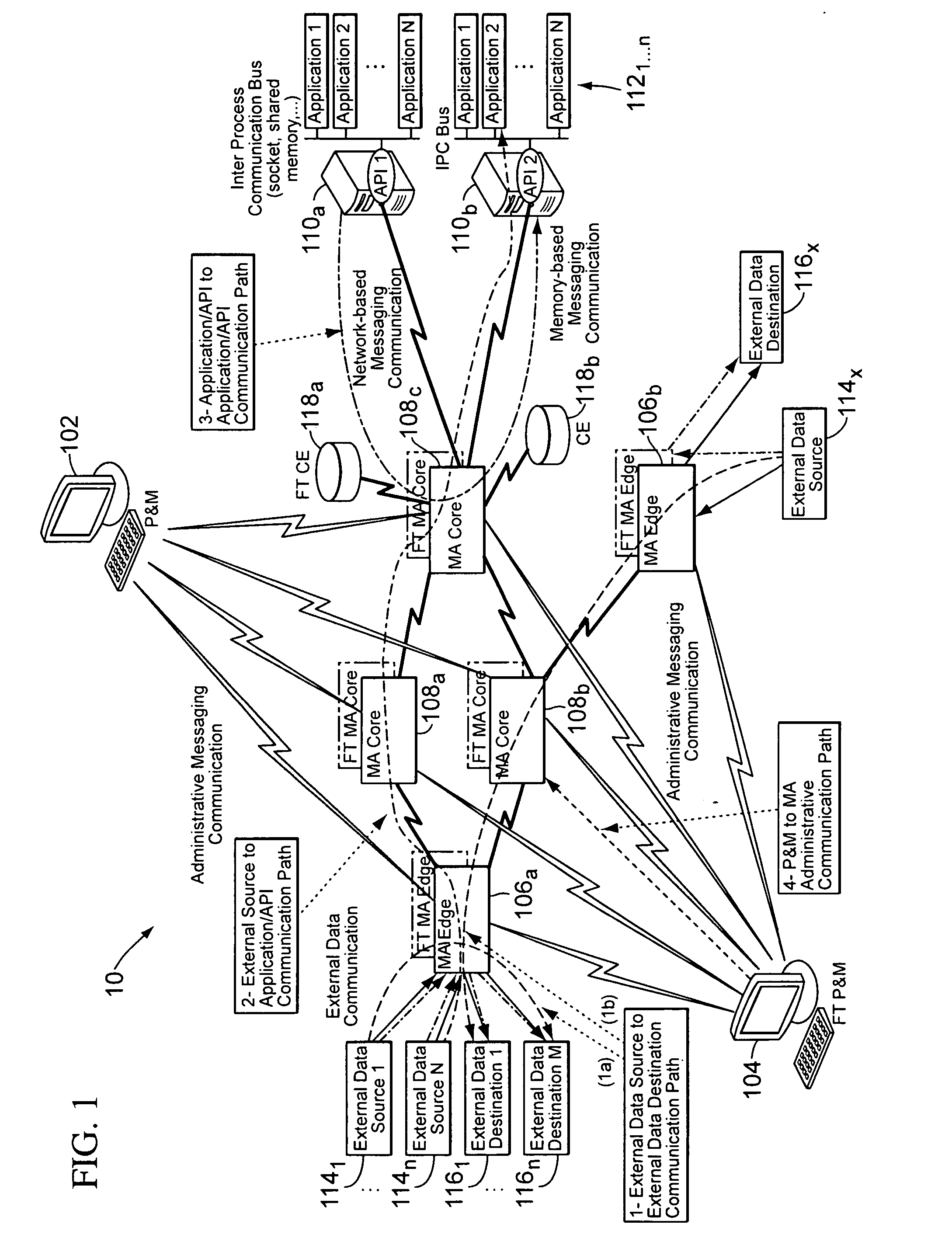

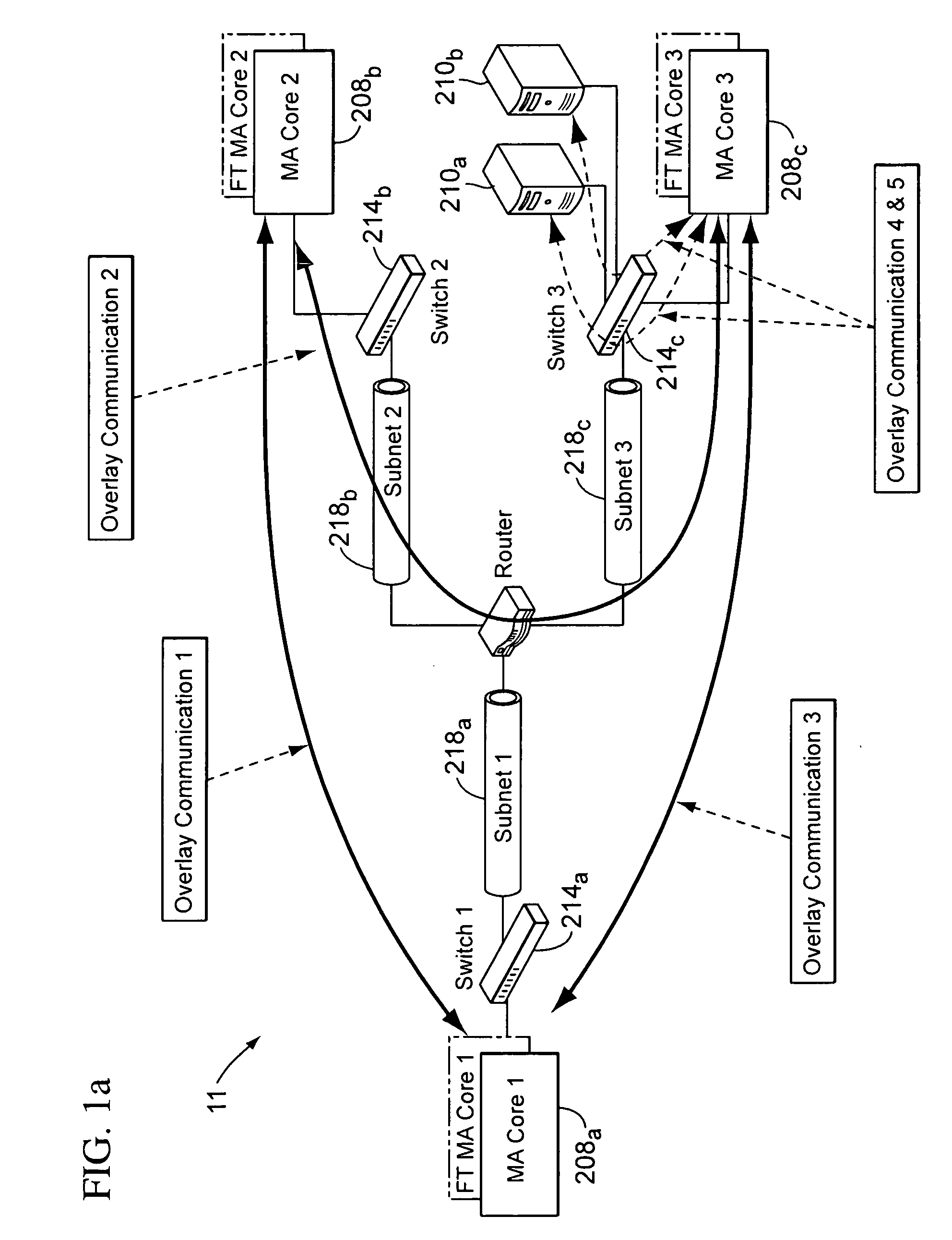

Message publish / subscribe systems are required to process high message volumes with reduced latency and performance bottlenecks. The end-to-end middleware architecture proposed by the present invention is designed for high volume, low-latency messaging by providing, among other things, a central, single point provisioning and management for configuration, provisioning and monitoring system performance. This functionality complements the reduction of intermediary hops through neighbour-based routing and dynamic, real time, optimizing of system interconnect configurations and message transmission protocols.

Owner:TERVELA INC

End-to-end publish/subscribe middleware architecture

InactiveUS7970918B2Guaranteed delivery qualityPromote resultsMultiprogramming arrangementsMultiple digital computer combinationsTransmission protocolMonitoring system

Owner:TERVELA INC

End-to-end publish/subscribe middleware architecture

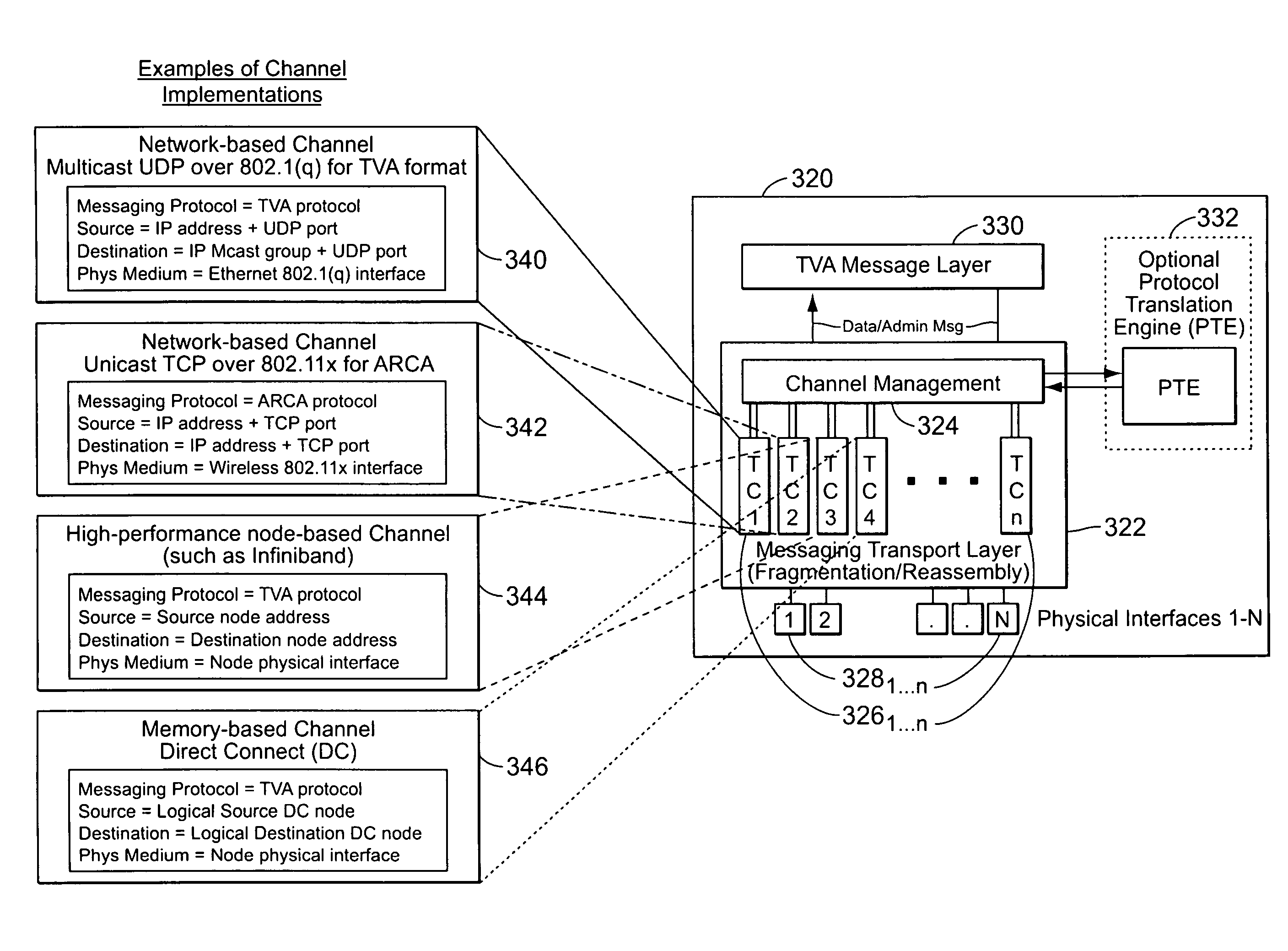

InactiveUS20060149840A1Promote resultsHigh messaging volumeDigital computer detailsData switching networksTransmission protocolLatency (engineering)

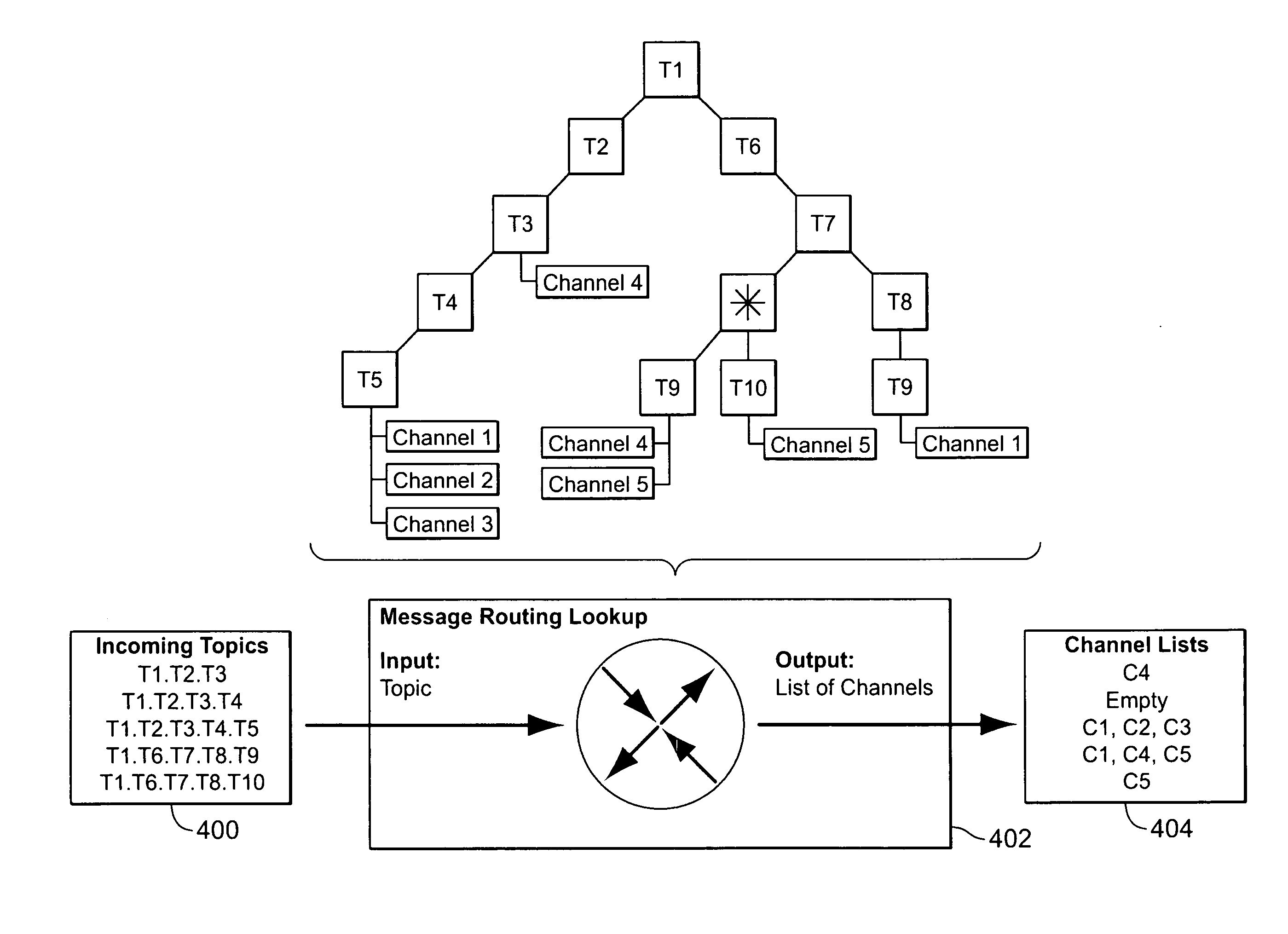

Message publish / subscribe systems are required to process high message volumes with reduced latency and performance bottlenecks. The end-to-end middleware architecture proposed by the present invention is designed for high-volume, low-latency messaging by, among other things, reducing intermediary hops with neighbor-based routing, introducing efficient native-to-external and external-to-native protocol conversions, monitoring system performance, including latency, in real time, employing topic-based and channel-based message communications, and dynamically optimizing system interconnect configurations and message transmission protocols.

Owner:TERVELA INC

Hardware-based messaging appliance

InactiveUS20060168070A1Guaranteed delivery qualityPromote resultsMultiple digital computer combinationsProgram controlTransmission protocolDynamical optimization

Owner:TERVELA INC

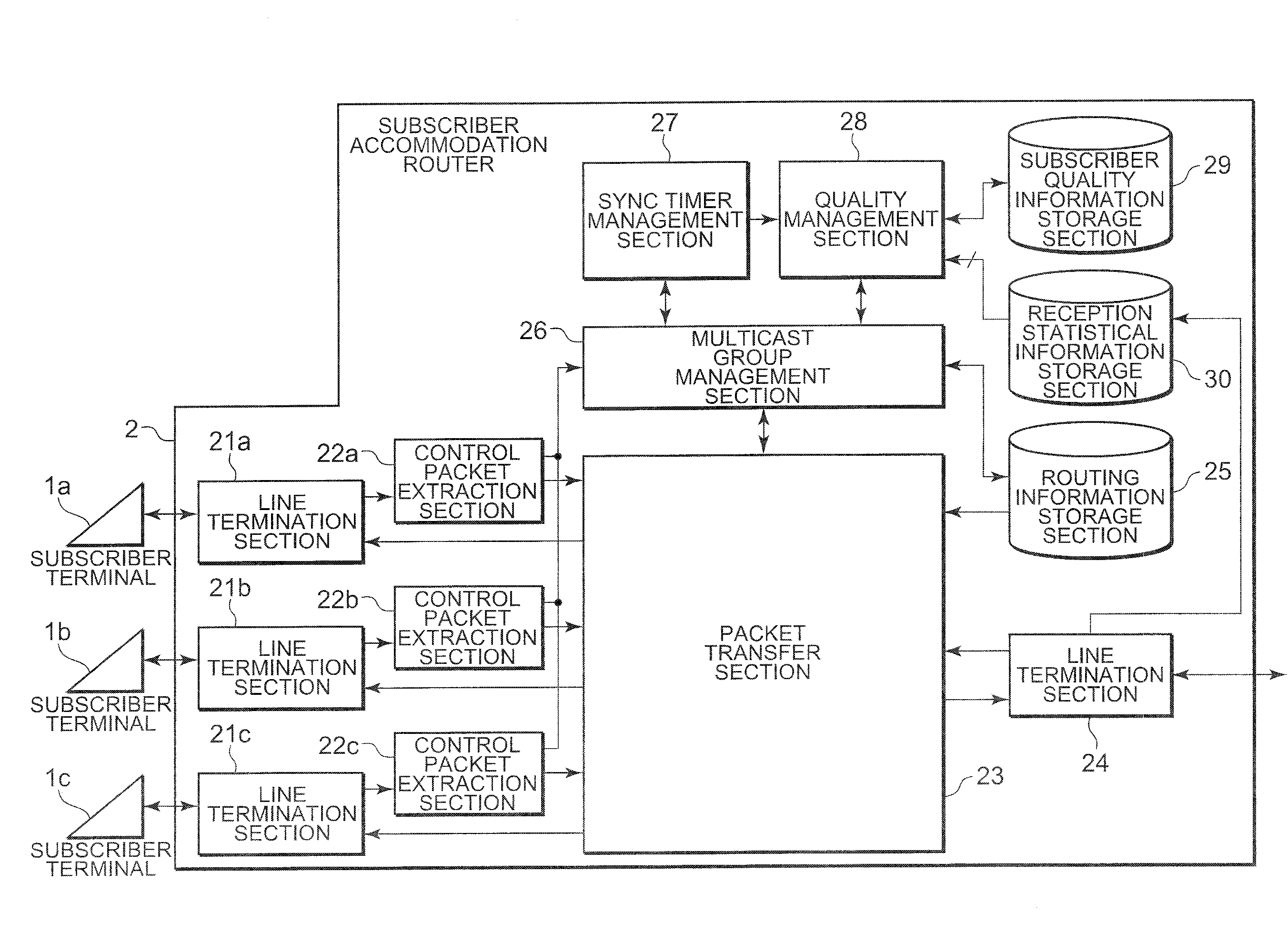

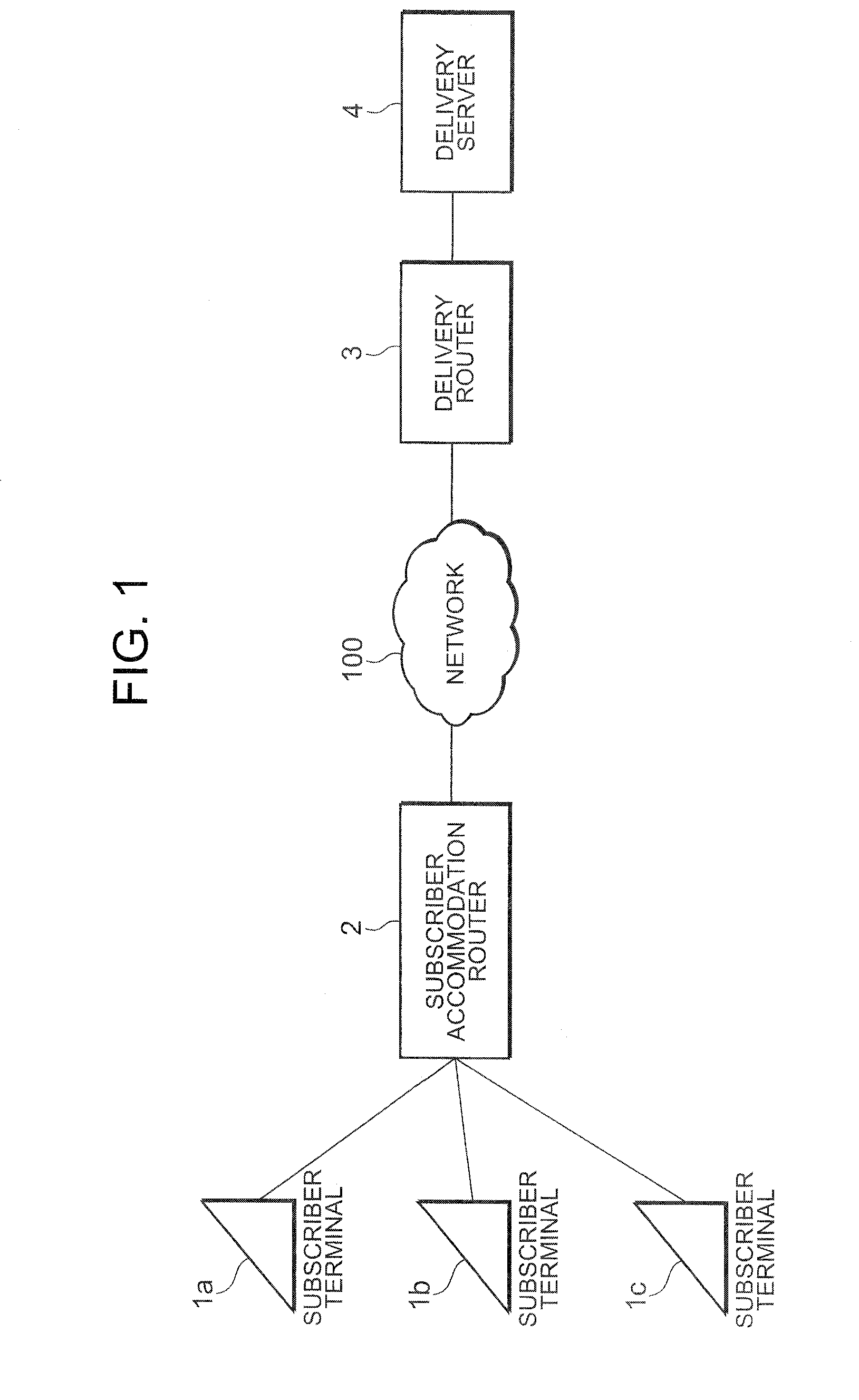

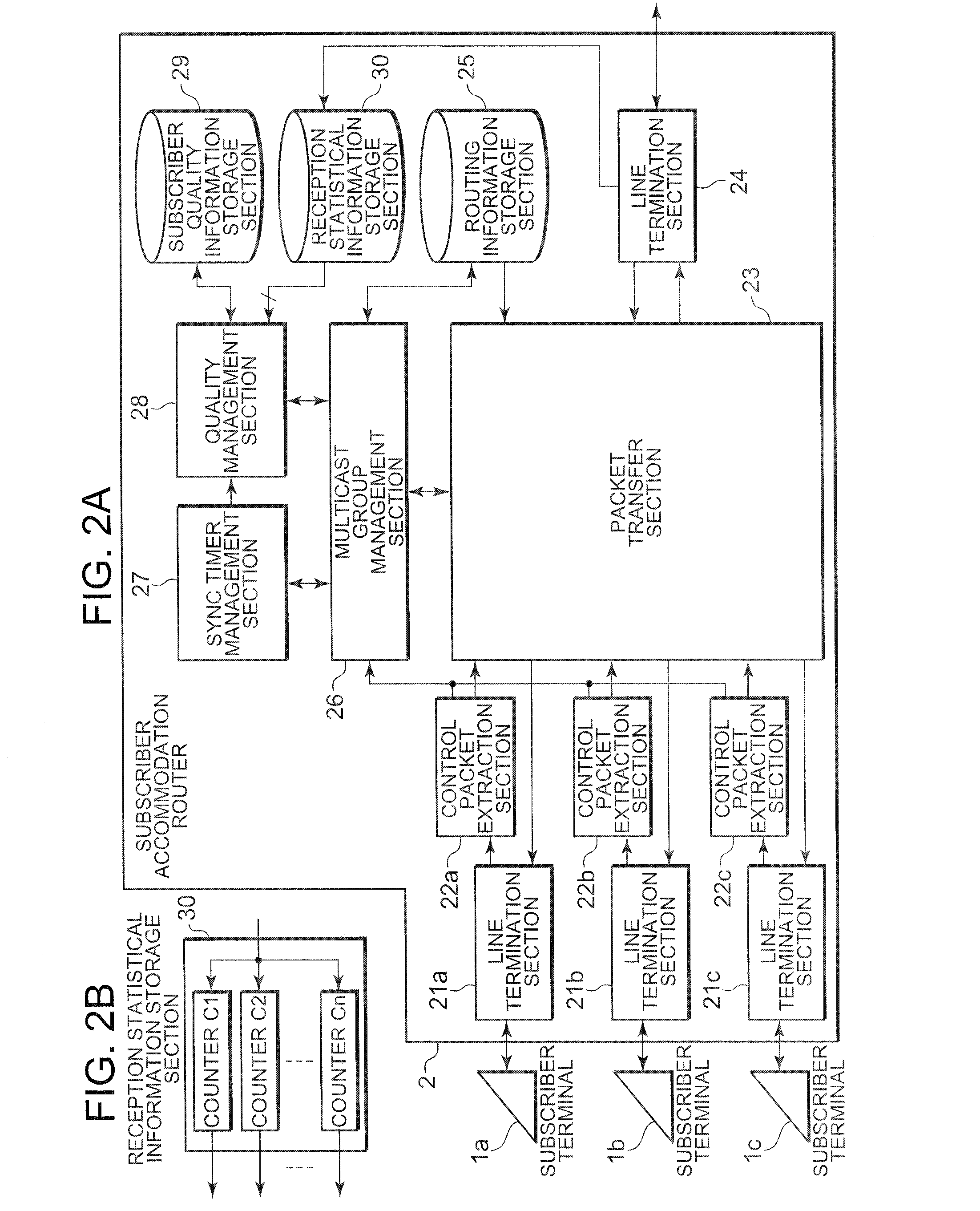

Method and system for measuring packet delivery quality

InactiveUS20070280108A1Reduce trafficEfficient collectionError preventionTransmission systemsNetwork packetMulticast network

A system measures delivery quality of data packets transmitting from a communication device to at least one communication terminal through a multicast network. The system includes a communication section for periodically transmitting a first packet to a communication terminal and receiving a second packet in response to the first packet from the communication terminal. The second packet includes delivery quality information. The system further includes a measuring section for measuring the delivery quality of data packets based on the delivery quality information.

Owner:NEC CORP

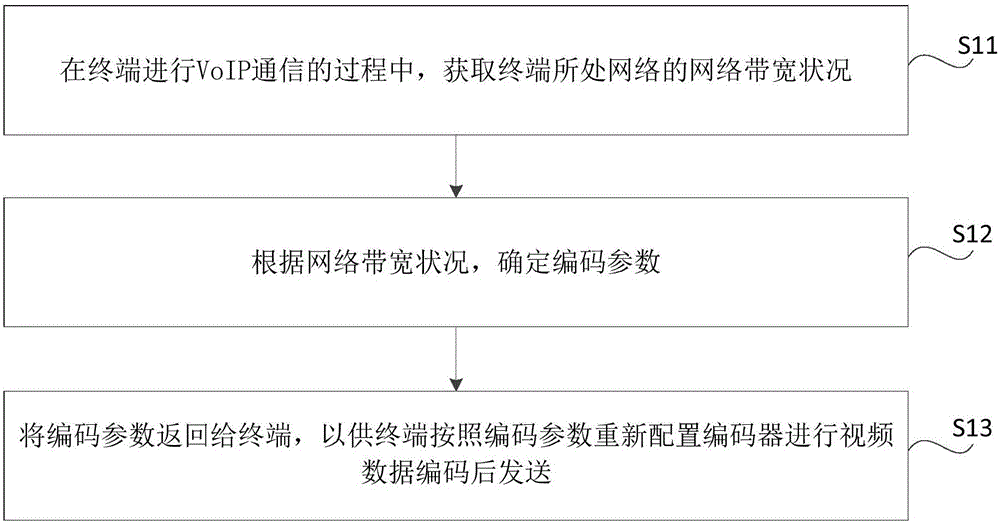

VoIP communication method and apparatus

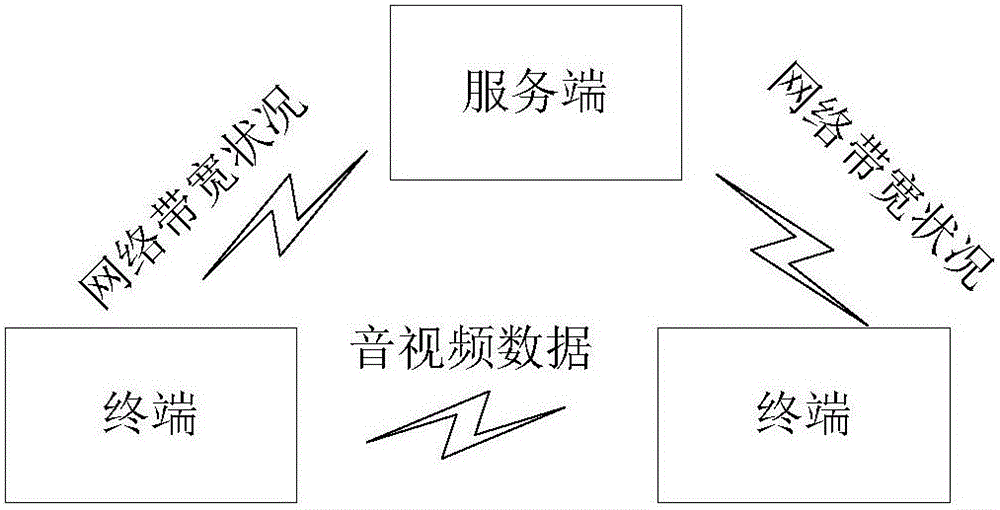

ActiveCN106231353AAvoid congestionGuaranteed delivery qualityDigital video signal modificationTransmissionImage resolutionDistributed computing

The invention discloses a VoIP communication method and apparatus. The VoIP communication method comprises steps: obtaining the network bandwidth condition of a network which a terminal belongs to in a VoIP communication process of the terminal; determining coding parameters according to the network bandwidth condition; and sending the coding parameters to the terminal so that the terminal reconfigures an encoder for video data coding according to the coding parameters and then sends the parameters. According to the method and apparatus, the technical problem of poor service quality of VoIP is solved, the coding parameters such as resolution, frame rate, and code rate are adjusted according to the network bandwidth condition, network congestion is avoided, and the service quality is guaranteed.

Owner:BEIJING XIAOMI MOBILE SOFTWARE CO LTD

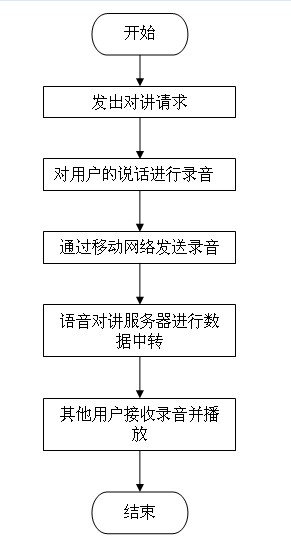

Method for realizing vehicle-mounted voice intercom by using mobile network

ActiveCN102665175AGuaranteed delivery qualityLow costBroadcast service distributionTransmissionSpeech soundMobile Web

A method for realizing vehicle-mounted voice intercom by using a mobile network aims at overcoming the defects that the call quality cannot be ensured or the call cost is higher in traditional voice intercom in the prior art. The invention provides the method for realizing the vehicle-mounted voice intercom by using the mobile network. Hardware comprises a set of vehicle-mounted navigator and voice intercom server; the vehicle-mounted navigator and the voice intercom server form a voice intercom system through the mobile network; and a voice intercom program is installed on the vehicle-mounted navigator. The method mainly comprises five steps, namely transmitting an intercom request, recording the speaking content of a user, transmitting the record through the mobile network, transferring data by the voice intercom server and receiving and playing the record by other users. According to the method disclosed by the invention, the transmitting quality of voice is ensured and the cost of intercom between users is reduced; and the method is suitable for environments for carrying out vehicle-mounted voice intercom.

Owner:SHENZHEN ROADROVER TECH

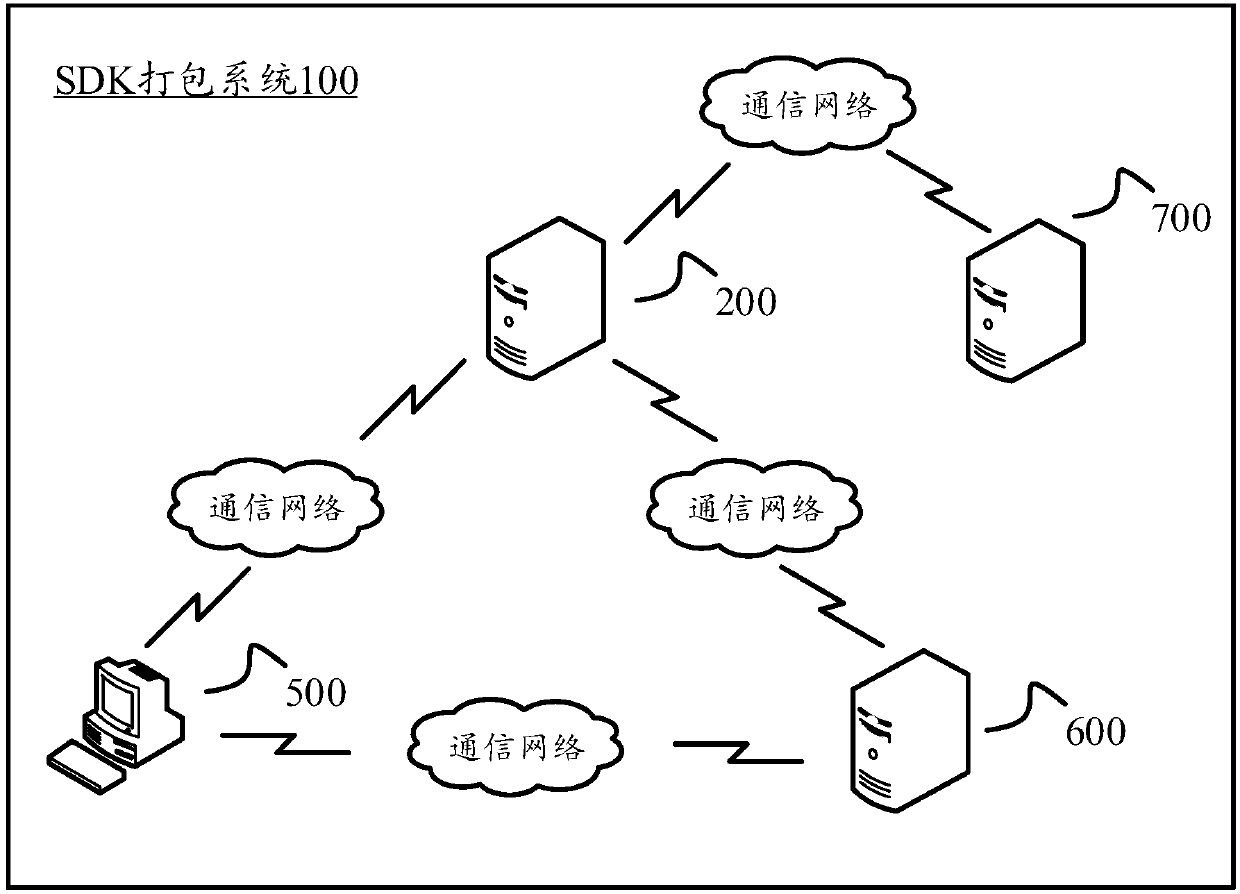

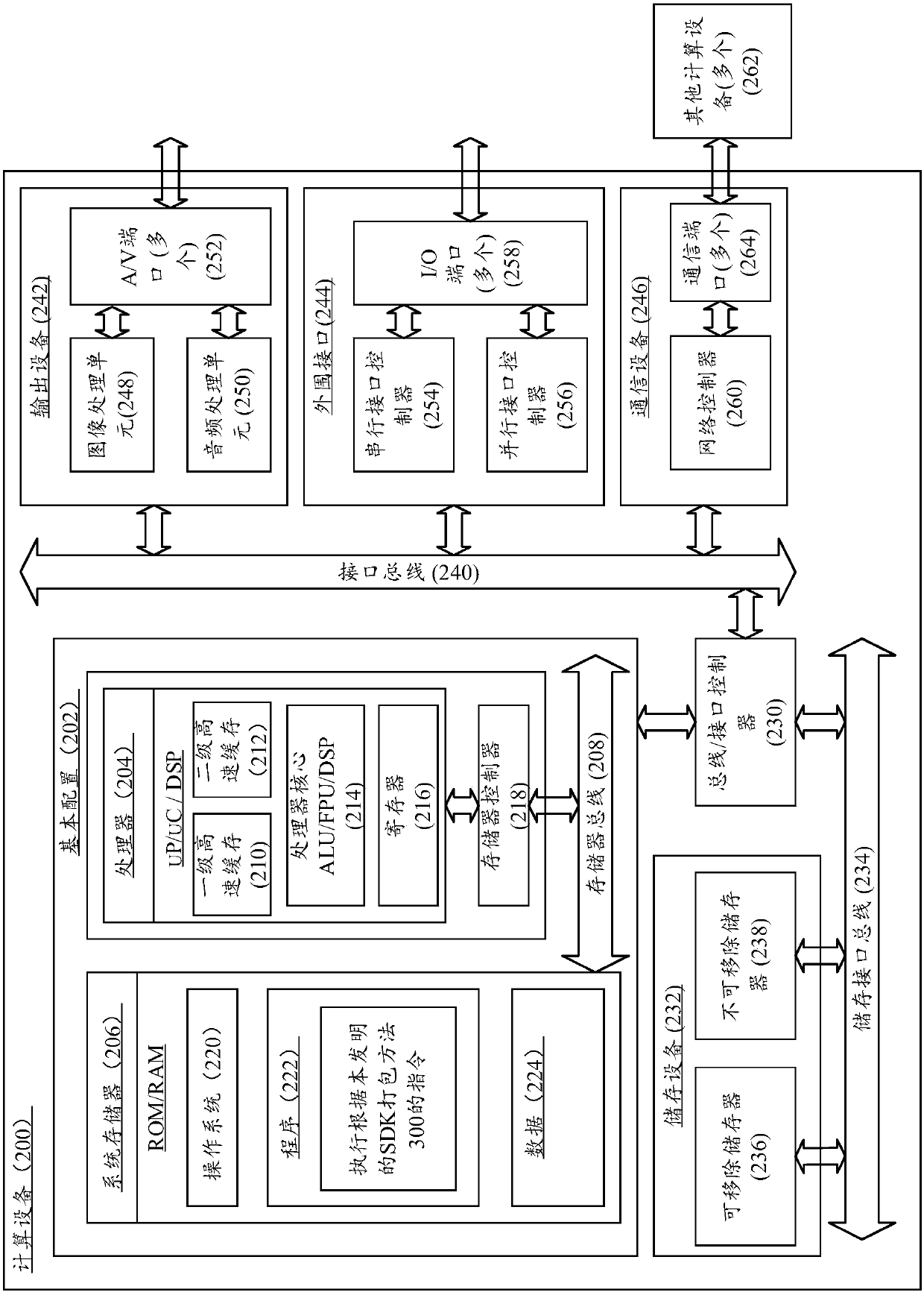

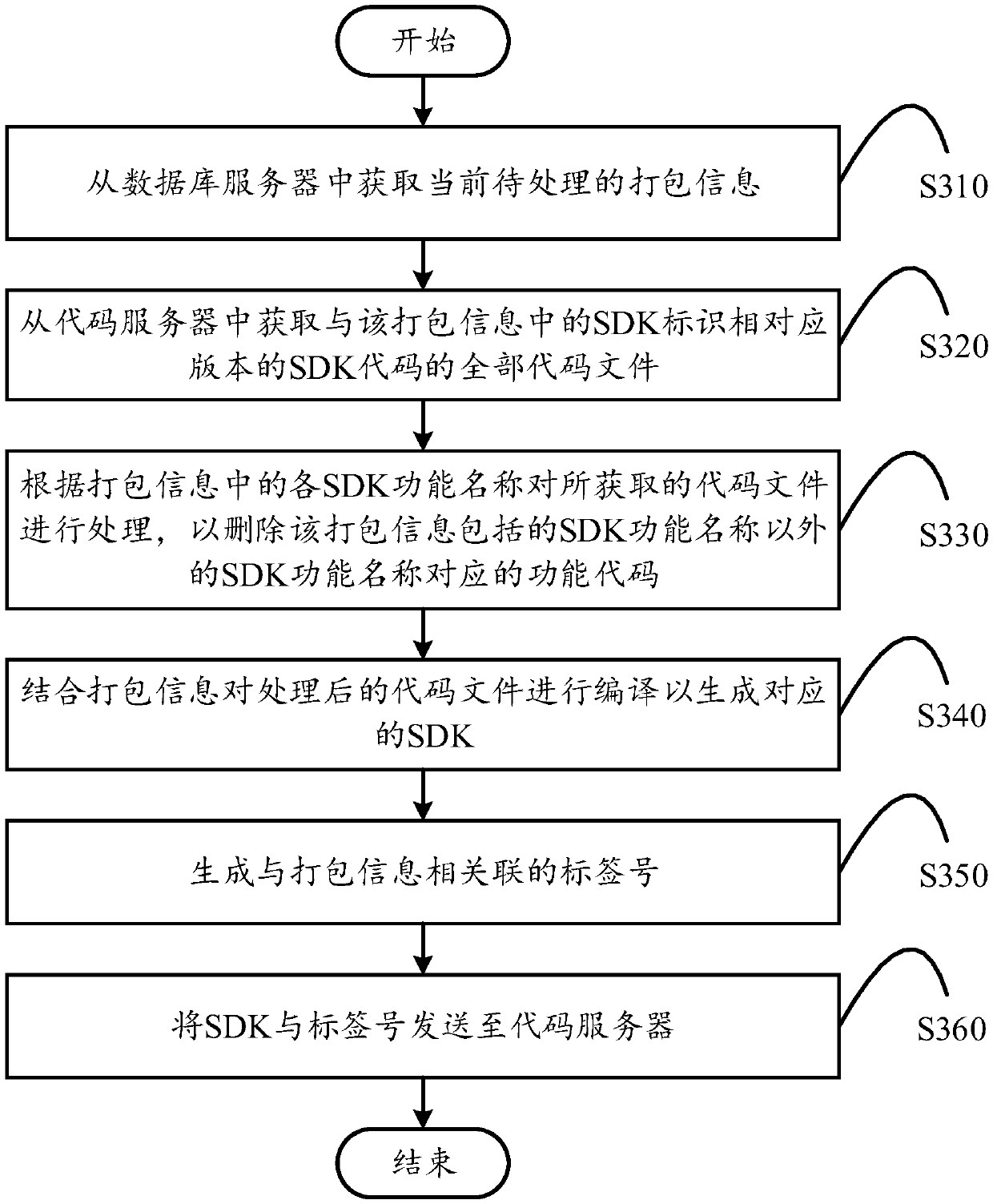

SDK packaging method, computing equipment and SDK packaging system

InactiveCN107678750AImprove accuracyEasy to cutVersion controlSoftware deploymentDatabase serverFunction Code

The invention discloses an SDK packaging method suitable for being executed in computing equipment. The computing equipment is in communicating connection with a database server and a code server, wherein multiple pieces of packaging information are stored in the database server, and SDK codes in multiple versions are stored in the code server. The method comprises the steps that current to-be-processed packaging information is acquired from the database server; all code files of the SDK codes in the version corresponding to an SDK identifier in the packaging information are acquired from thecode server; the acquired code files are processed according to all SDK function names in the packaging information to delete function codes corresponding to SDK function names except the SDK functionnames included in the packaging information; the processed code files are compiled in combination with the packaging information to generate a corresponding SDK; a tag number associated with the packaging information is generated; and the SDK and the tag number are sent to the code server.

Owner:BEIJING TENGYUN TIANXIA SCI & TECH CO LTD

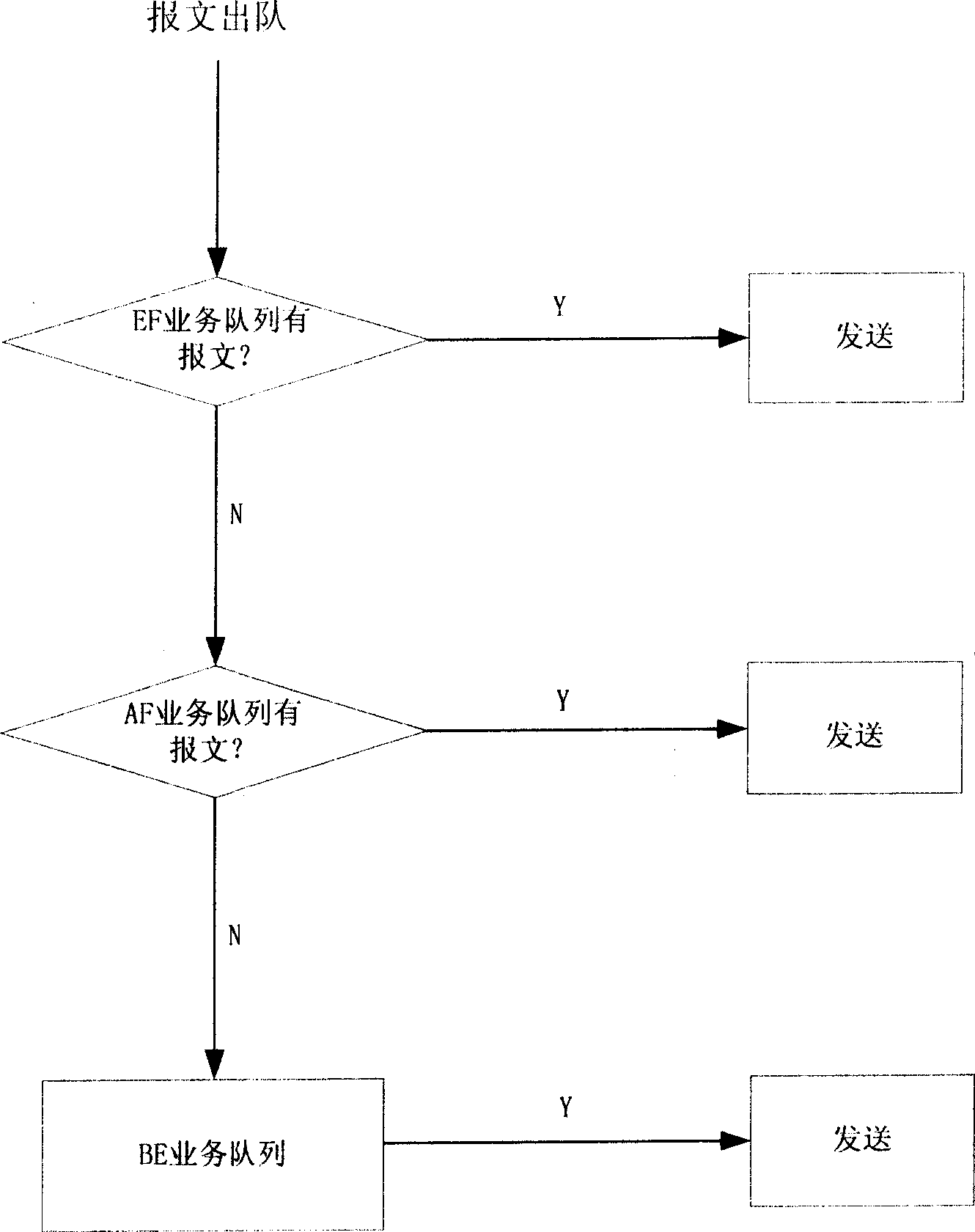

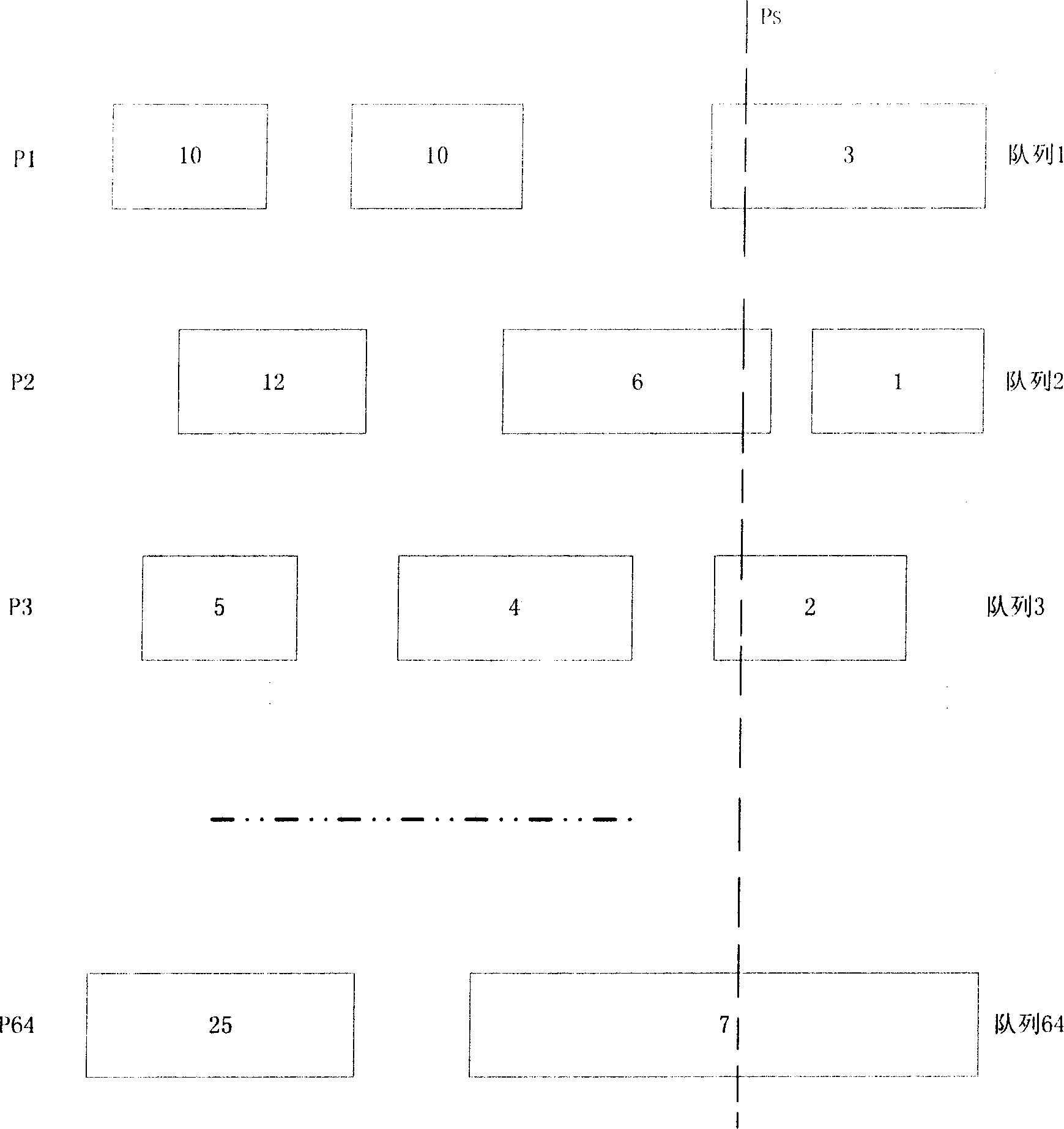

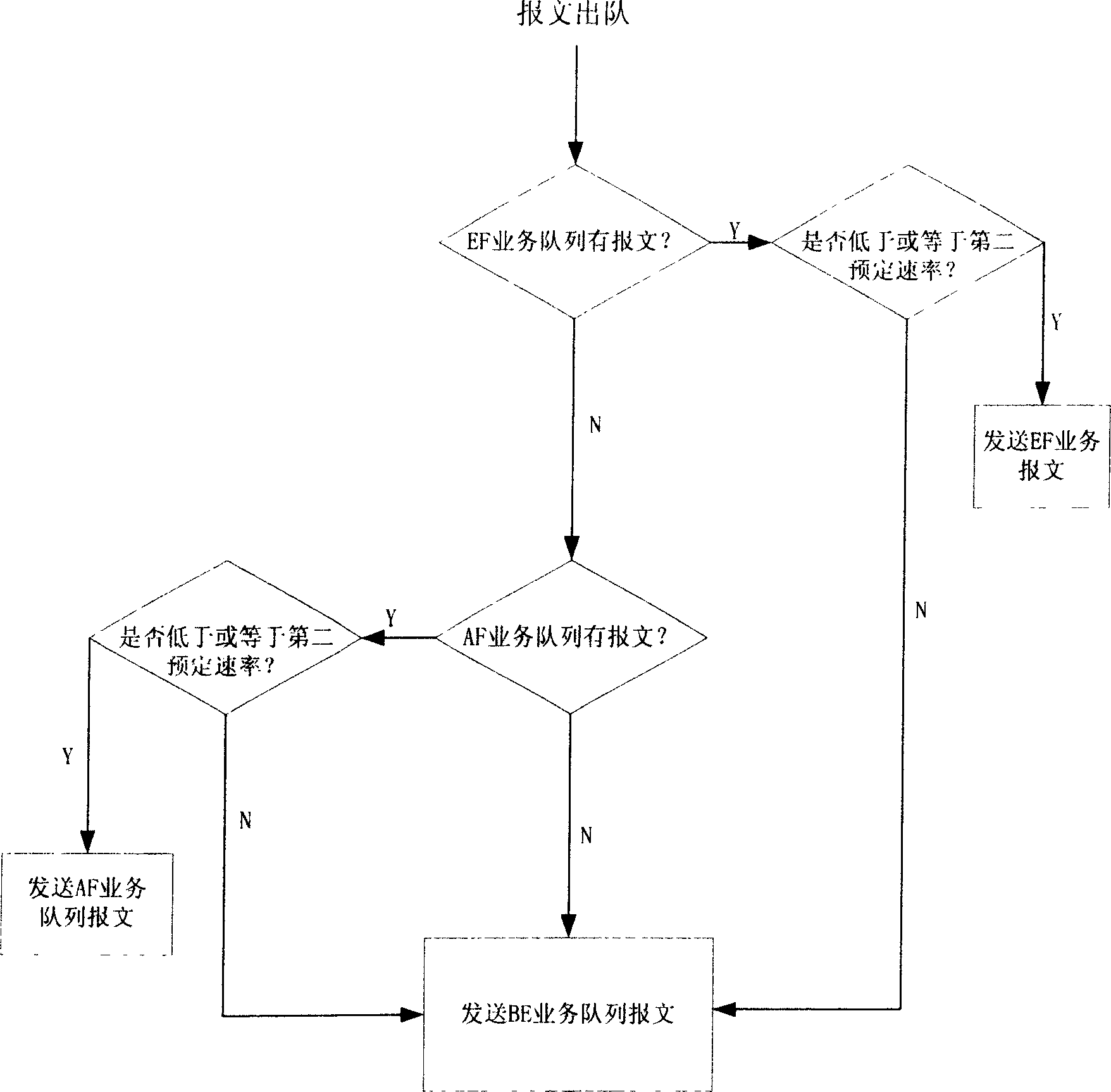

Method of implementing integrated queue scheduling for supporting multi service

InactiveCN1518296AGuaranteed delivery qualityGuaranteed bandwidthData switching networksSelection arrangementsRate limitingDistributed computing

A method for implementing the integrated queue scheduling to support multiple services is disclosed. When predefined first priority message is added to queue, the speed at which the message in different class comes the queue relative to the first priority transmitted group is limited by the predefined first speed. If its speed is lower than or equal to the predefined first speed, it can come in the queue. If it is not it is rejected. When predefined first and second priority messages go out of the queue and the message in default queue is detected, their speed is limited by a predefined second speed. If their speed is lower than or equal to the predefined second speed, they can be transmitted. Or the predefined third message is transmitted.

Owner:HUAWEI TECH CO LTD

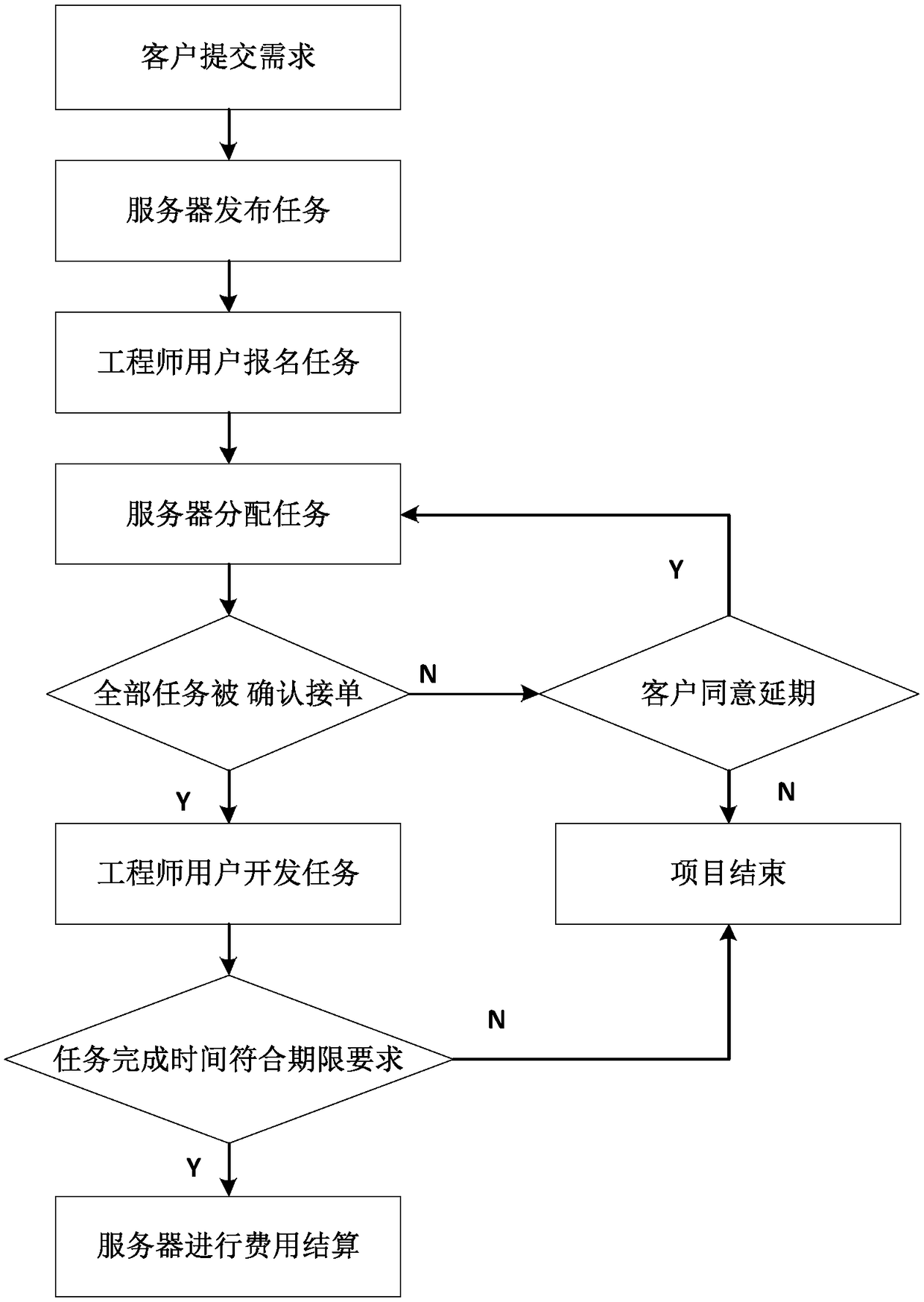

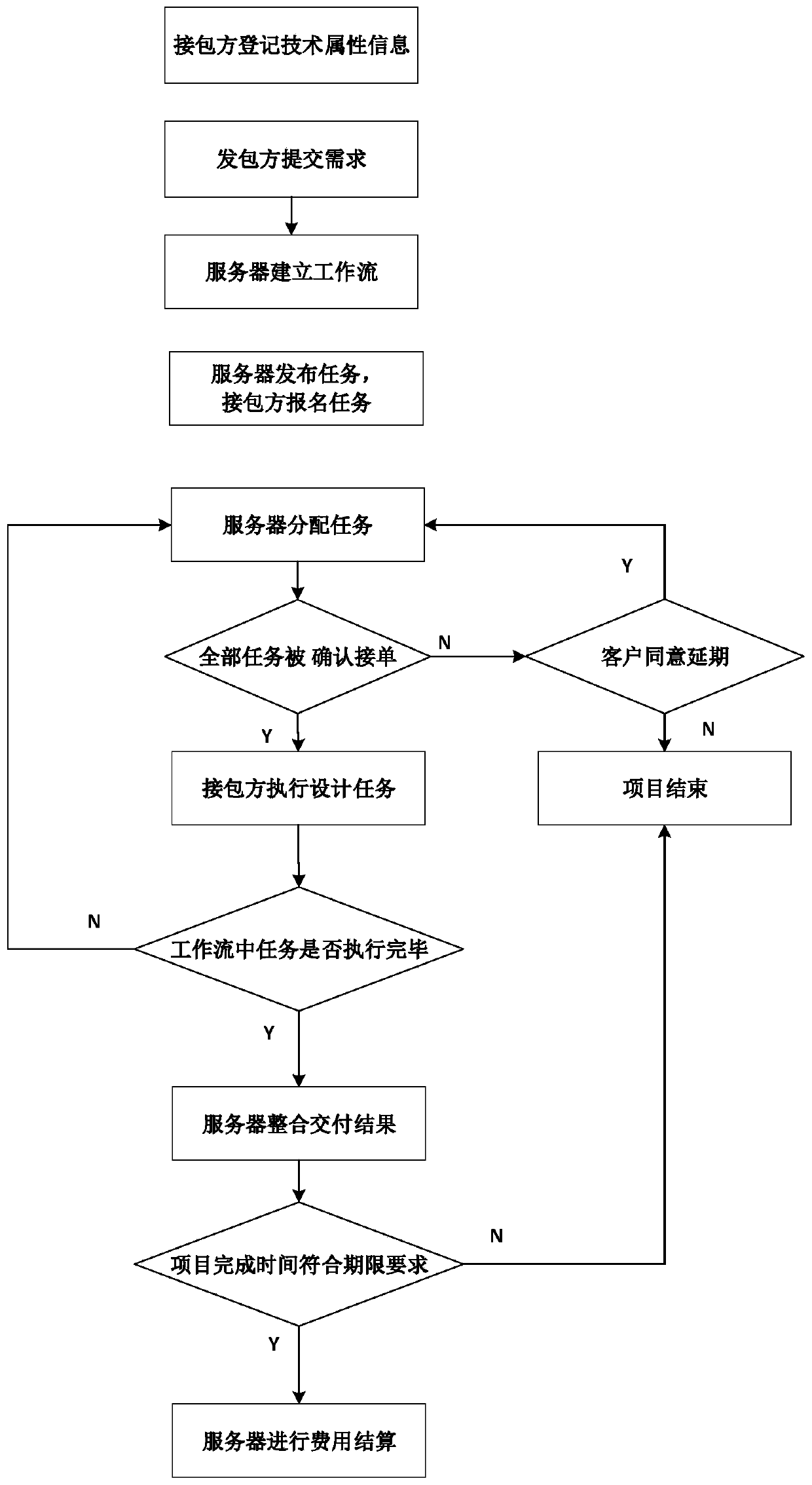

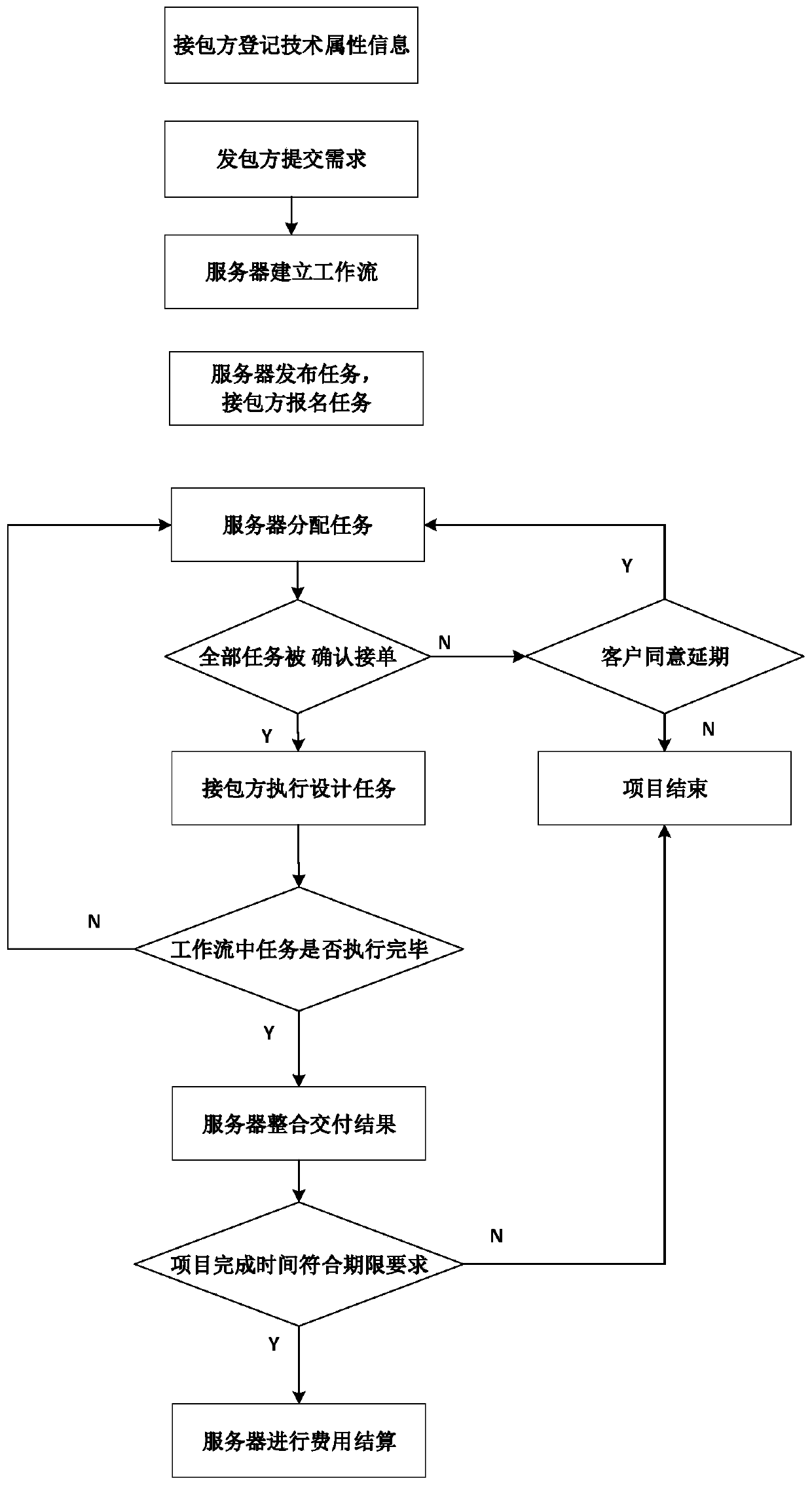

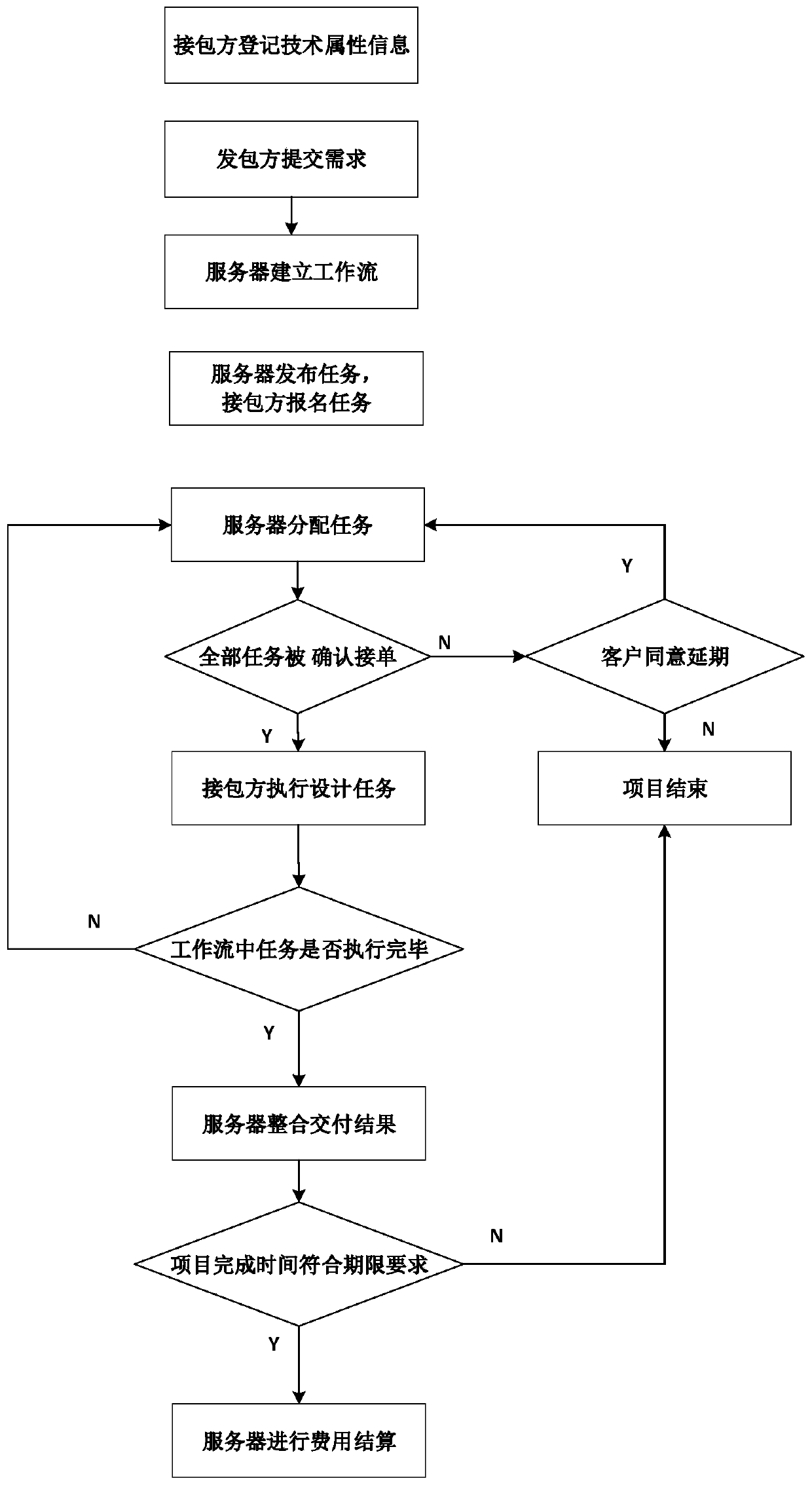

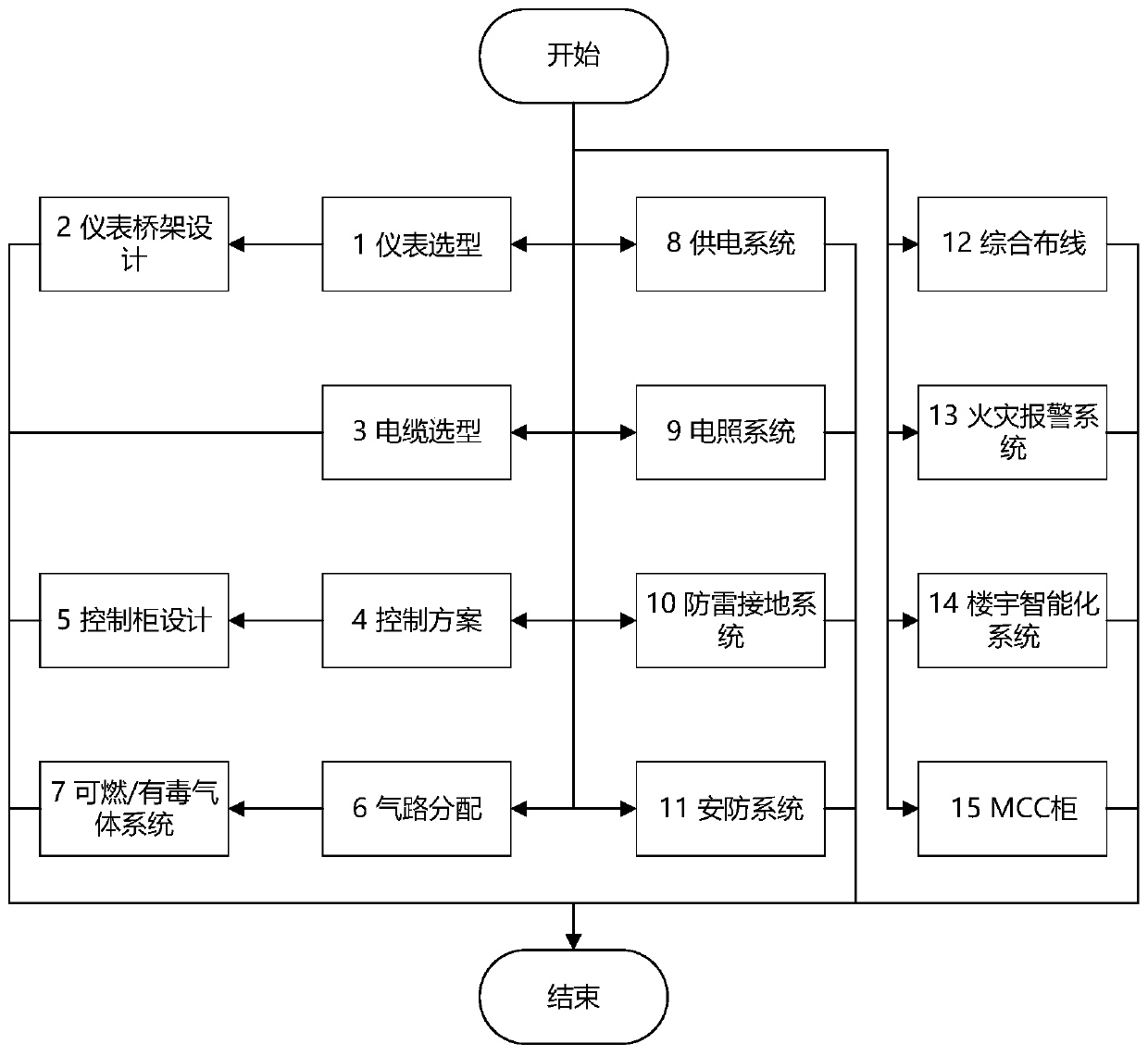

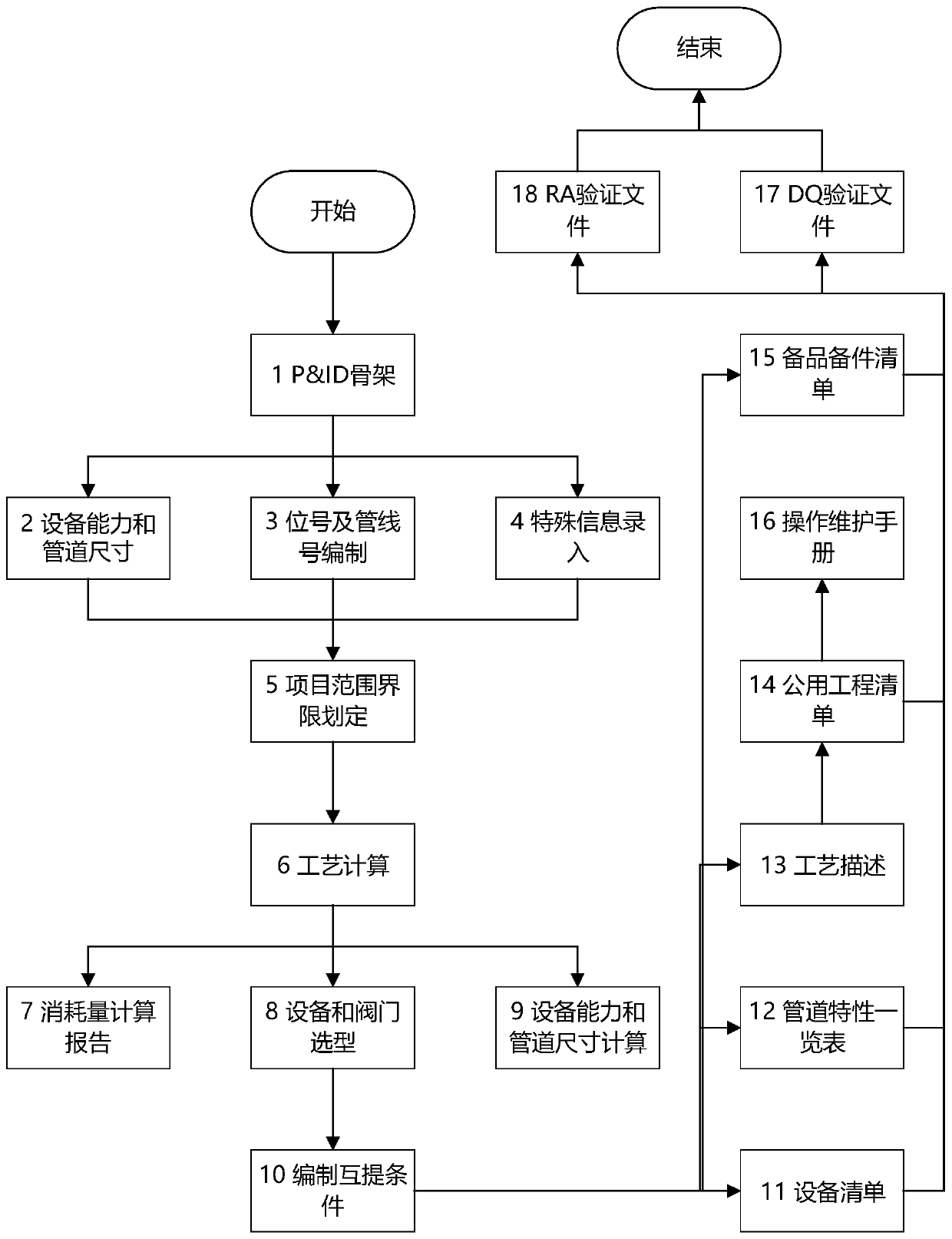

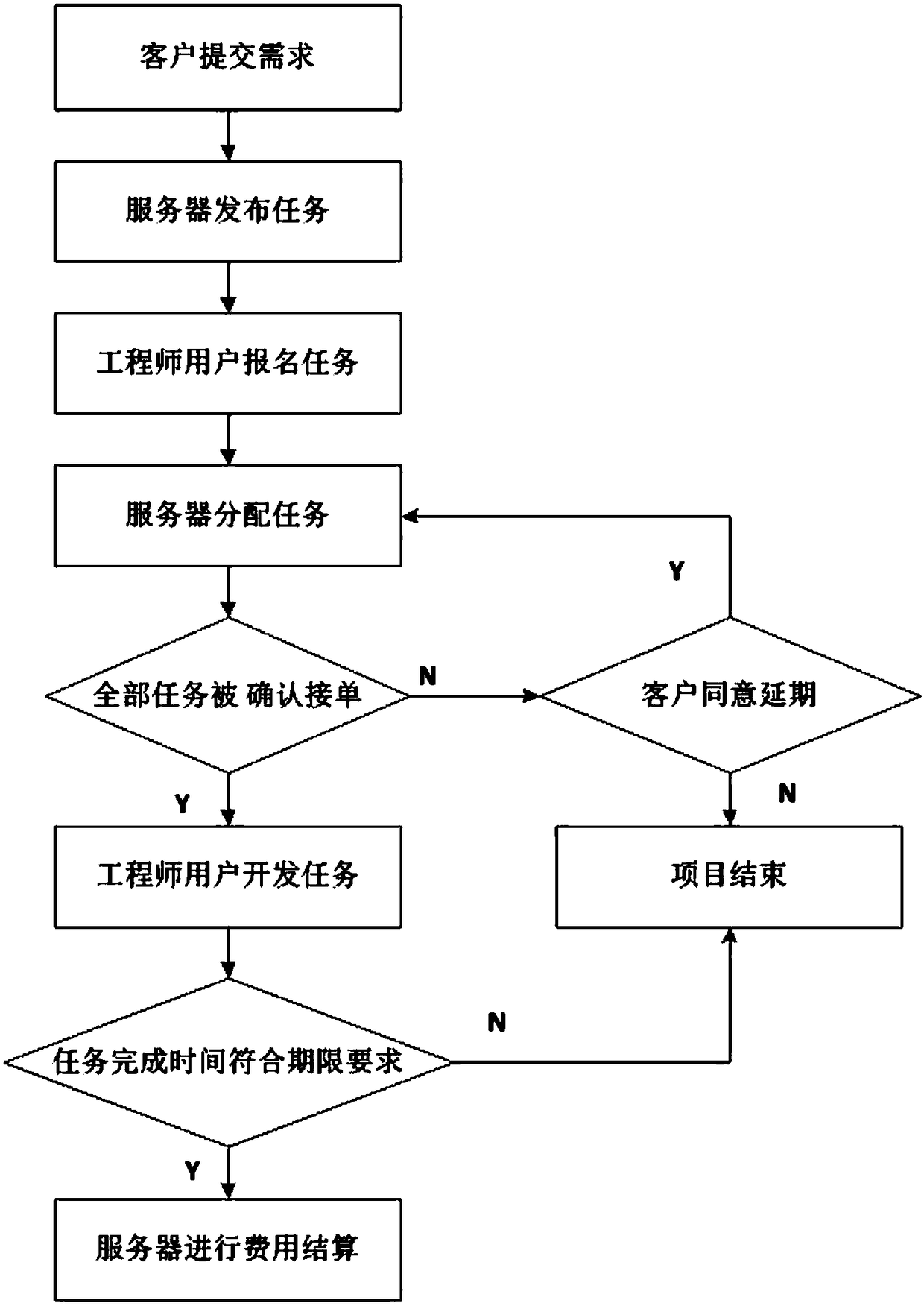

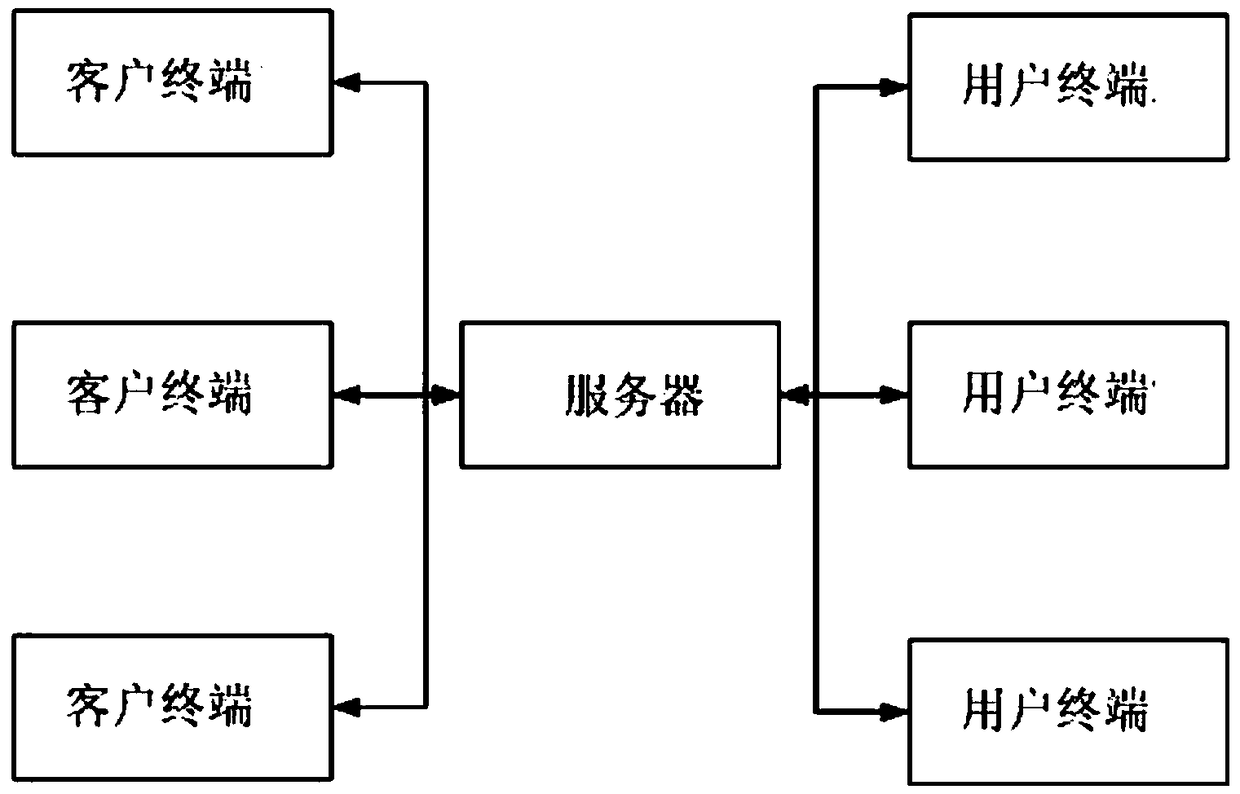

Design work management method, platform and system for accelerated delivery

InactiveCN108876202AReduce communication workloadFast deliveryResourcesCompletion timeProject completion

The invention discloses a design work management method, platform and system for accelerated delivery. The method comprises the steps: calculating the total design workload and total design cost according to a design project demand sent by a client through a client terminal, dividing the design project demand into a plurality of tasks, and issuing the tasks, wherein the tasks comprise one main design task and a plurality of common design tasks, and the sum of the completion time of the main design task and the completion time of the common design tasks is less than a task deadline; distributing all tasks to user terminals, and setting the task deadlines, so as to guarantee that the completion time of all tasks are within a specified time of a self-distribution task moment; receiving completed design scripts sent by all terminals, transmitting a delivery result to the client terminal, and checking whether the completion time of each task meets the task deadline requirement or not: transmitting a project completion message to the client terminal if the completion time of each task meets the task deadline requirement, or else transmitting a design failure message to the user terminals. The method increases the software design speed, and guarantees the accelerated delivery.

Owner:武汉空心科技有限公司

Rapid delivery self-control design work management method, platform and system

InactiveCN109740851AReduce communication workloadFast deliveryResourcesPersonal accountBusiness process

The invention discloses a rapid delivery self-control design work management method, platform and system. The method comprises the steps that a packet receiver registers a personal account and registers personal technical attribute information; the packet sender issues a self-control design project demand and hosts project cost; the server establishes a project workflow and a task group accordingto self-control design project requirements; the server executes the workflow, the project workflow comprises an audit level label, and subtasks in the task group are sent to a user terminal of a packet receiver conforming to the technical attribute of the subtasks; the packet receiver sends an instruction of subtask application; the packet receiver completes task uploading and delivery results within the task deadline; the server notifies the packet sender to check and accept the delivery result; and the server notifies the packet sender to complete information, and pays the fee with the packet sender and the packet receiver. According to the flexible and controllable workflow management method provided by the invention, a standardized and normalized business process is formed in a self-control design work process, and rapid delivery is ensured.

Owner:上海夫卡实业发展有限公司

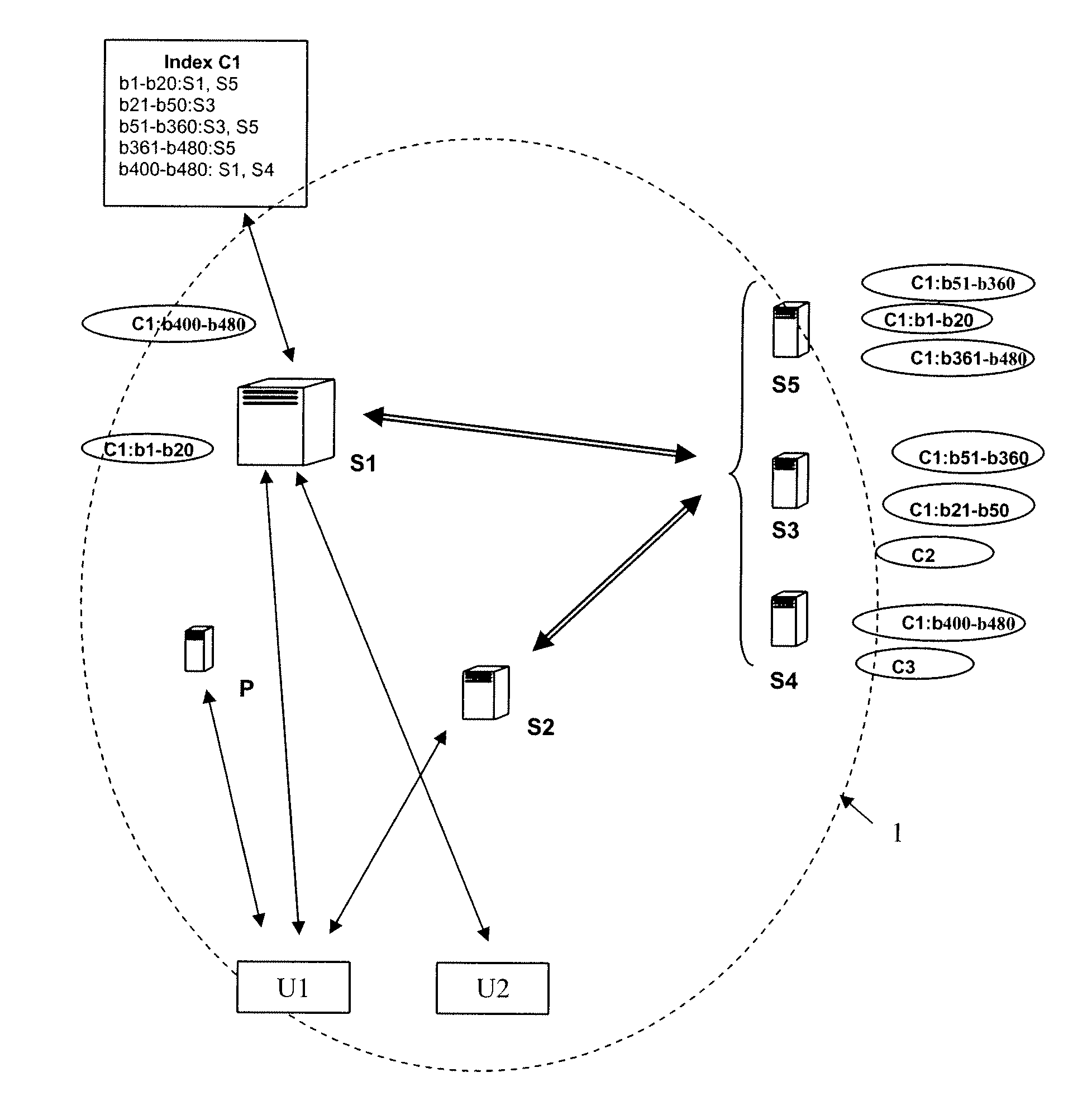

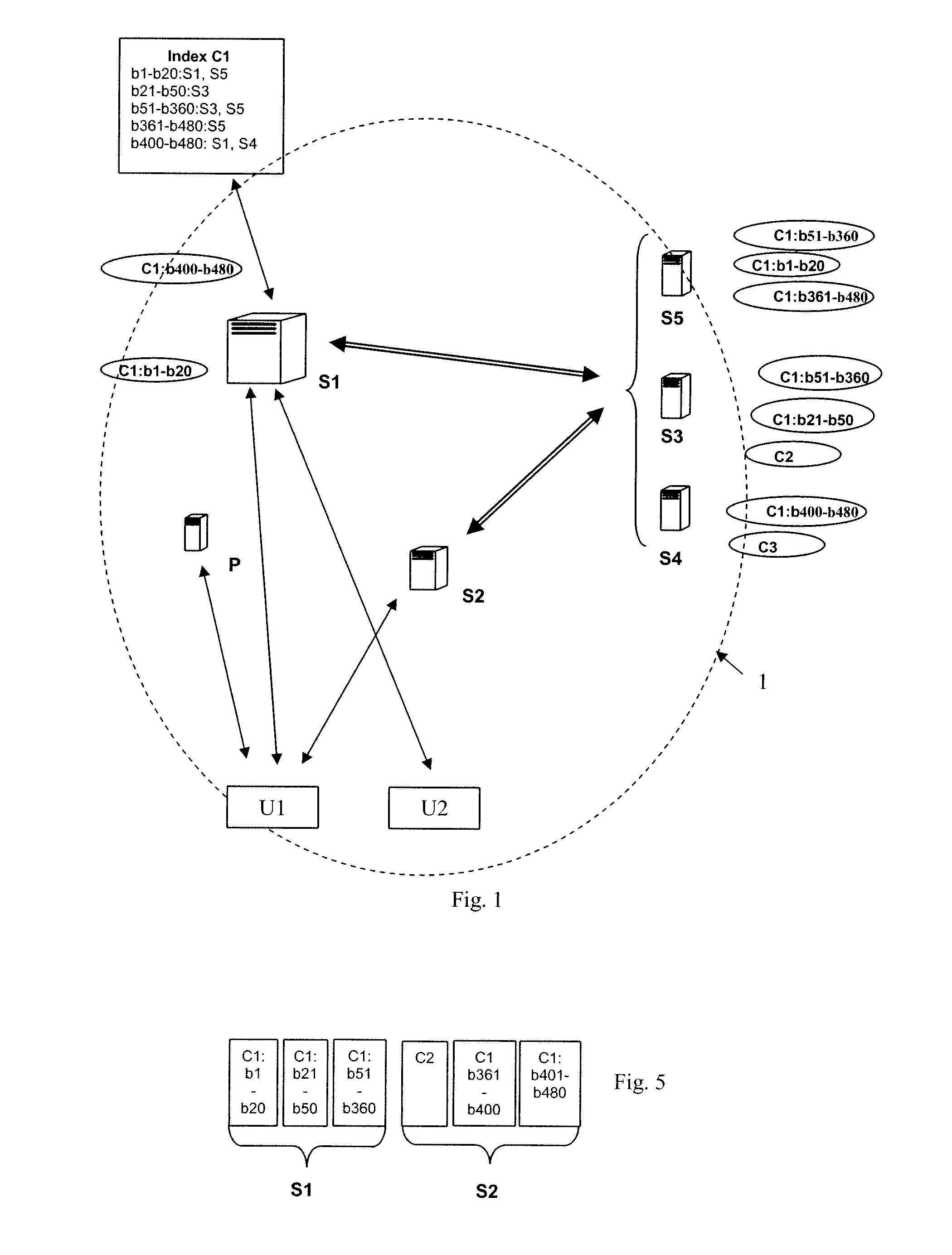

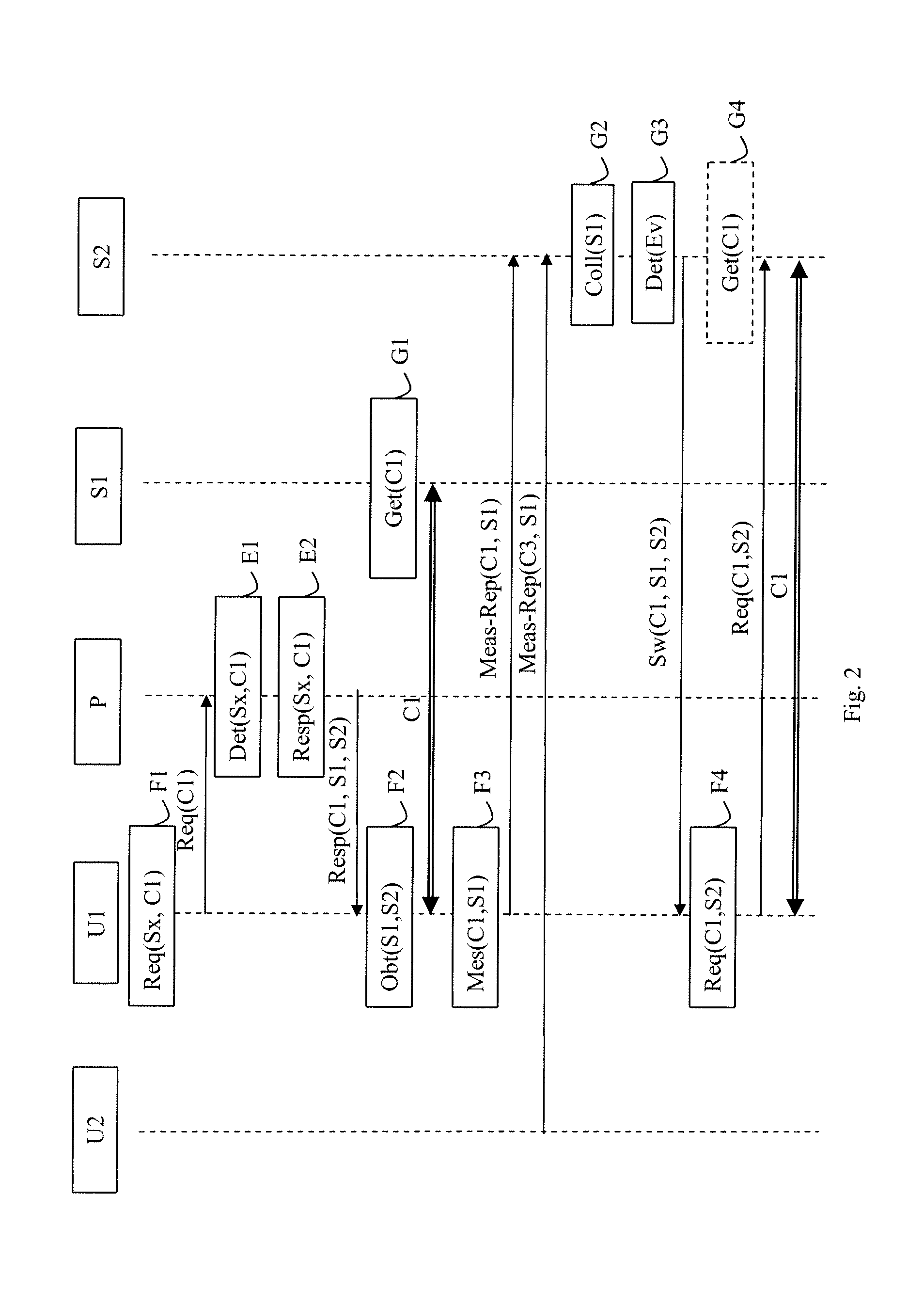

Technique for delivering content to a user

InactiveUS20120072604A1Drop in qualityQuality improvementMultiple digital computer combinationsTransmissionContent deliveryWorld Wide Web

Owner:FRANCE TELECOM SA

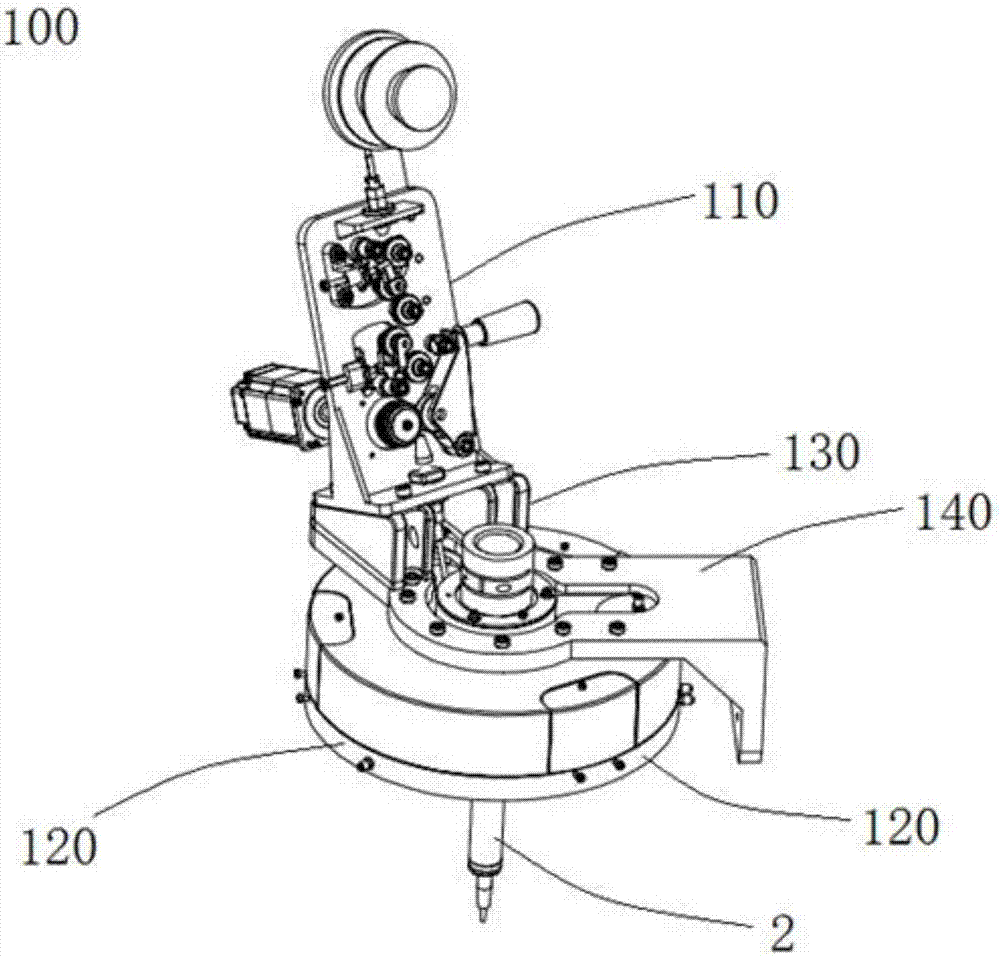

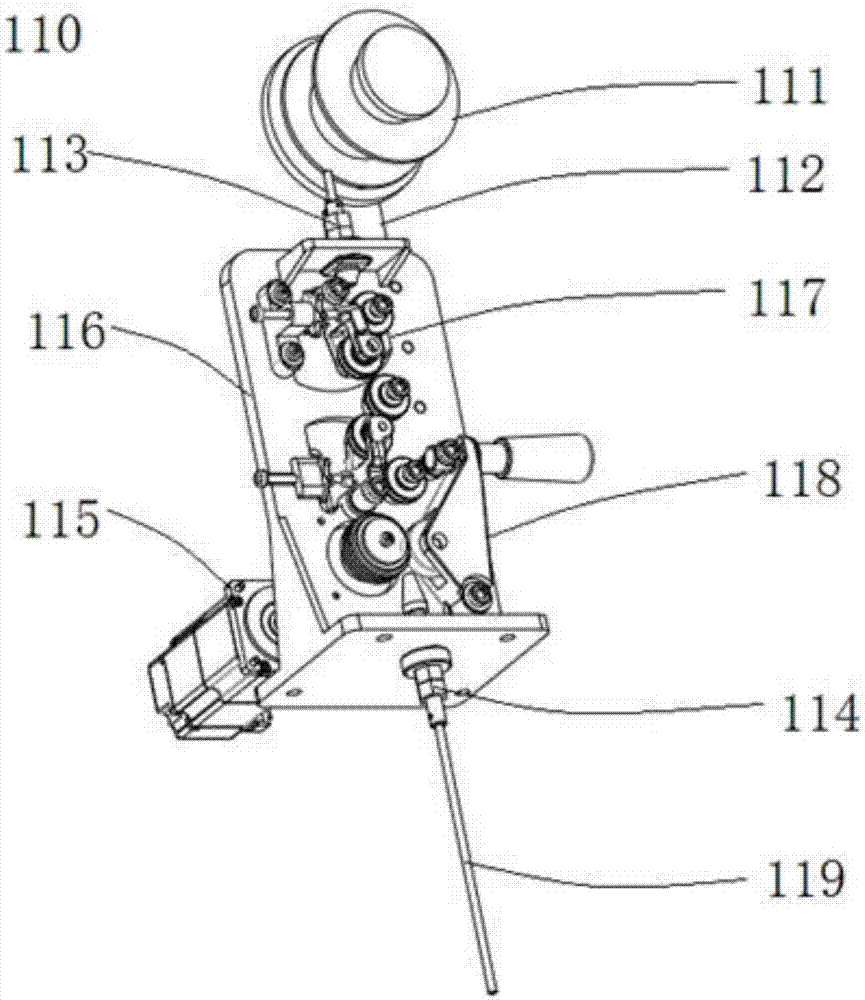

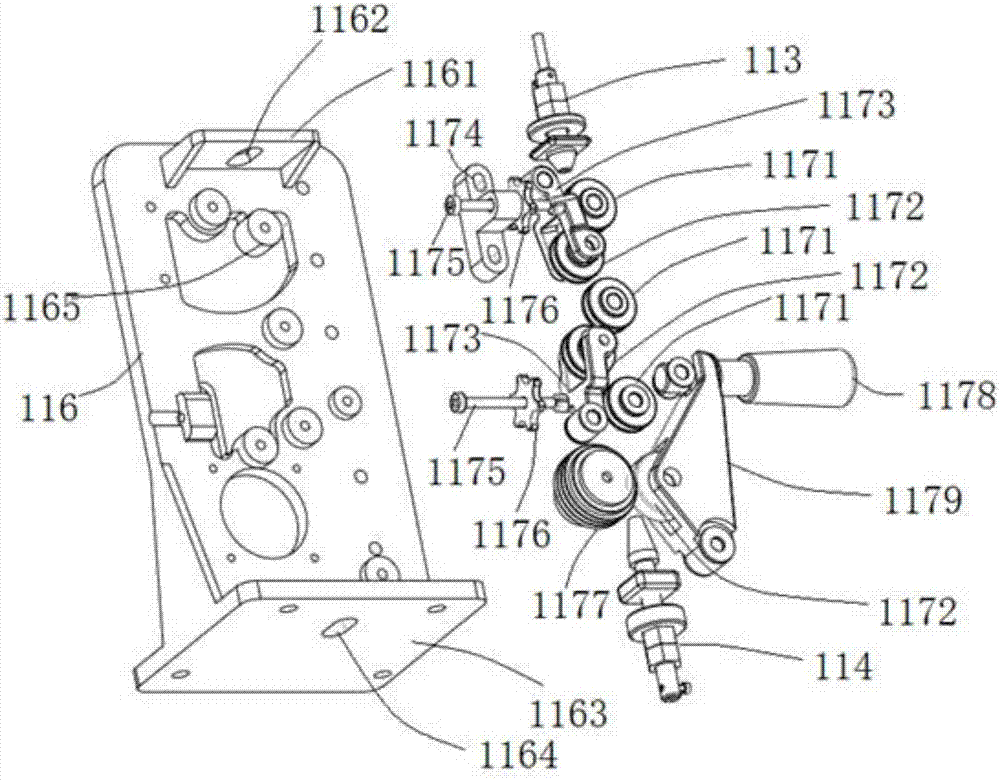

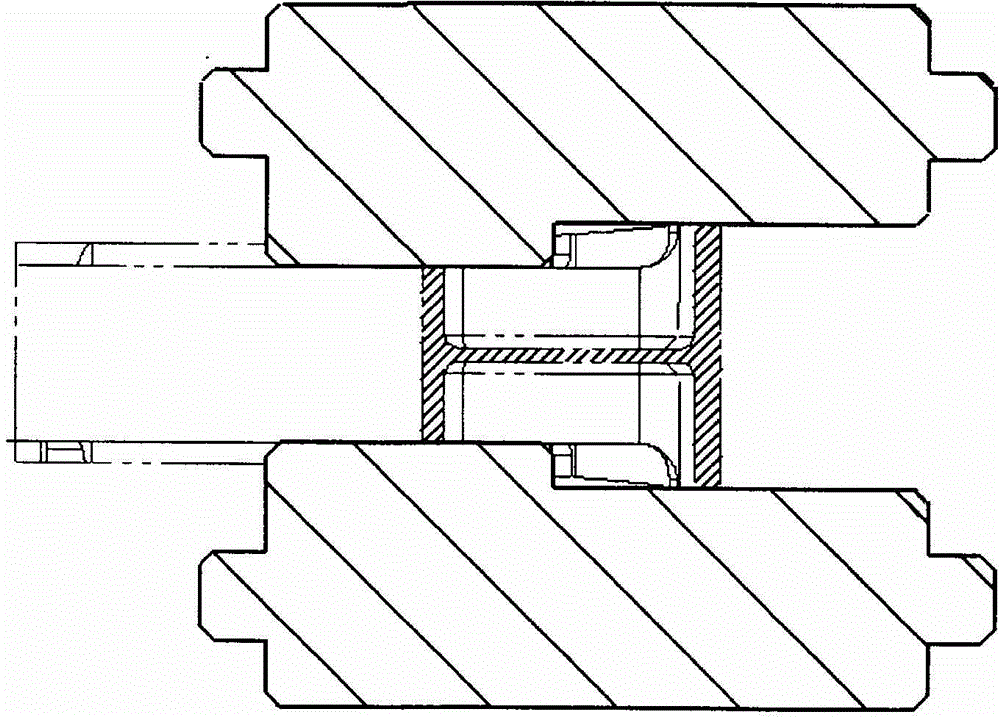

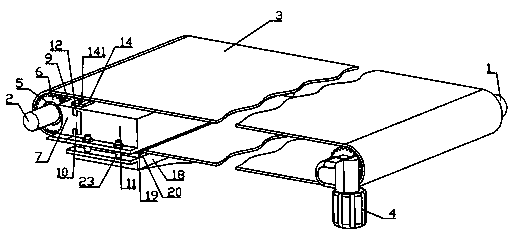

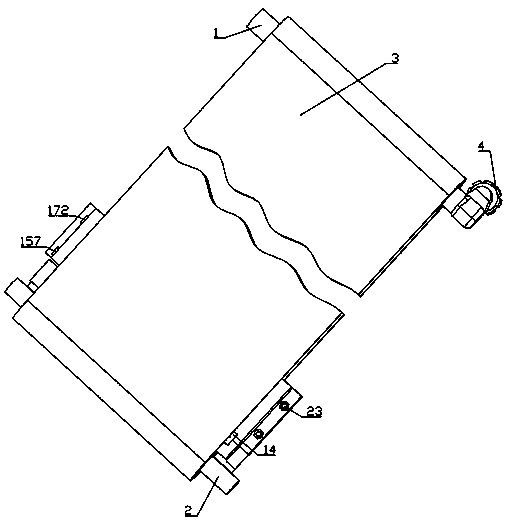

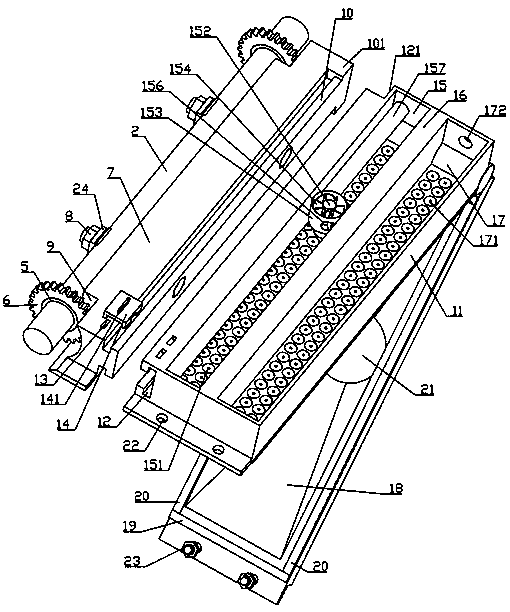

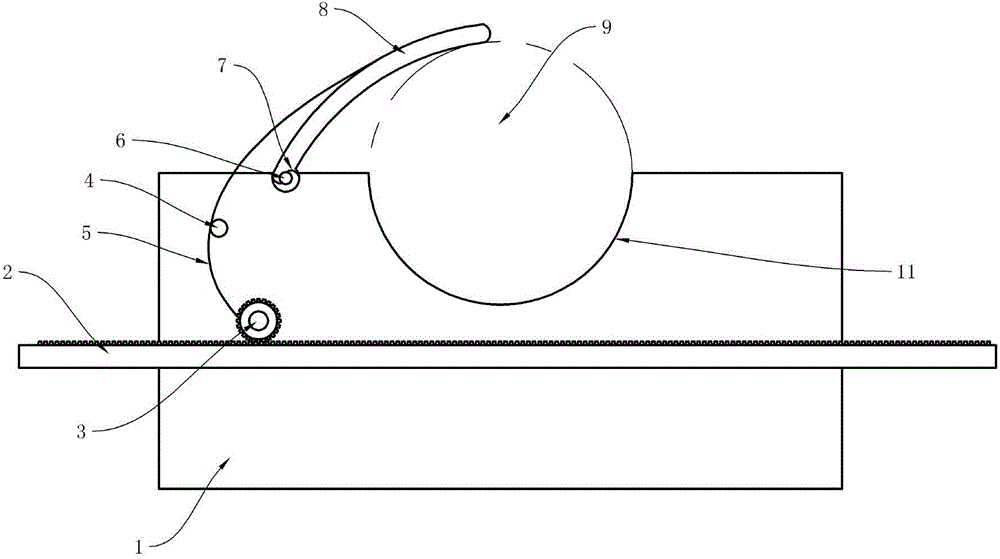

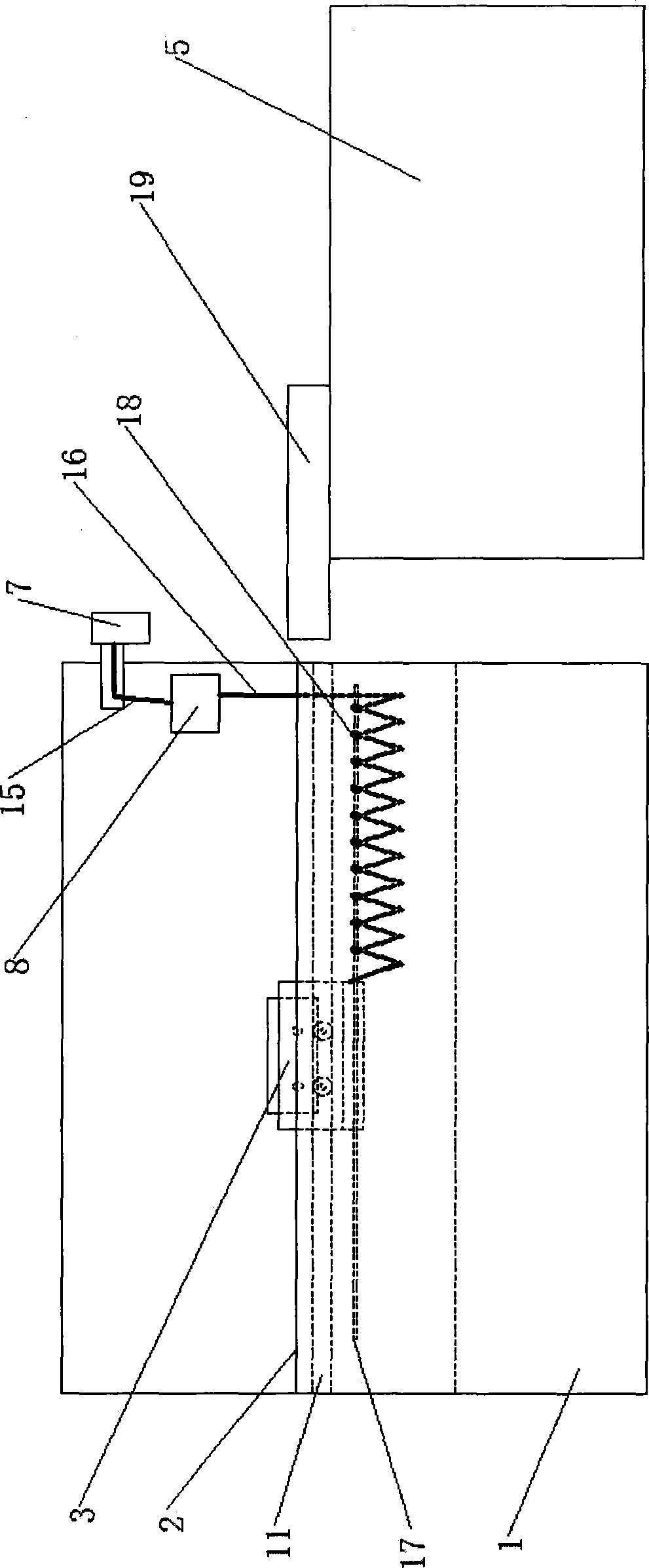

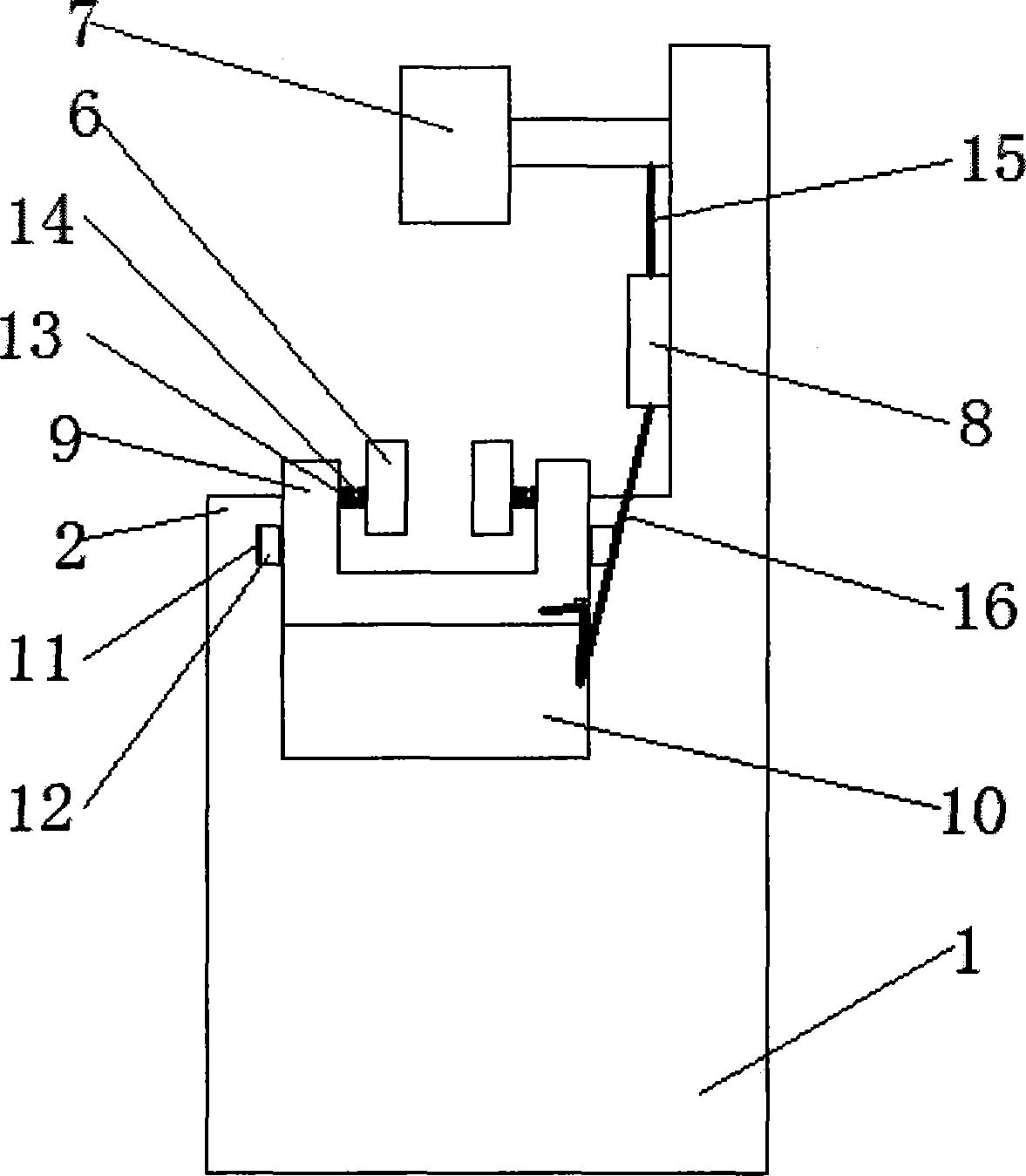

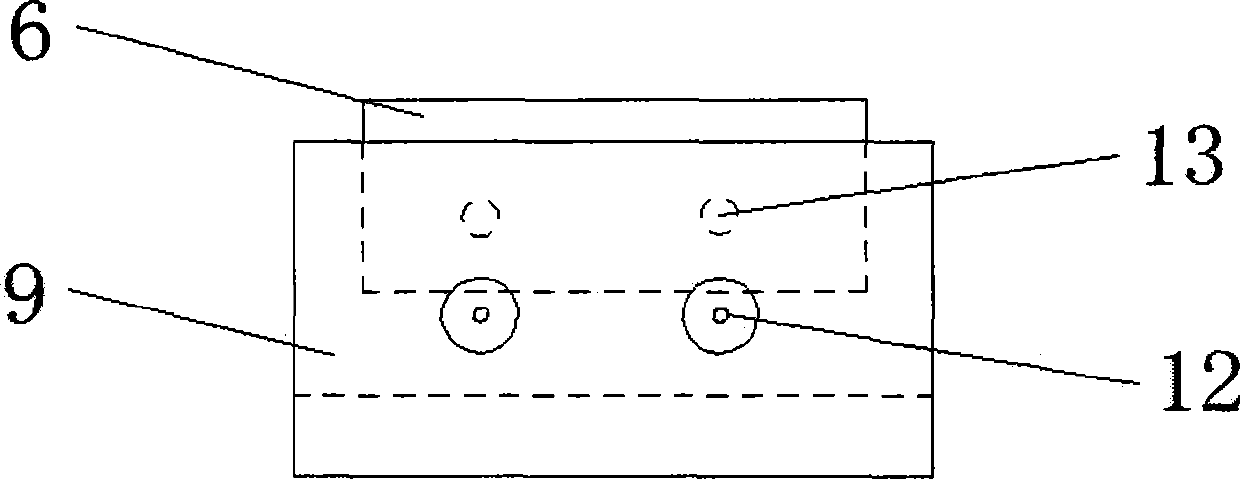

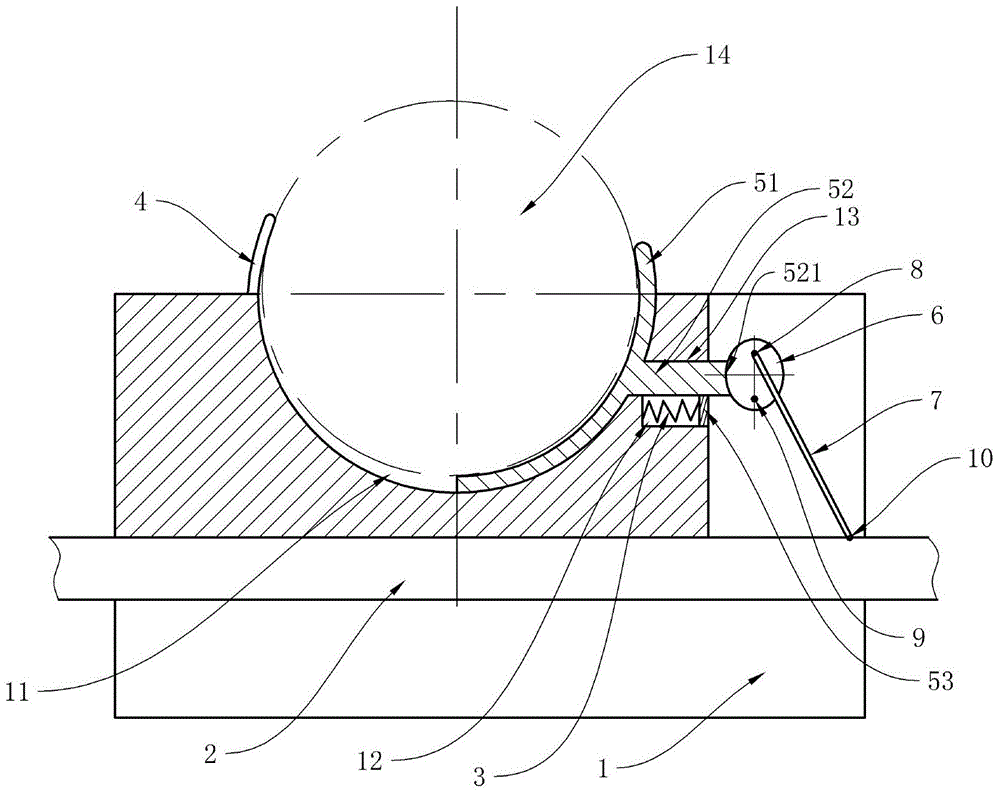

Wire feeder and laser cladding device

ActiveCN107414305AStraighter effect is obviousThe correction effect is even and smoothIncreasing energy efficiencyLaser beam welding apparatusDrive wheelGuide wires

The invention provides a wire feeder and a laser cladding device. The wire feeder comprises a bearing part, a straightening structure and a wire feeding structure, and further comprises a wire disc bracket and a wire disc arranged on the wire disc bracket, wherein the straightening structure and the wire feeding structure are arranged on the bearing part; the wire feeding structure comprises a drive structure, a drive wheel and a regulating structure; the drive structure is arranged on the bearing part and is connected with the drive wheel; the regulating structure is matched with the drive wheel to press a wire. The invention also provides a laser cladding device using the wire feeder. The wire feeder further comprises an adjustable wire guide nozzle structure arranged on the bearing part, and a slide wheel structure with a V-shaped slot; and the wire guide slot of the active wheel can be regulated to realize transmission of wires of different specifications, so that wire transmission stability is guaranteed, and high-precision cladding shape and dimension precision are guaranteed.

Owner:SUZHOU UNIV

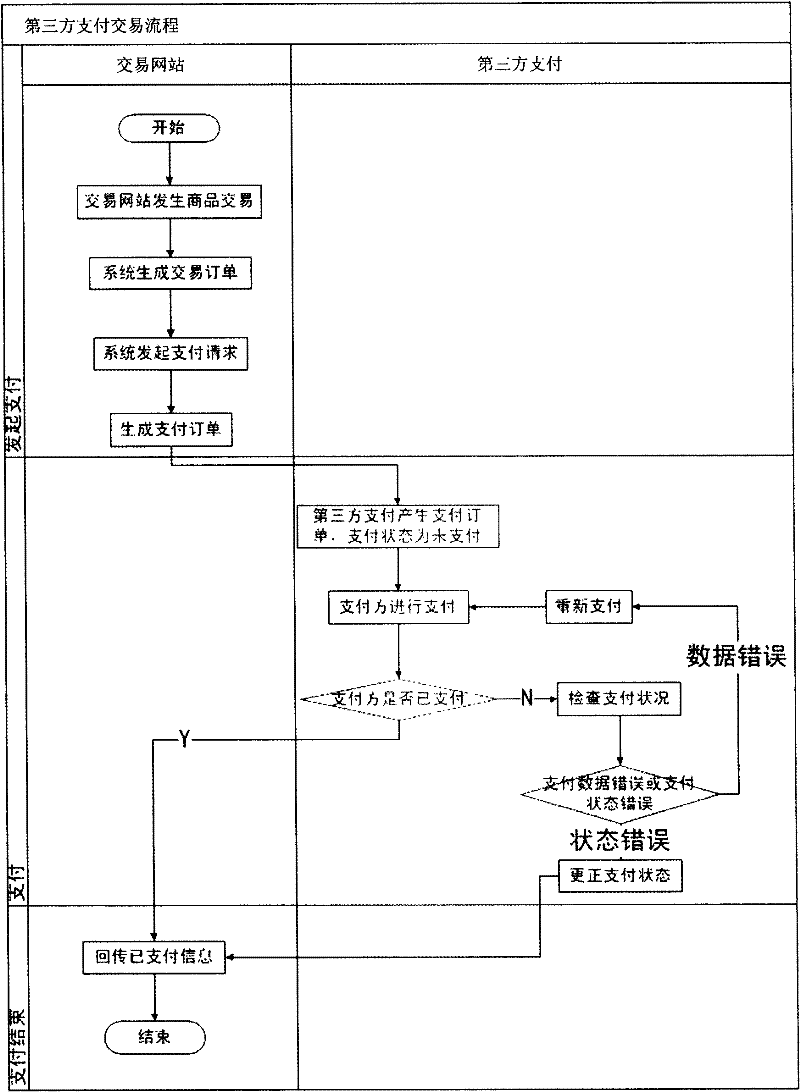

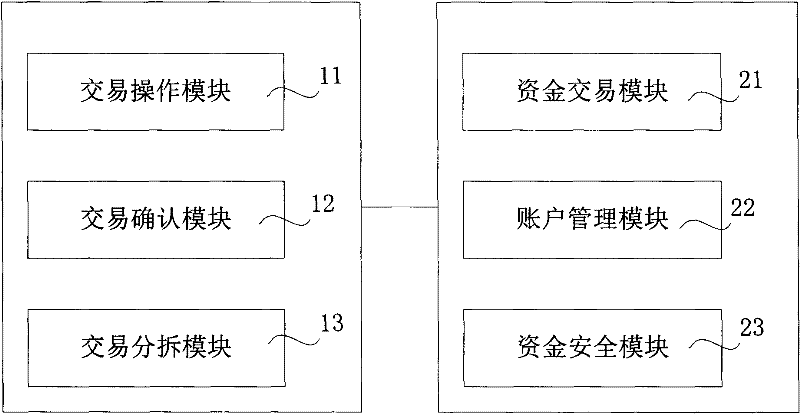

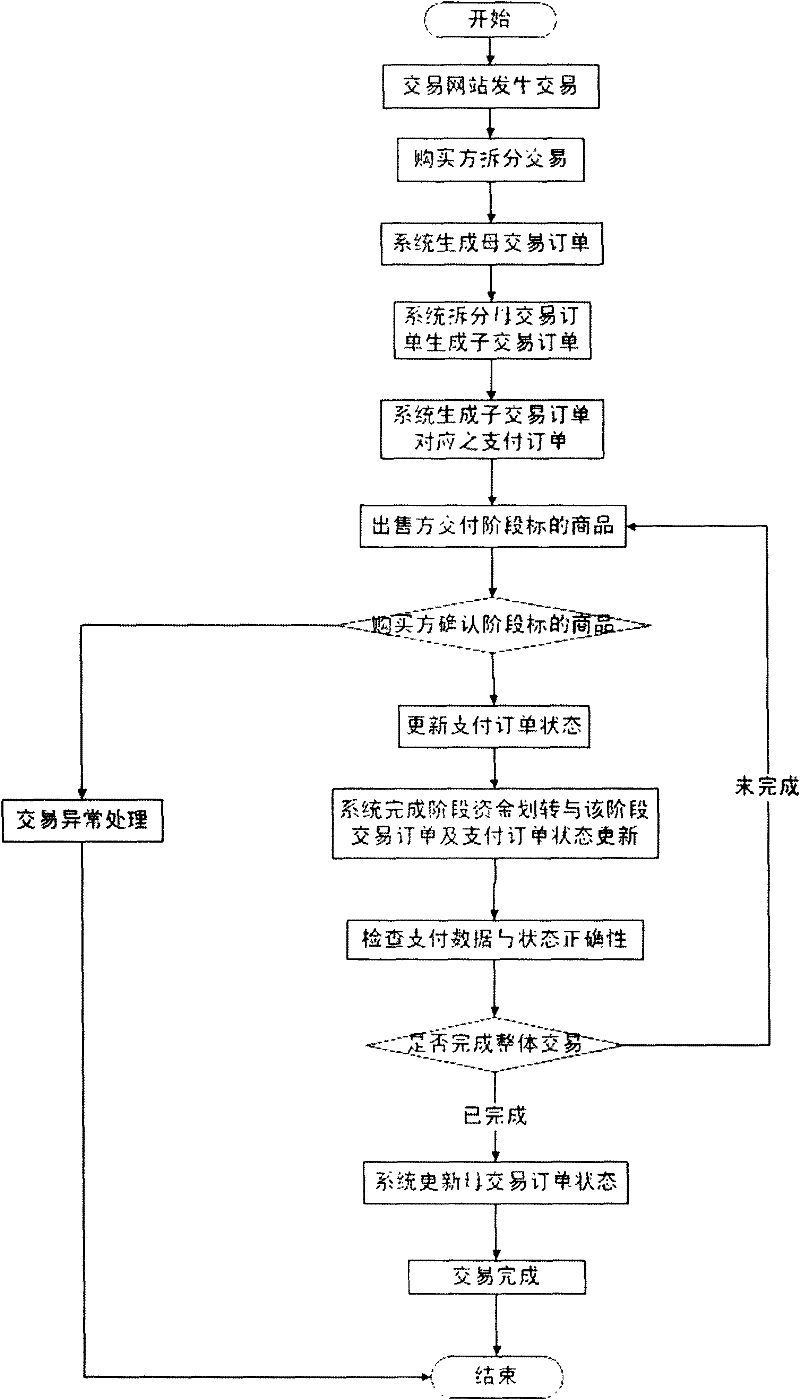

Network transaction system and method

InactiveCN102339446AGuaranteed delivery qualityImprove transaction satisfactionCommercePaymentOperating system

The invention discloses a network transaction system and method. The system comprises a transaction partitioning module and a fund transaction module, wherein the transaction partitioning module is used for partitioning a whole transaction into a plurality of stage tasks and setting completion criteria of each task and updating the step state according to the complete condition of each step; the fund transaction module is used for setting corresponding payment amount according to the stage tasks partitioned by the transaction partitioning module, carrying out fund locking and freezing in the process of executing each step and carrying out step-by-step payment according to the step state at the current stage; and the payment is carried out according to the importance and value of each stage task, so that the fund safety is ensured. The network transaction system and method disclosed by the invention have the capabilities of enhancing project progress control and ensuring that online transaction is carried out according to given time and progress.

Owner:陈晓亮

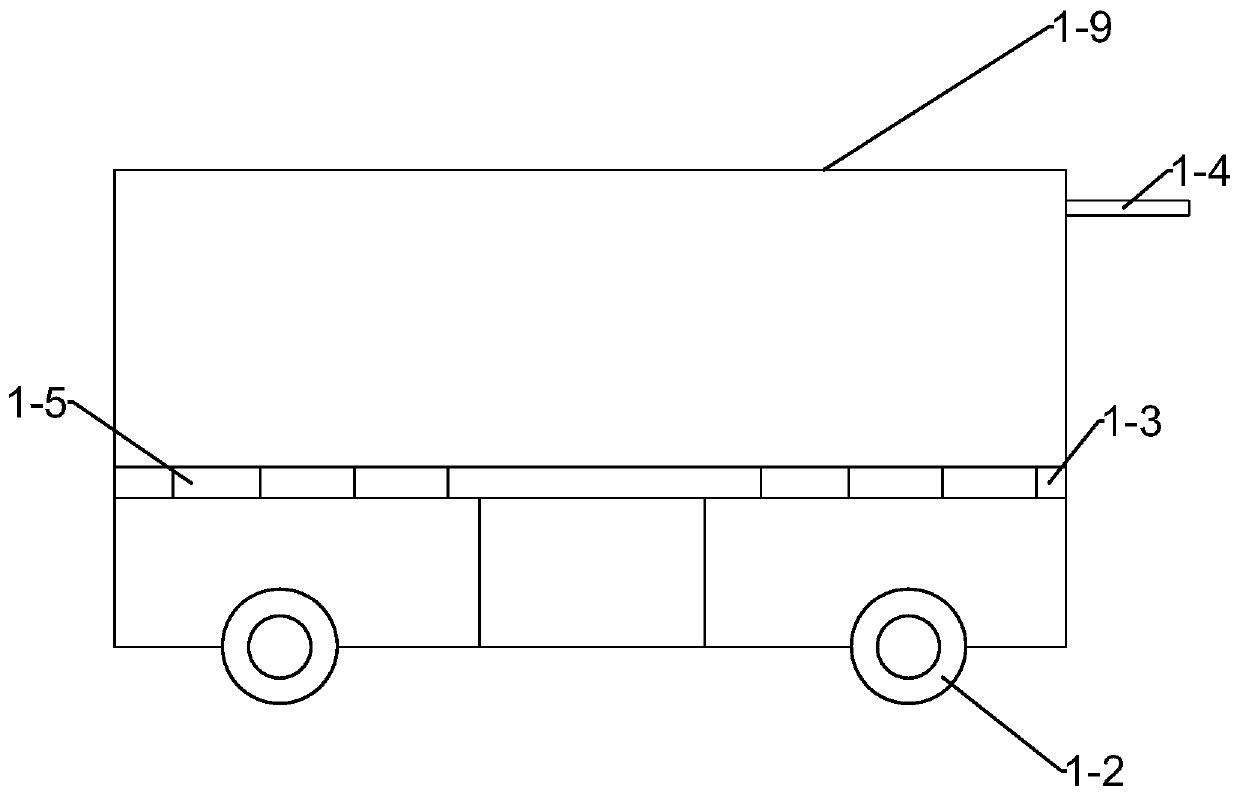

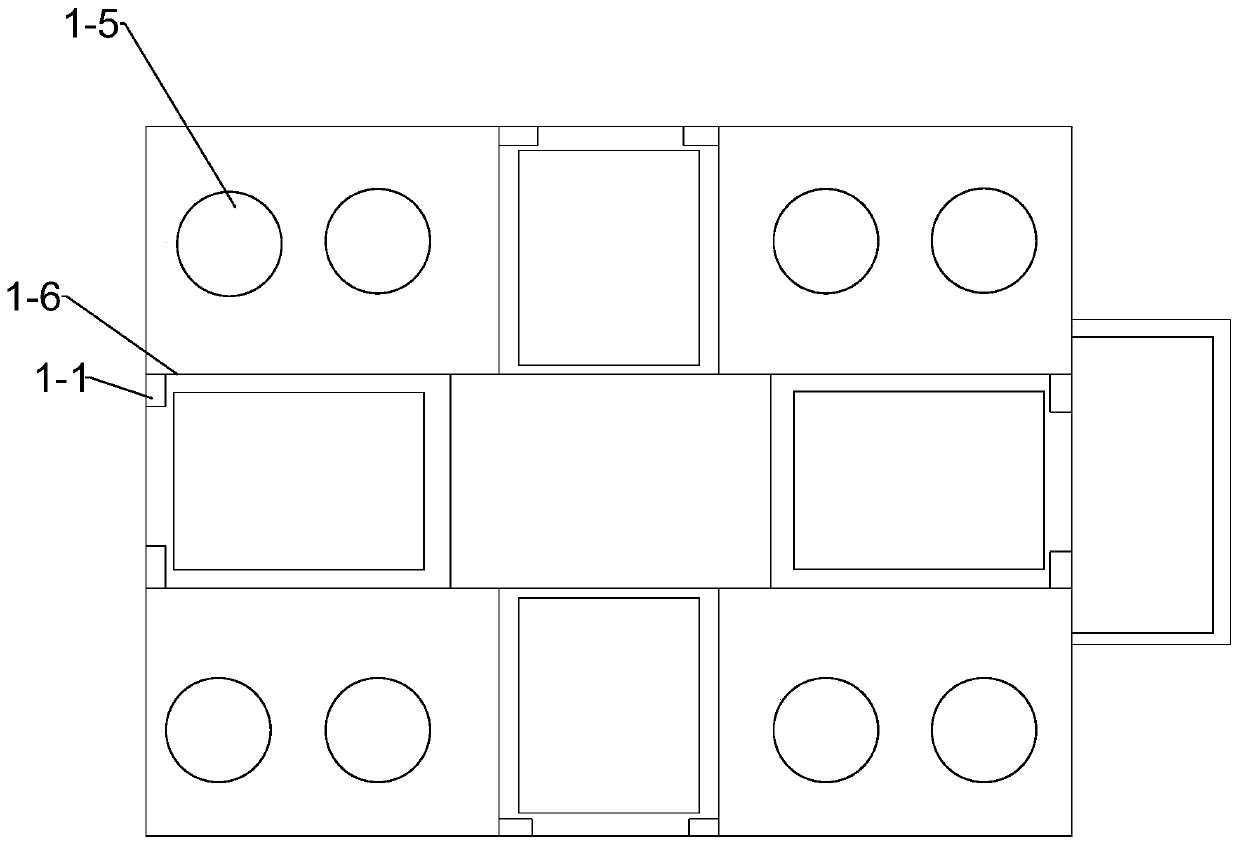

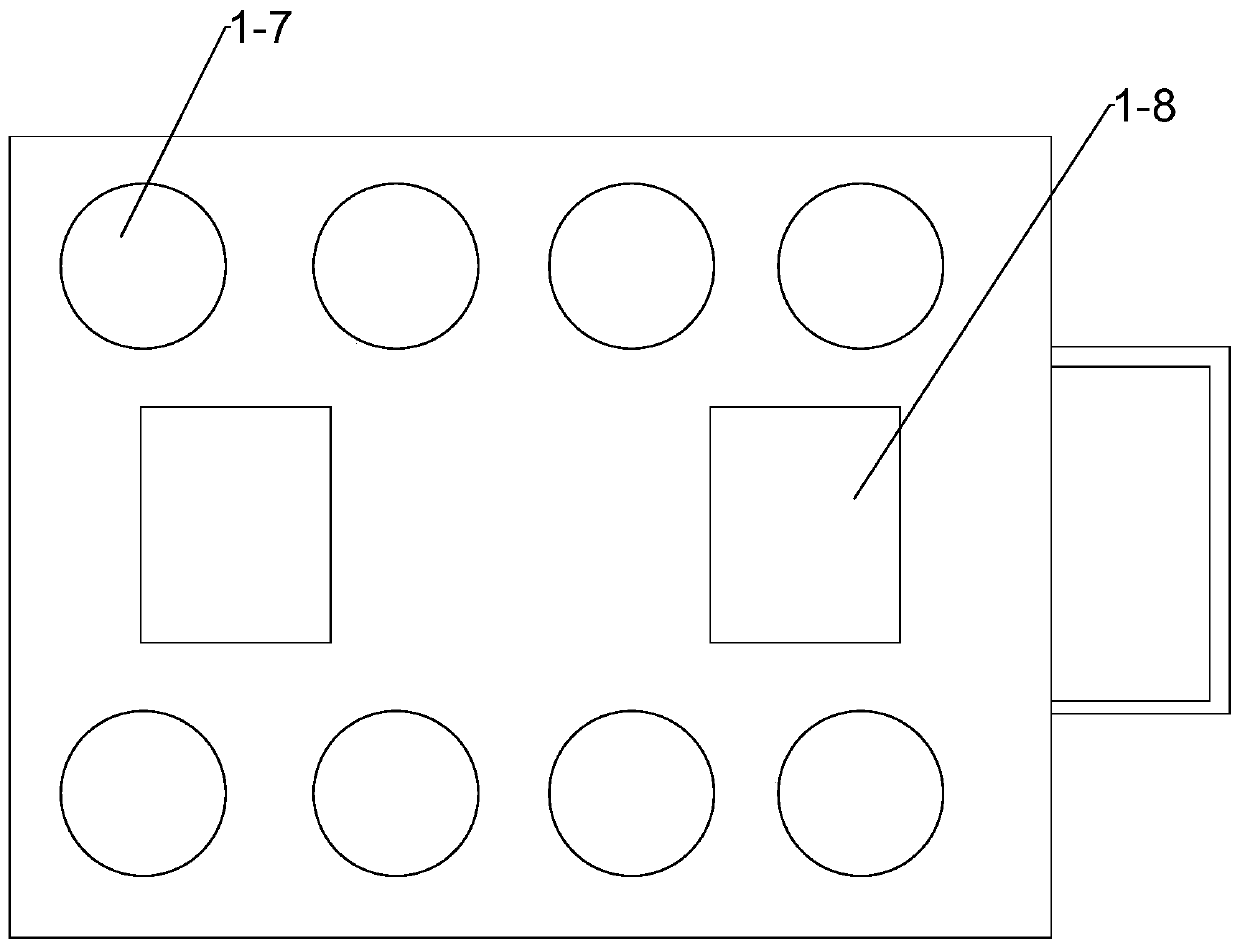

Microbial specimen preservation and conveying device

InactiveCN109823666AQuick collectionImprove survival rateLiving organism packagingDomestic cooling apparatusEngineeringBio-Specimen

The invention discloses a microbial specimen preservation and conveying device which comprises a double-layer preservation and conveying frame, a non-corrosion-resistant microbial specimen conveying and preservation container, a direct culture medium cultured microbial specimen conveying and preservation container, an anaerobic conveying culture medium microbial specimen conveying and preservationcontainer and an aerobic conveying culture medium microbial specimen preservation container; the transverse center and the longitudinal center of the lower-layer preservation and conveying frame of the double-layer preservation and conveying frame are provided with anaerobic conveying culture medium microbial specimen conveying and preservation container channels respectively; a sliding rail is arranged in each anaerobic conveying culture medium microbial specimen conveying and preservation container channel; and the ends of the sliding rails are provided with switches respectively. By adopting the microbial specimen preservation and conveying device, microbial specimen can be placed in specimen preservation containers with different storage conditions in a classifying manner, so that medical workers can quickly collect and convey specimens, the survival rate of the specimens is high, and pain of the patients caused by sampling again is relieved.

Owner:漯河市第一人民医院

Method for heat treatment of large-sized titanium alloy frame parts by virtue of special-shaped blocks

The invention relates to a method for heat treatment of large-sized titanium alloy frame parts by virtue of special-shaped blocks. The method comprises the following steps: 1) processing a plurality of special-shaped blocks; 2) carrying out heat treatment by virtue of a titanium alloy vacuum annealing heat treatment furnace with a flat furnace bottom plate; 3) carrying out surface state inspection on the parts before the parts are charged into the furnace and cleaning the parts and the special-shaped blocks with alcohol or acetone, when the parts are charged into the furnace, arranging one end having a plane of each special-shaped block on the furnace bottom plate of the vacuum heat treatment furnace, flatwise placing the parts on the laid special-shaped blocks according to the order-difference corresponding relationship, placing special-shaped blocks having corresponding sizes to the parts on the parts and positioning and then carrying out vacuum stabilizing annealing heat treatment; and 4) heating the parts by virtue of heating steps so as to ensure that the parts are evenly heated during heating for the annealing heat treatment. By the method, the deformation of the parts is effectively controlled, the accurate control of the sizes of the parts is achieved, the stabilizing heat treatment of the parts is ensured, the delivery quality of the parts is guaranteed and meanwhile, the production efficiency is increased.

Owner:SHENYANG AIRCRAFT CORP

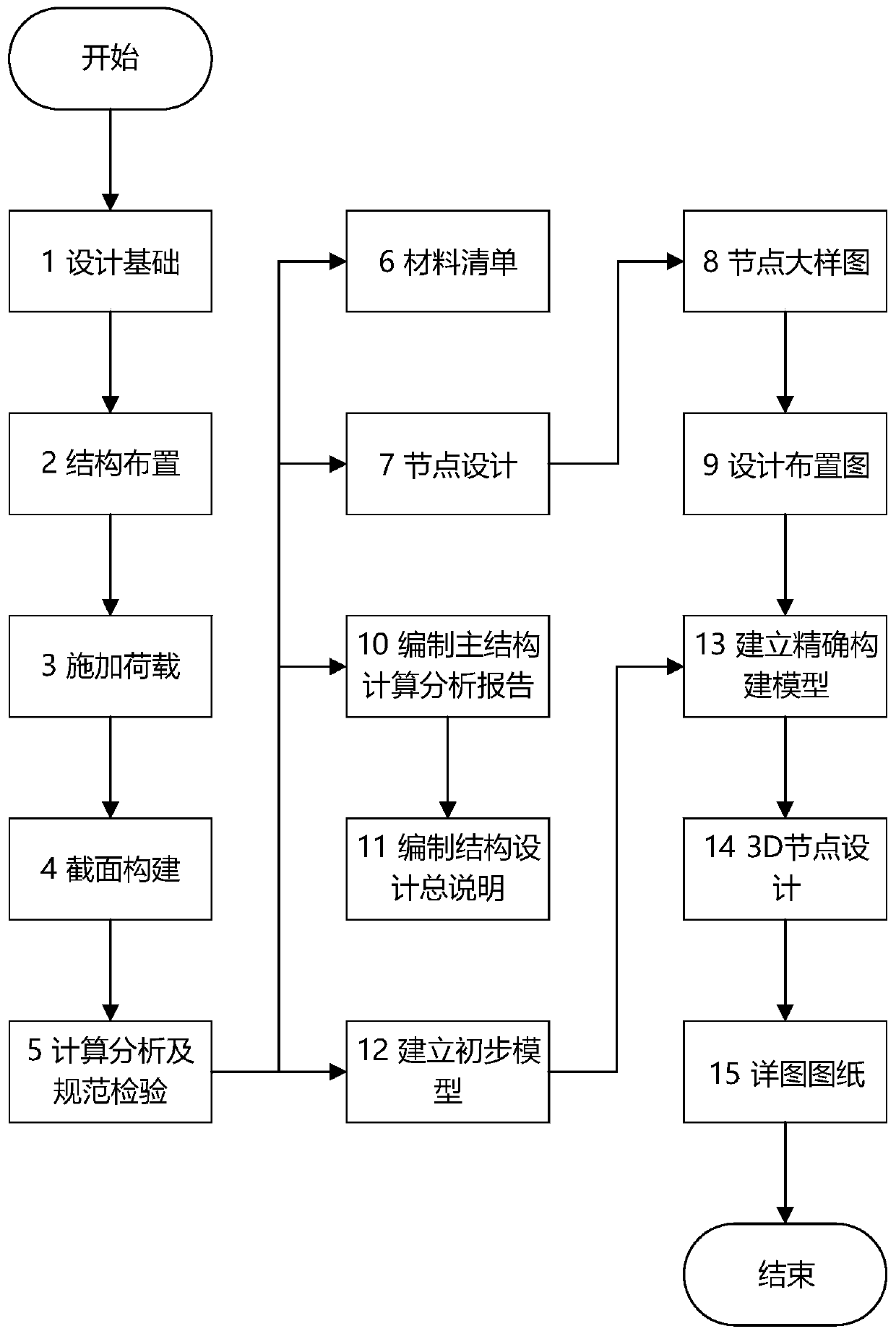

Rapid delivery structure design work management method, platform and system

The invention discloses a rapid delivery structure design work management method, platform and system. The method comprises the steps that a packet receiver registers a personal account and registerspersonal technical attribute information; the packet sender issues a structural design project demand and hosts project cost; the server establishes a project workflow and a task group according to structural design project requirements; the server executes the workflow and sends the sub-tasks in the task group to a user terminal of a packet receiver conforming to the technical attribute of the sub-tasks; the packet receiver sends an instruction of subtask application; the packet receiver completes task uploading and delivery results within the task deadline; the server notifies the packet sender to check and accept the delivery result; and the server integrates delivery results of all the task groups, informs the packet sender of finishing information, and pays the cost according to the workload of the finished sub-tasks, the packet sender and the packet receiver. According to the flexible and controllable workflow management method provided by the invention, the process of structuredesign work forms a standardized and normalized business process, and rapid delivery is ensured.

Owner:上海夫卡实业发展有限公司

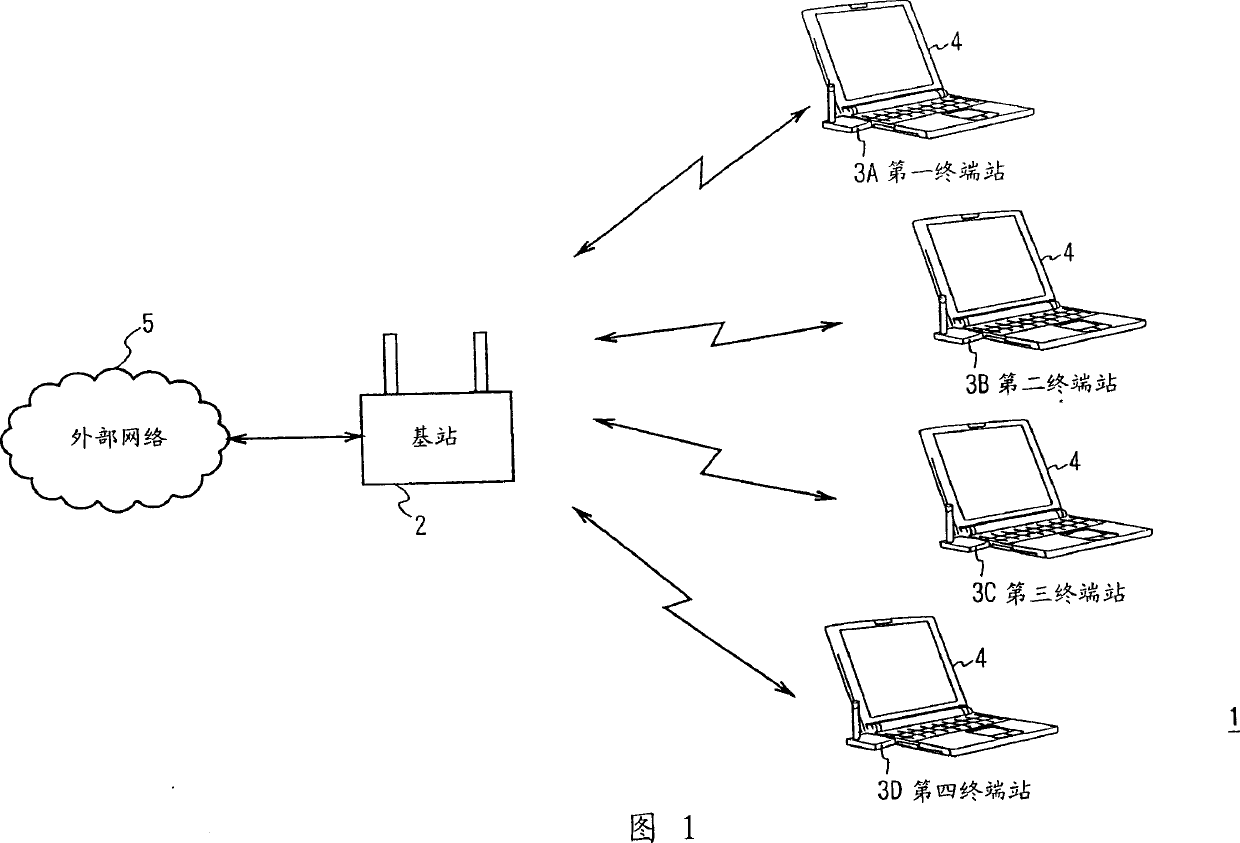

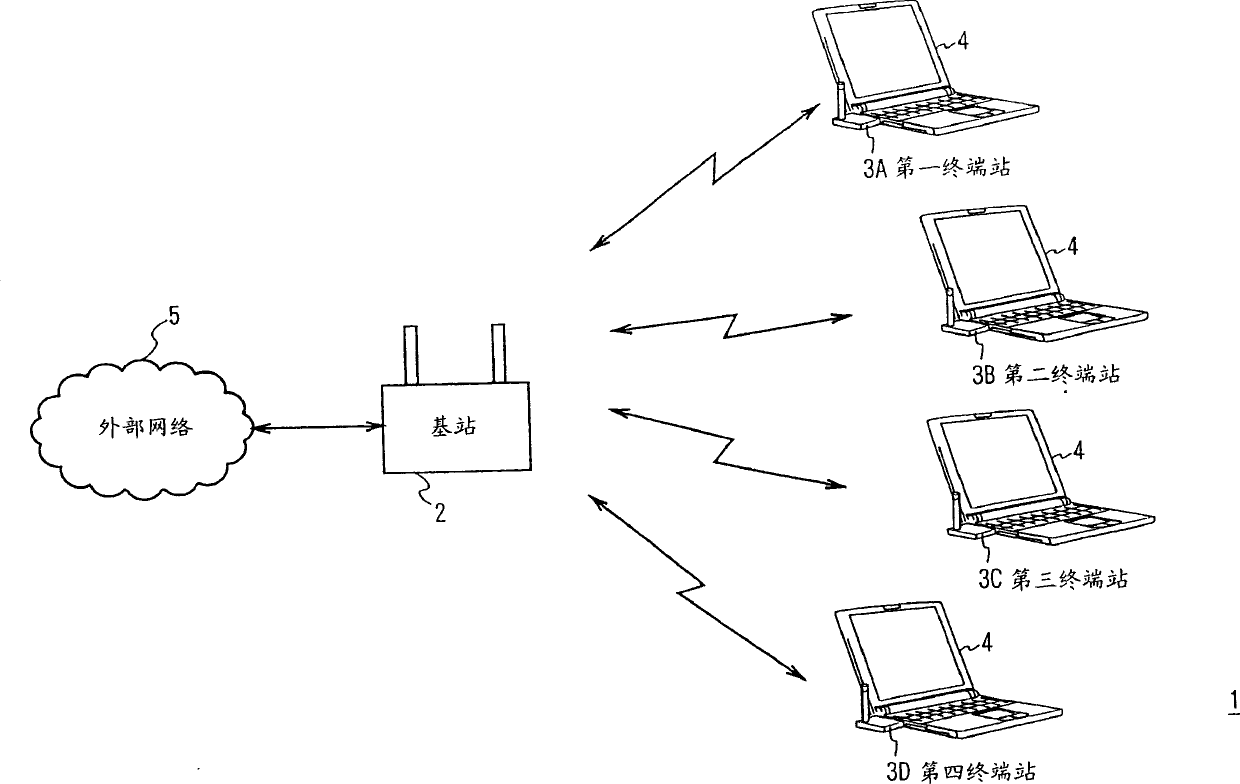

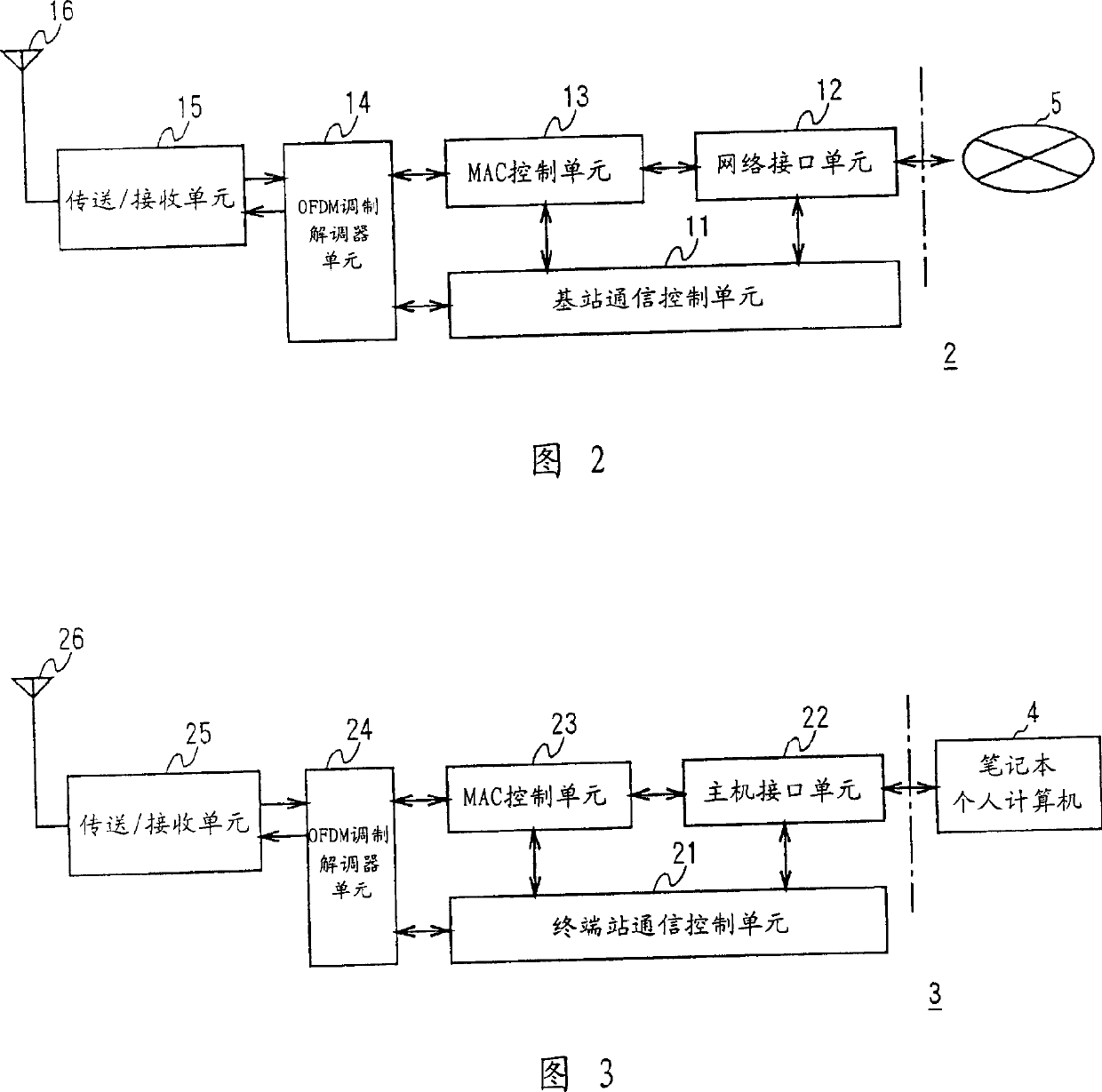

Radio communication system

InactiveCN1701564AAvoid overlappingGuaranteed fixed beacon intervalSynchronisation arrangementAssess restrictionCommunications systemTerminal equipment

To realize a wireless communication system capable of keeping a beacon interval fixed, keeping transmission quality, and performing intermittence reception without fail. A wireless communication management device includes and transmits beacon time period information in a main beacon and a sub beacon. Then, a wireless terminal device divides transmission data based on the beacon time period information so that the transmission of the transmission data is finished before the transmission of a main beacon is started. Thereby, overlap of transmission timings of the beacon and the transmission data can be prevented and the beacon interval can be made fixed. This can keep transmission quality, makes the wireless terminal device to perform intermittence reception without fail, and improve the entire data transmission efficiency of the system.

Owner:SONY GRP CORP

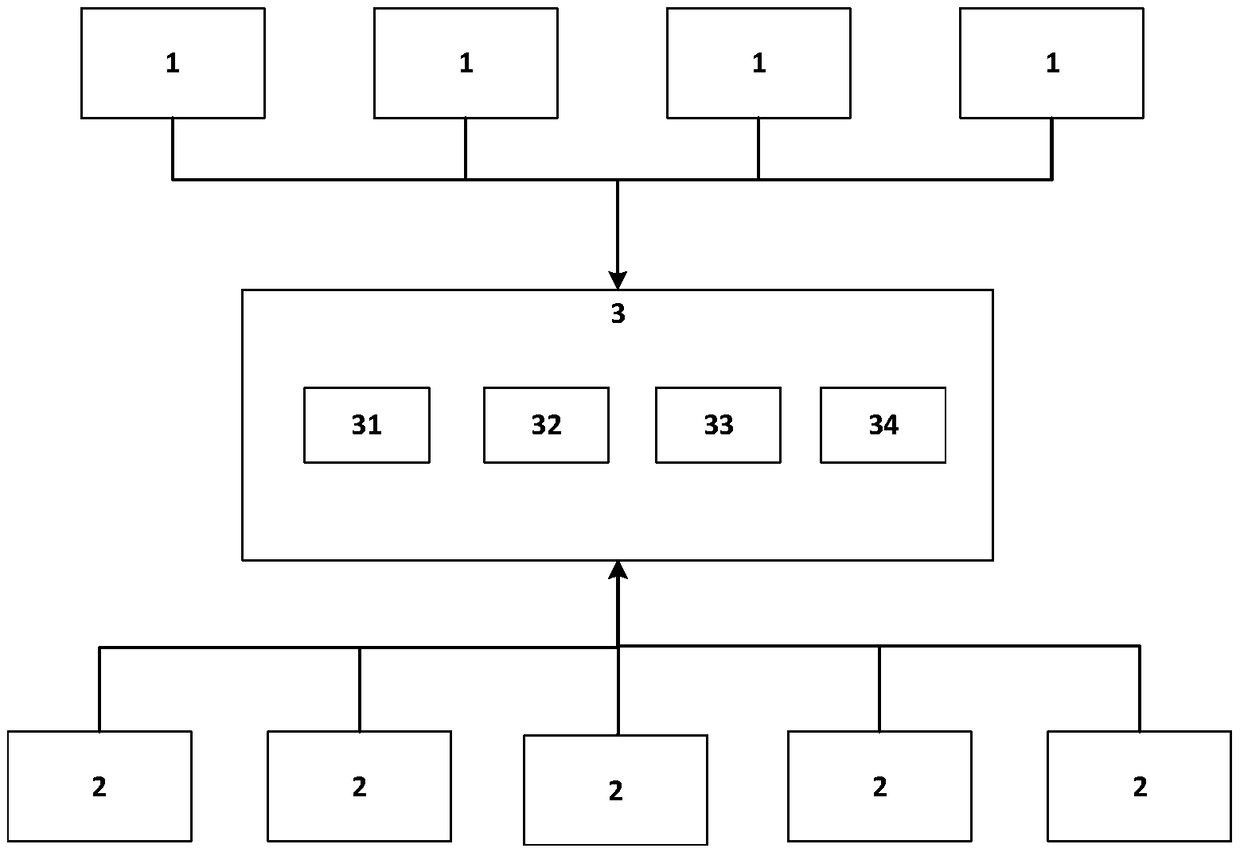

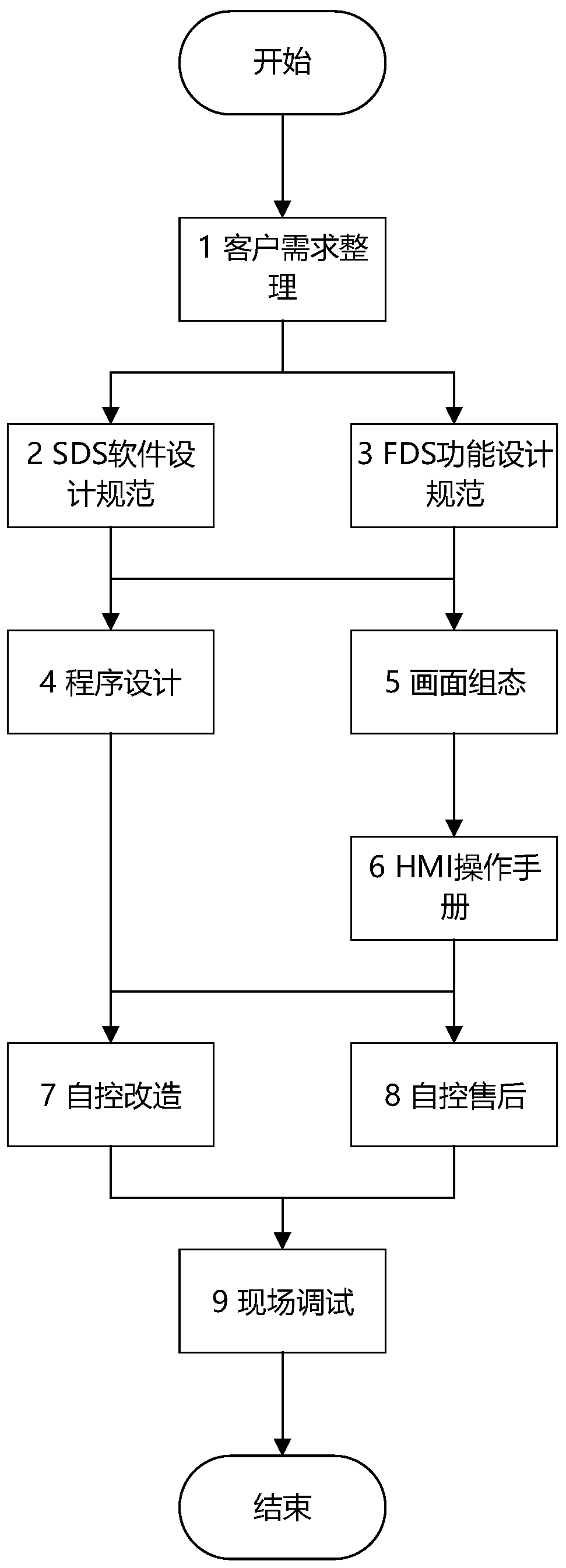

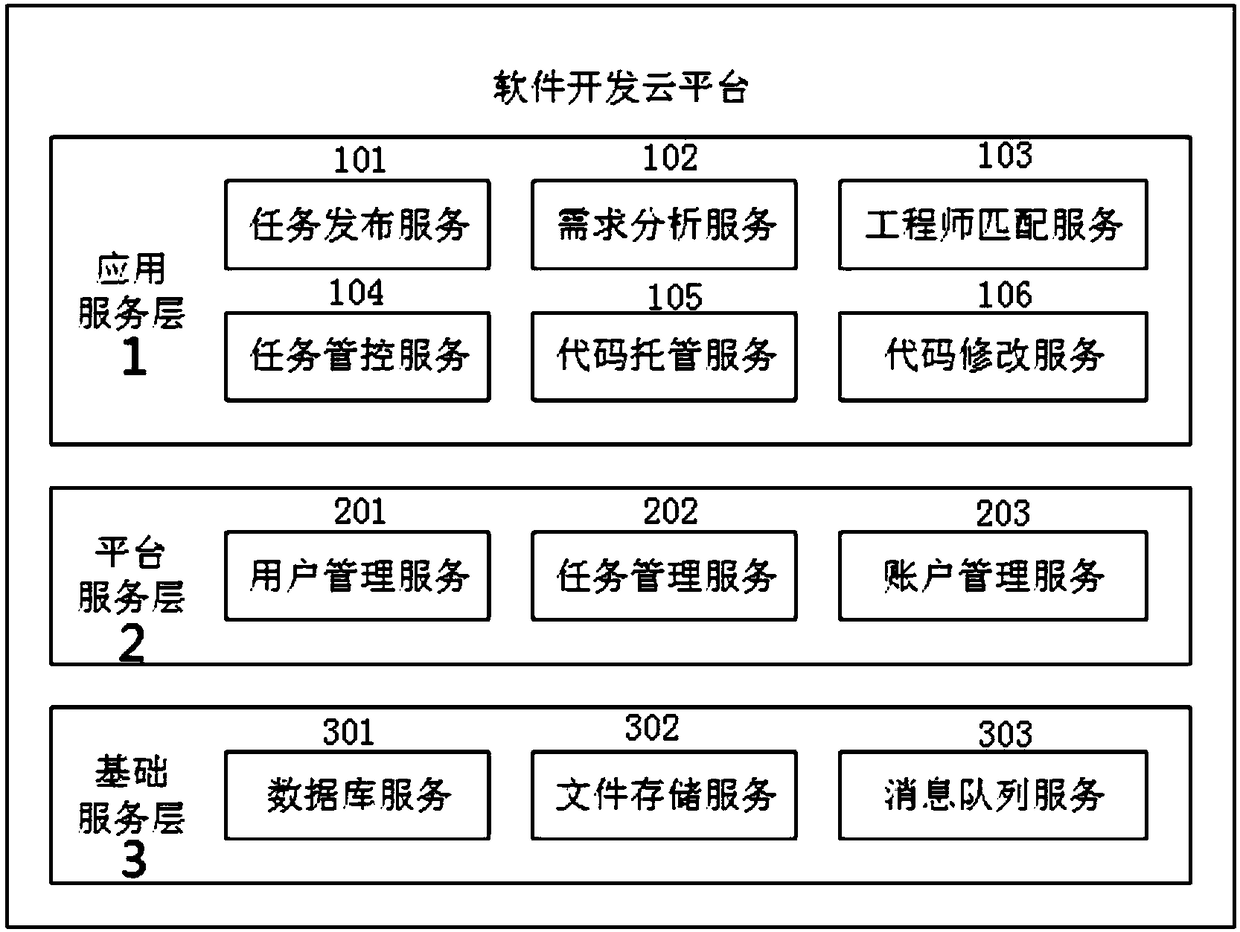

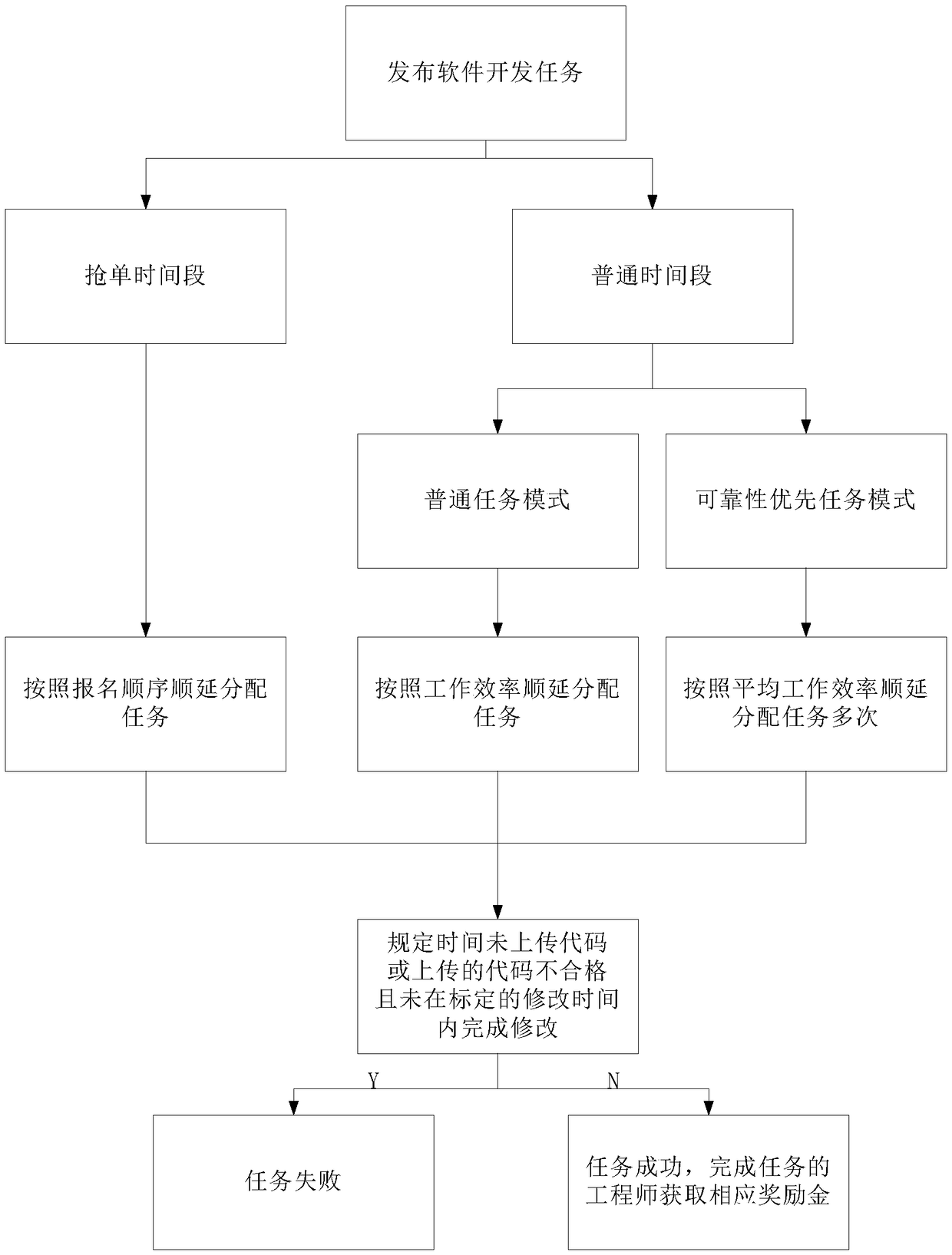

Software development cloud platform based on different time periods and different distribution mechanisms

InactiveCN109034610AShorten delivery timeReduce communication workloadSoftware designResourcesSoftware development processComputer module

The invention relates to the technical field of computer application, in particular to a software development cloud platform based on different time periods and different distribution mechanisms. Theplatform comprises a plurality of functional modules encapsulated in the form of cloud service, wherein the functional modules are respectively arranged at the basic service layer, the platform service layer and the application service layer; The application service layer is used to provide business-based functional services, and calculate the development workload and overall development cost according to the software development requirements sent by customers, distrubte the software development requirement tasks according to the work efficiency of the engineer based on the development workload in the ordinary time period, during the period of order grabbing, distrubute the software development requirement tasks according to the order of engineer registration based on the development workload, receive the code completed by the software development, and initiate the customer expense settlement expense to the engineer user and the task according to the success or failure of the task. Theplatform uses standardized business processes to improve engineer collaborative development efficiency, ensure delivery quality, and ensure on-time delivery.

Owner:武汉空心科技有限公司

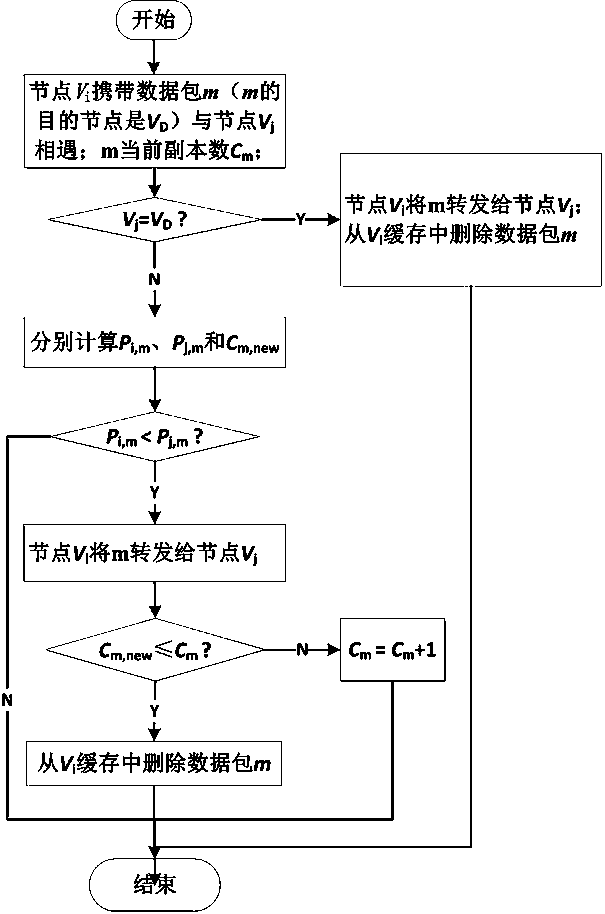

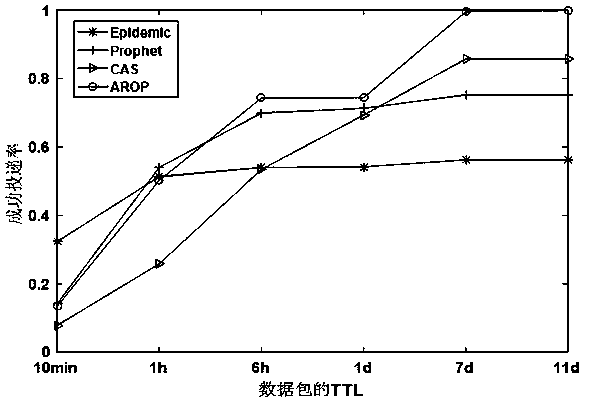

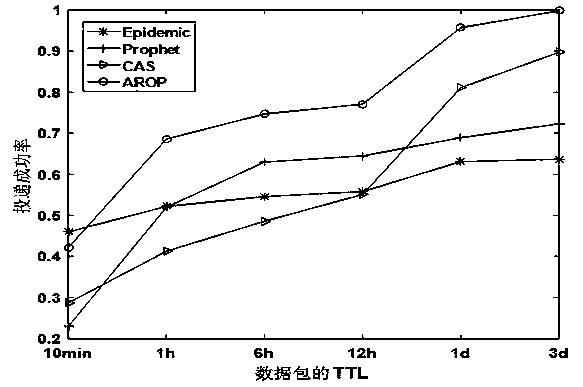

Opportunistic routing method based on delivery prediction and copy self-adaptation in opportunity network

InactiveCN110166292AReduce delivery costGuaranteed delivery qualityData switching networksDelivery costSelf adaptive

The invention discloses an opportunistic routing method based on delivery prediction and copy self-adaptation in an opportunity network. The opportunistic routing method comprises the following steps:S1, describing the opportunity network based on a symmetric weighted network diagram; S2, obtaining a utility function of the node for the data packet based on the symmetric weighted network diagramand the service life of the data packet; S3, the node judging whether the contact node is a destination node of the to-be-forwarded data packet in the moving process, if yes, directly forwarding the to-be-forwarded data packet, and deleting the locally cached to-be-forwarded data packet; S4, the node calculating a utility function value of the node to the to-be-forwarded data packet, a utility function value of the contact node to the to-be-forwarded data packet and a maximum allowable copy number of the to-be-forwarded data packet; S5, the node determining whether to forward the data packet to be forwarded to the contact node according to the utility function value; and S6, the node determining whether to continue to cache the to-be-forwarded data packet according to whether the backup number of the to-be-forwarded data packet in the current opportunity network reaches the maximum allowable copy number. The delivery cost can be reduced under the condition that the delivery quality isguaranteed.

Owner:HENAN UNIV OF SCI & TECH

Automatic equipment cleaning device

PendingCN111591720ARealize the effect of automatic cleaningSave human resourcesCleaningGear wheelElectric machinery

The invention discloses an automatic equipment cleaning device. The automatic equipment cleaning device comprises a driving roller, a driven roller and a chain conveyor belt, wherein the power end ofthe driving roller is connected with a motor, a bearing and a gear are installed on the driven roller, the driven roller is matched with a fixing block, the fixing block is provided with a fixing through hole and a fixing screw, the fixing block is provided with a receding arc-shaped groove and a T-shaped fixing block, the T-shaped fixing block is matched with a cleaning box, the cleaning box comprises a fixing groove and buckling grooves, the buckling grooves are matched with buckling blocks, the cleaning box comprises an air drying box, a separating block and a spraying box, the air drying box comprises an air outlet, a rotating shaft, an air box, fan blades, a cam, through holes and an air inlet pipe, the input end of the air inlet pipe is connected with a hot air blower, the separatingblock comprises a cross-shaped groove, a cross-shaped sliding block, a stopping table, a spring, an ejector rod and a U-shaped brush body, the spraying box comprises spraying holes and a water inlet,the input end of the water inlet is connected with a water supply device, and the cleaning box is hinged to a water receiving box, the water receiving box and the cleaning box are provided with limiting blocks and auxiliary brush bodies, and the output end of the water receiving box is provided with a drain hole, fixing holes and fastening screws.

Owner:GUANGDONG INST OF SCI & TECH

Rack clamping structure for half shaft

InactiveCN106144202AReduce bumpsGuaranteed delivery qualityPackaging vehiclesContainers for machinesTorsion springTorsional Forces

The invention discloses a rack clamping structure for a half shaft. The rack clamping structure comprises a base, wherein a semicircular installation groove is formed in the base, and the base is hinged with one end of a curved pressing plate through a first hinge at the left side of the installation groove; the other end of the curved pressing plate is connected with a pull rope, the pull rope is connected with a gear after passing through a wire guide groove, a pull plate is arranged below the gear, and a rack engaged with the gear is arranged on the pull plate; and a torsional spring is installed in the first hinge, and the torsional spring generates a torsional force enabling the curved pressing plate to rotate towards the installation groove. The rack clamping structure disclosed by the invention is simple in structure, convenient to use, and capable of effectively reducing bump of the half shaft due to loose fixation, thus ensuring transport quality for the half shaft.

Owner:CHONGQING JINYUHENG TECH

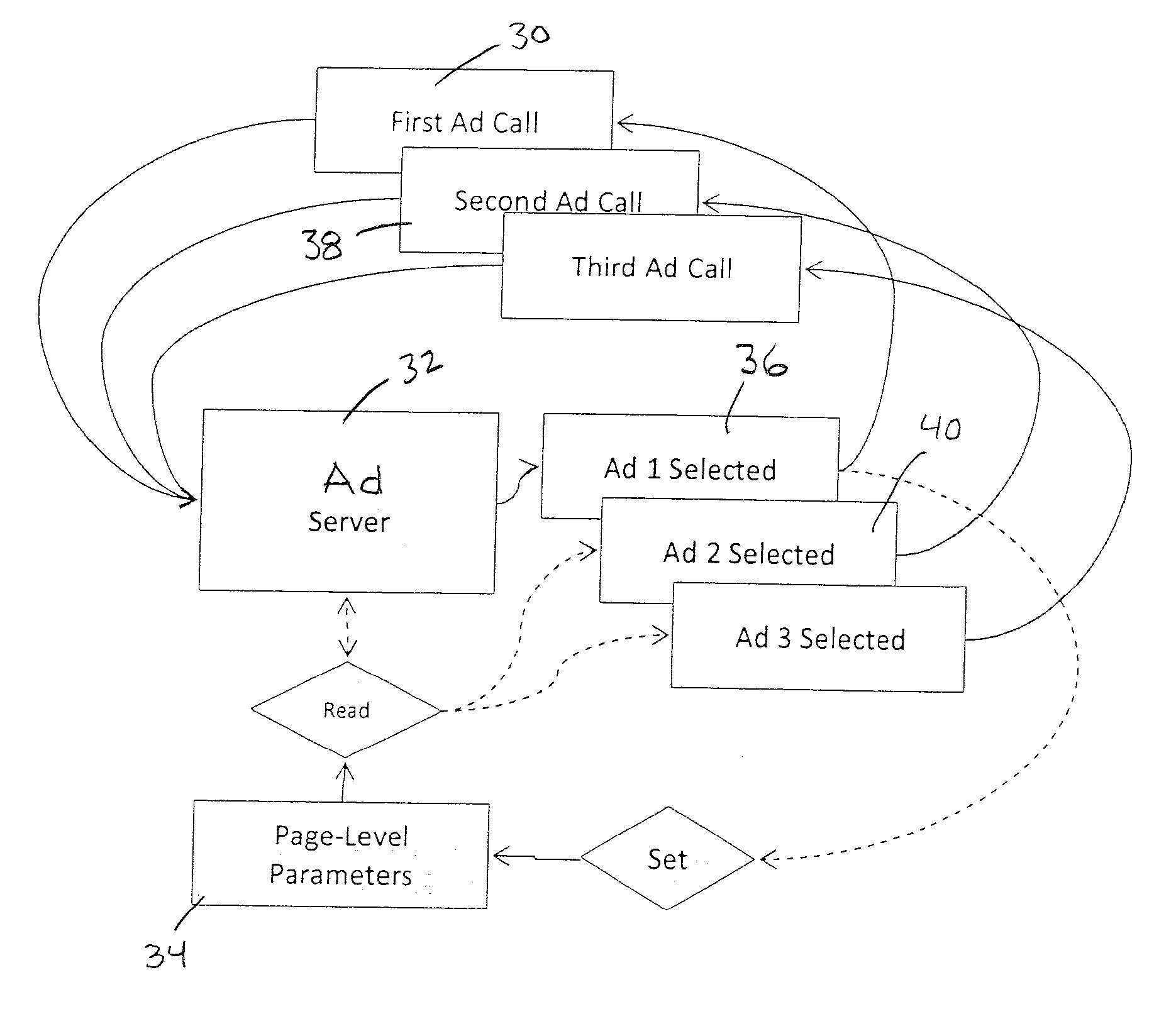

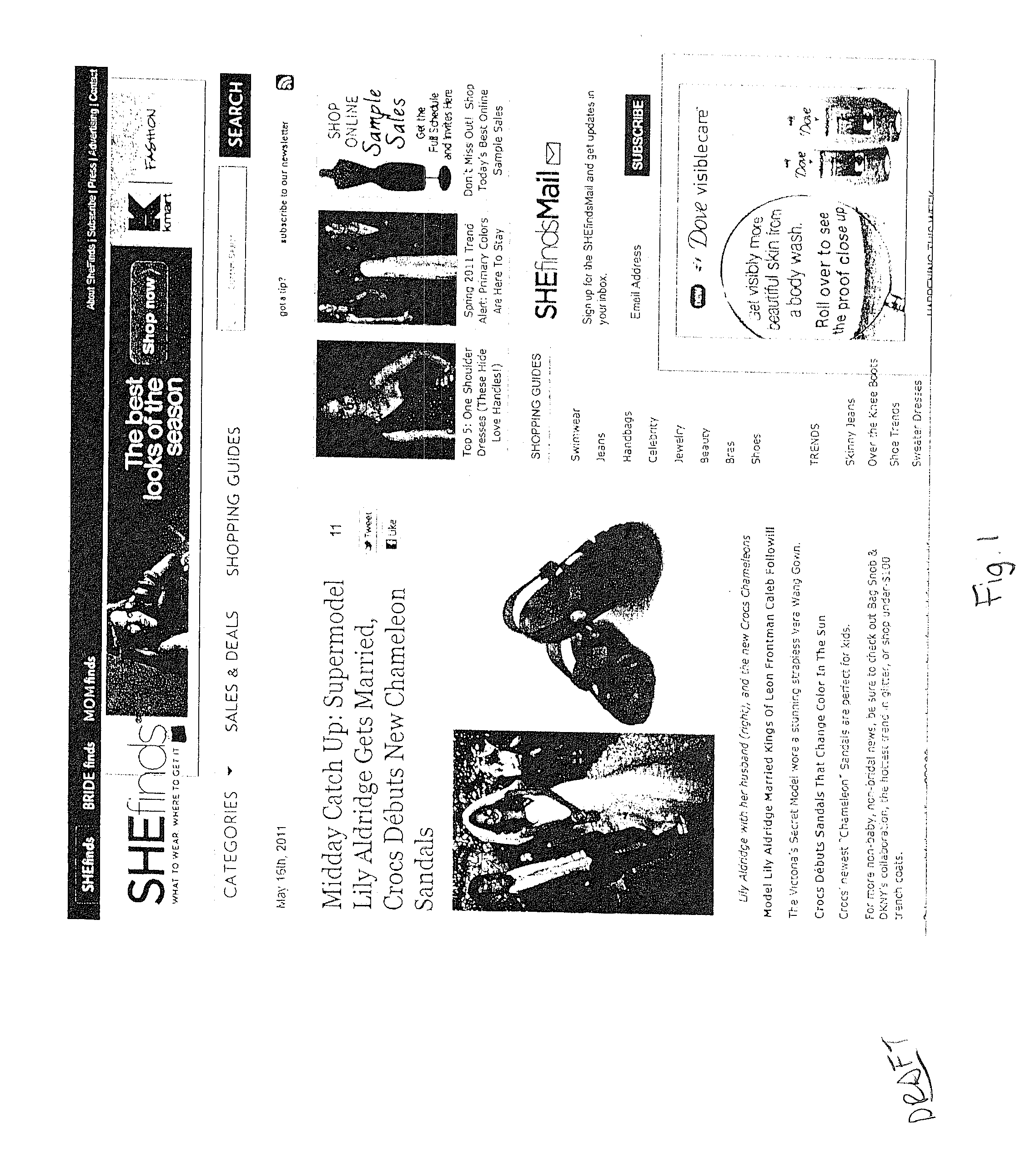

Systems and methods for group delivery, group counting and group pacing of ad delivery on the world wide web

InactiveUS20130144712A1Guaranteed delivery qualityIncrease contentAdvertisementsSingle entityAd serving

Through the utilization of group delivery, group counting and group pacing, an ad serving platform treats a grouping of ads as a standard unit despite the multiple ad unit components. The ad server platform paces and manages the flight of that grouped set of ads as a single entity. The ad server platform guarantees quality of delivery by only counting a qualified impression event when the group delivery has been successful, thereby opening this type of highly impactful advertising experience up to non-standard inventory sources, rather than relying on highly controlled content environments.

Owner:GLAM MEDIA

Clamping device for machine tool feeding

InactiveCN104175143AReduce labor intensityAvoid fatigue operationMeasurement/indication equipmentsPositioning apparatusMachine toolEngineering

The invention relates to a clamping device for machine tool feeding and belongs to the field of machining equipment. The clamping device comprises a fixture arranged on a working table of a machine tool, wherein a feeding device is arranged at a charging port of the machine tool; the fixture is glidingly connected with the working table and comprises two engaged clamp seats, and clamp seat driving devices are arranged on the clamp seats; the machine tool is further provided with a clamping control device; the clamping control device comprises a sensor and a controller, the sensor is arranged at the charging port of the machine tool, and the controller is connected with the sensor and the clamp seat driving devices respectively; workpieces can be sensed automatically and can be clamped and conveyed to a machining station of the machine tool.

Owner:徐秀

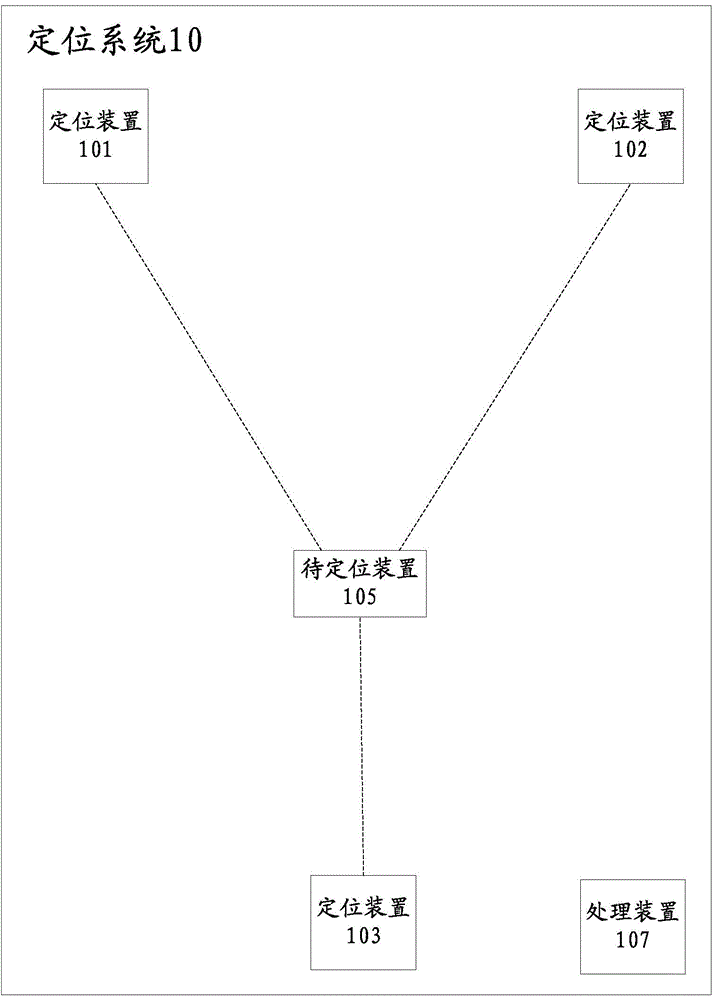

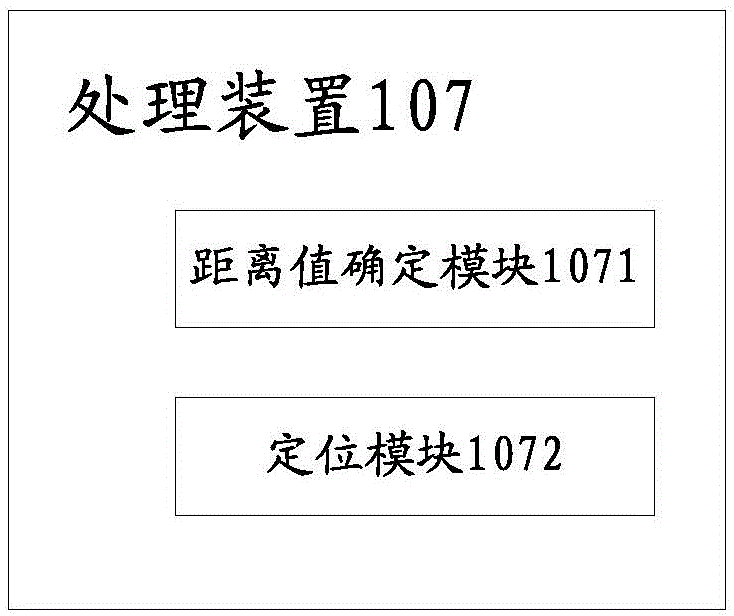

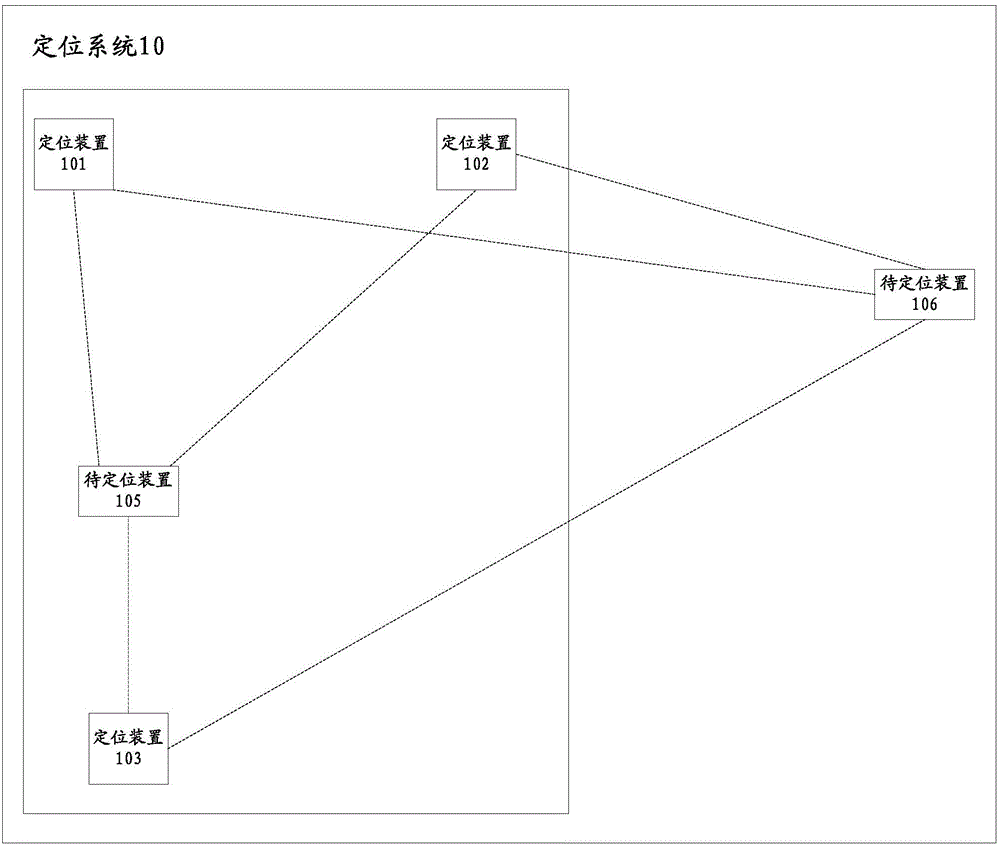

Multipoint positioning method and positioning system

The invention discloses a multipoint positioning method and a multipoint positioning system. A plurality of positioning devices are arranged, parameters of distances between the positioning devices and a device to be positioned are respectively measured by the positioning devices, the distance between the device to be positioned and each positioning device is determined by the parameters and positioning information is displayed, so that the position of the device to be positioned is accurately positioned. Accurate positioning on the device to be positioned in the measurement range of the plurality of positioning devices is implemented. meanwhile, to prevent the condition that signal intensity is low in a certain places or the device to be positioned is far away from a display device, according to the invention, the positioning information also can be sent to a relay server to be transferred so as to effectively ensure information transfer quality. High-accuracy positioning is guaranteed to be implemented in the complex environment.

Owner:NATIONZ TECH INC

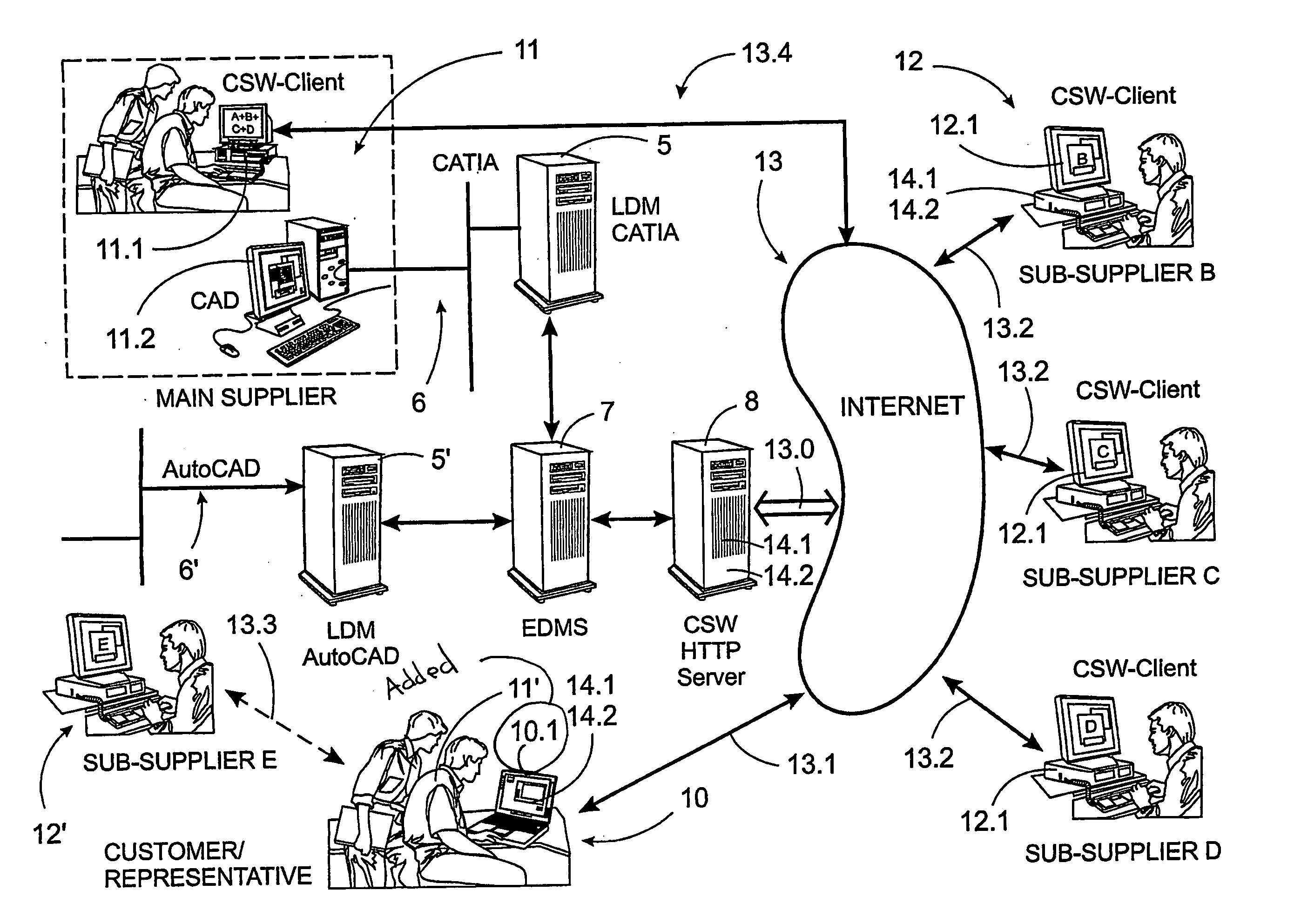

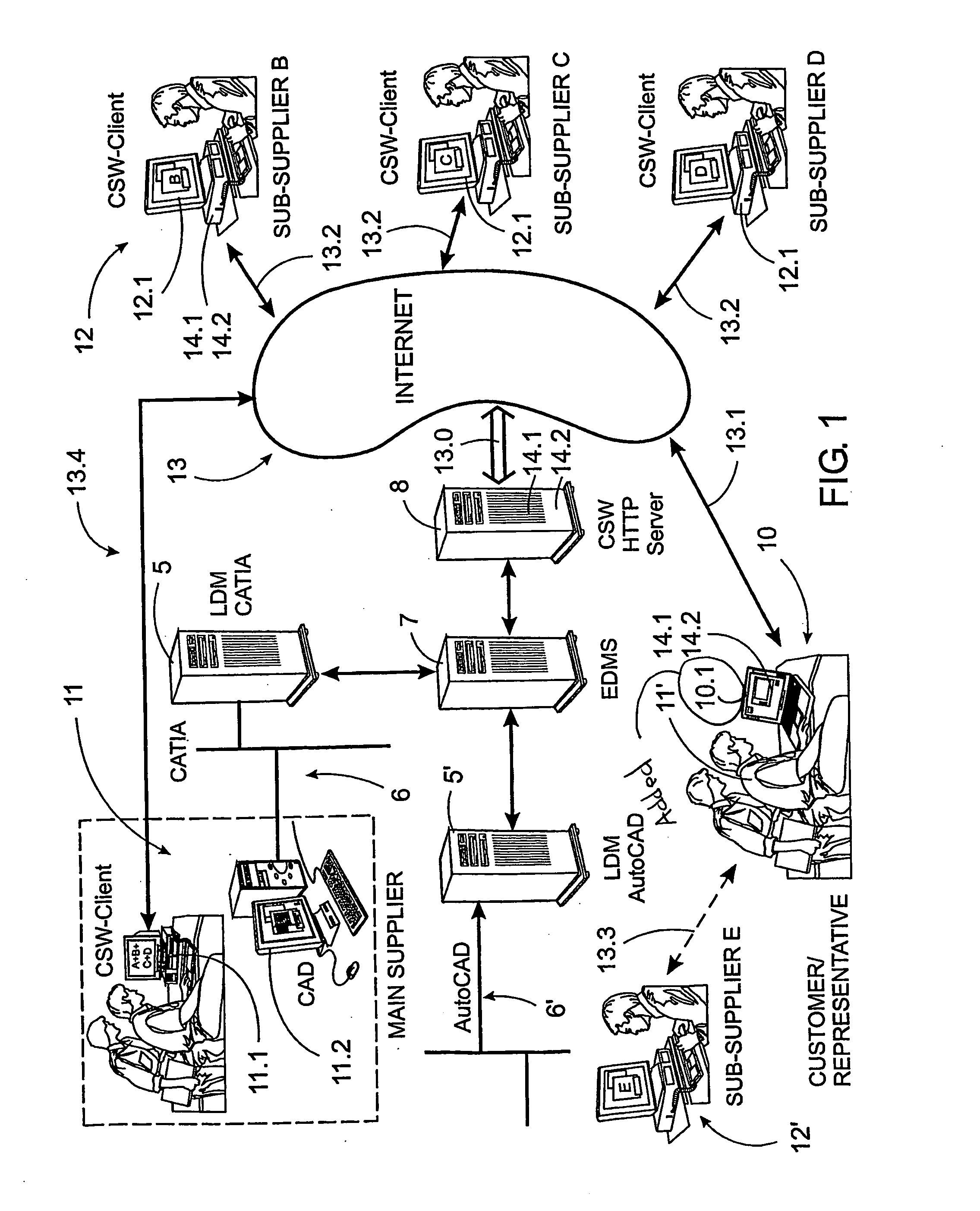

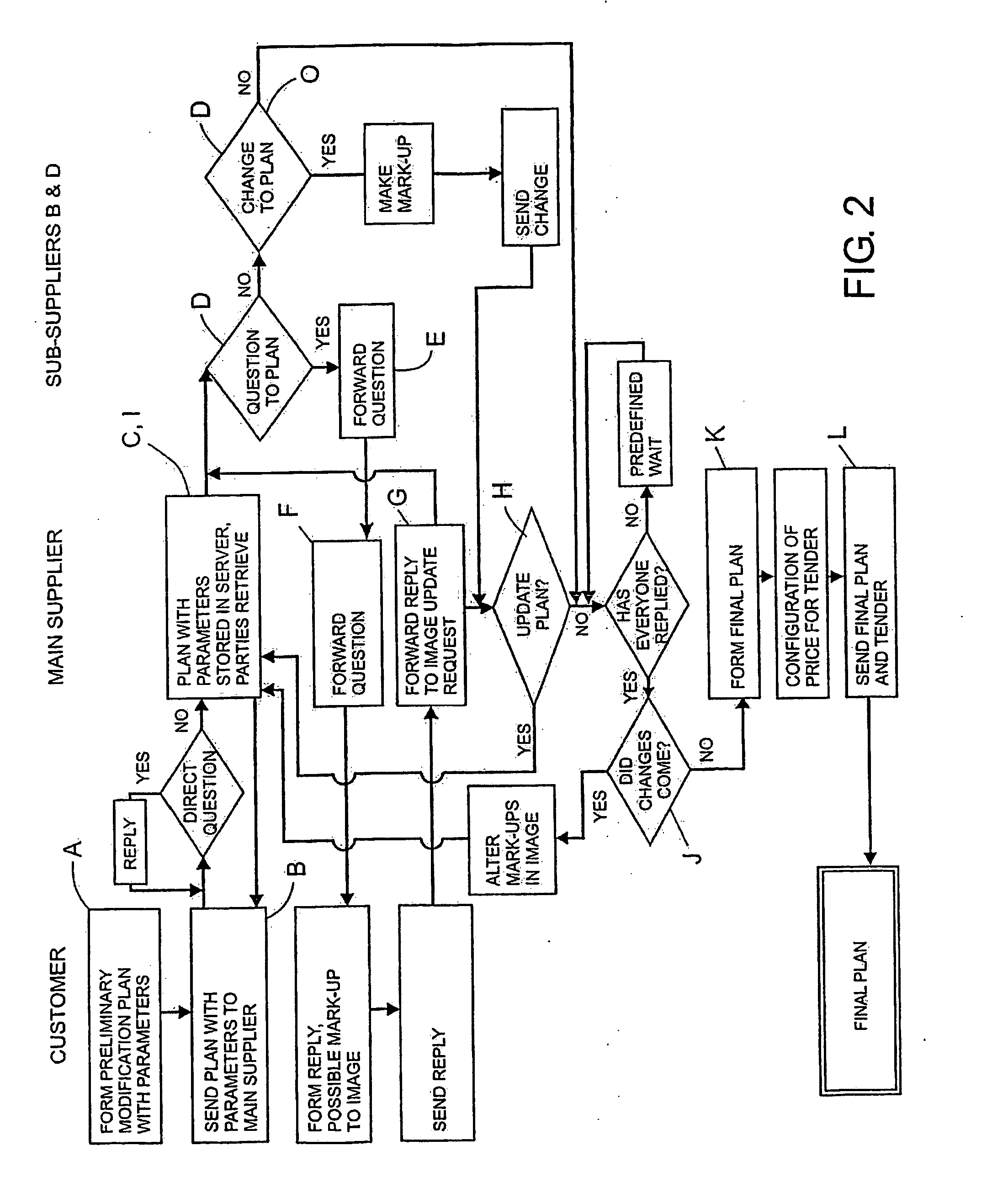

Modification planning arrangement

InactiveUS20050160354A1Solve the large amount of dataAvoid disadvantagesForecastingDigital differential analysersImage ViewProgram planning

A modification planning arrangement and method for a paper, board, finishing, or pulp machine, which includes as parties, a customer (10), a main supplier (11) and at least one sub-supplier (12), as well as a server linked to them over a telecommunications network. Each party has terminal equipment and software for viewing an image stored in the server and for communication in a data network. The image-viewing software has a mark-up function for attaching a mark-up to an image and for storing the mark-up in the server as its own mark-up file in connection with the image. The main supplier has a high-level CAD system to make and process an original drawing. The arrangement includes conversion and management software for the original drawings (CAD), for storing the drawings in concept form (HPGL, PDF) in a server (EDMS), and includes a mark-up data updating system, for distributing automatically to all parties.

Owner:VALMET TECHNOLOGIES INC

Rapid delivery industrial design work management method, platform and system

The invention discloses a rapid delivery industrial design work management method, platform and system. The method comprises the steps that a packet receiver registers a personal account and registerspersonal technical attribute information; the sender issues an industrial design project demand and hosts project cost; the server establishes a project workflow and a task group according to industrial design project requirements; the server executes the workflow and sends the sub-tasks in the task group to a user terminal of a packet receiver conforming to the technical attribute of the sub-tasks; the packet receiver sends an instruction of subtask application; the packet receiver completes task uploading and delivery results within the task deadline; the server notifies the packet sender to check and accept the delivery result; and the server integrates delivery results of all the task groups, informs the packet sender of finishing information, and pays the cost according to the workload of the finished sub-tasks, the packet sender and the packet receiver. According to the flexible and controllable workflow management method provided by the invention, a standardized and normalizedbusiness process is formed in the process of industrial design work, and rapid delivery is ensured.

Owner:上海夫卡实业发展有限公司

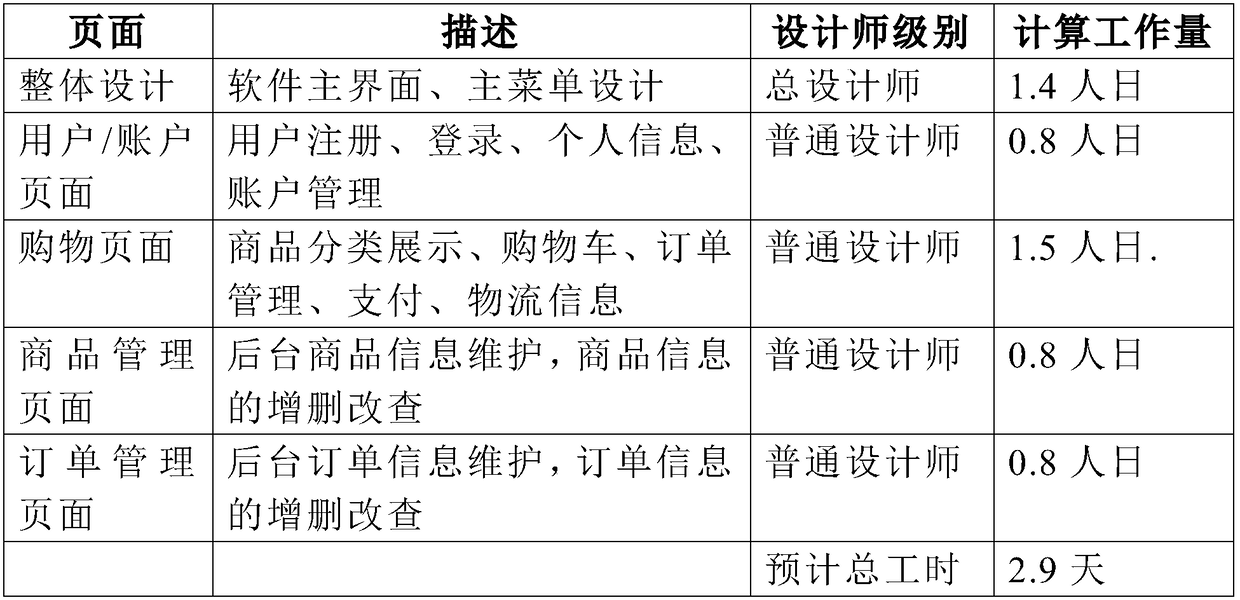

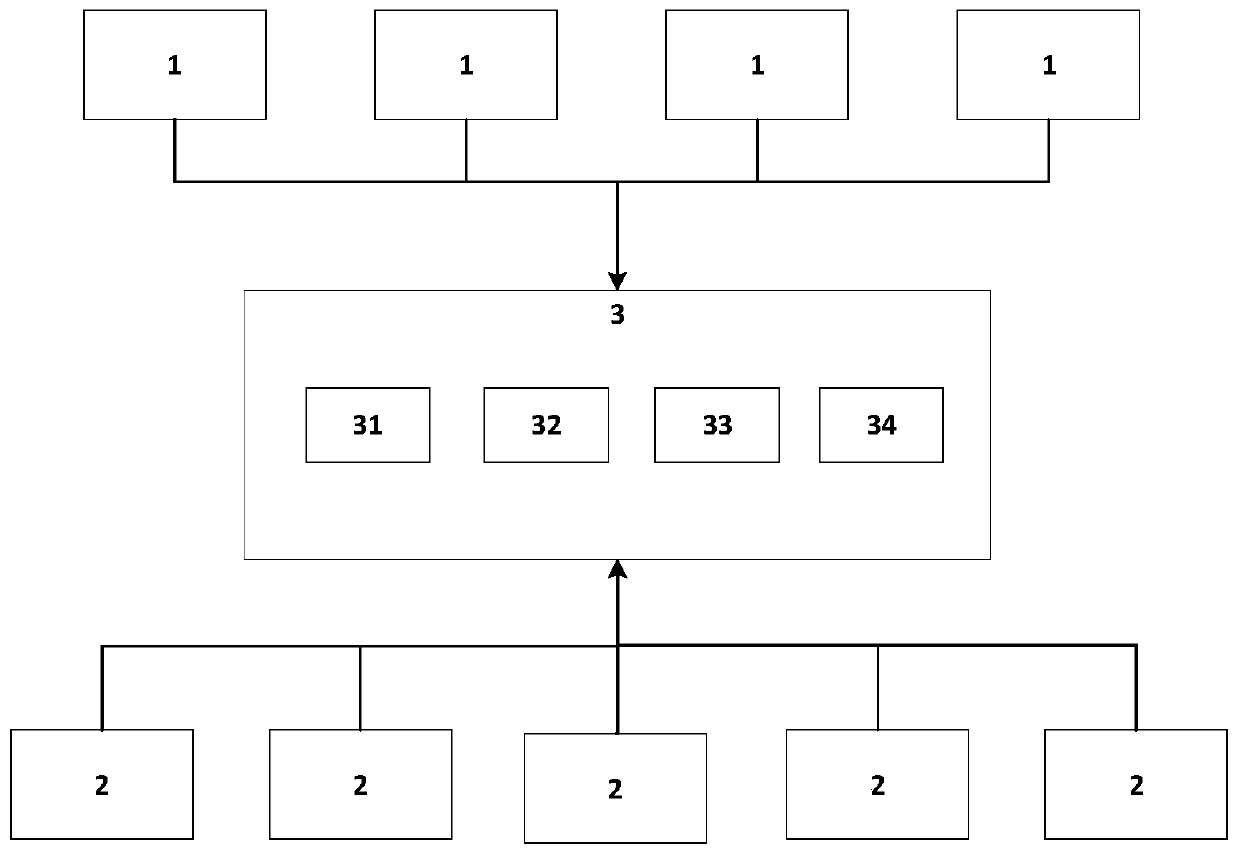

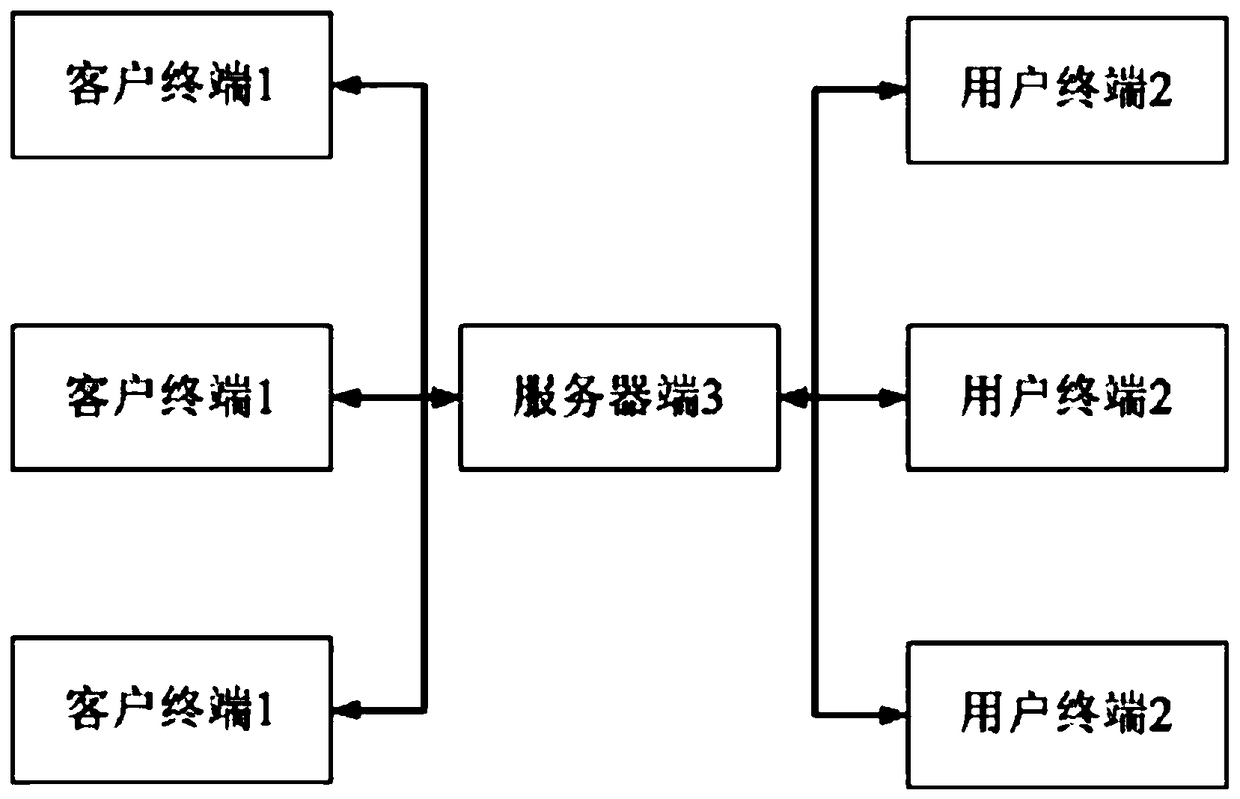

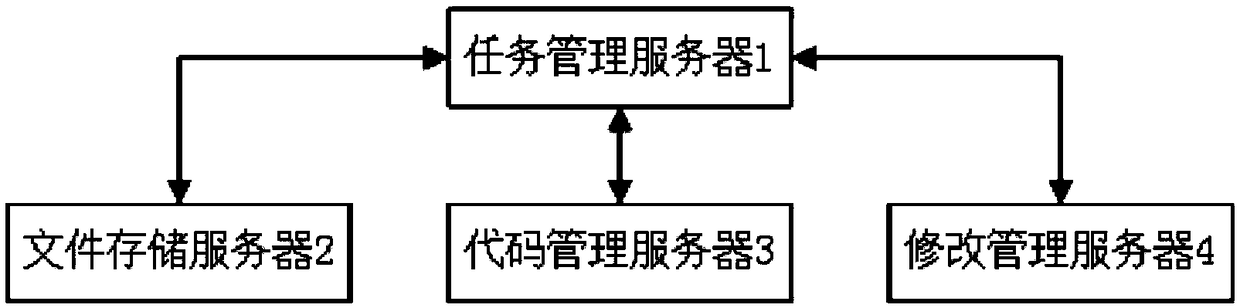

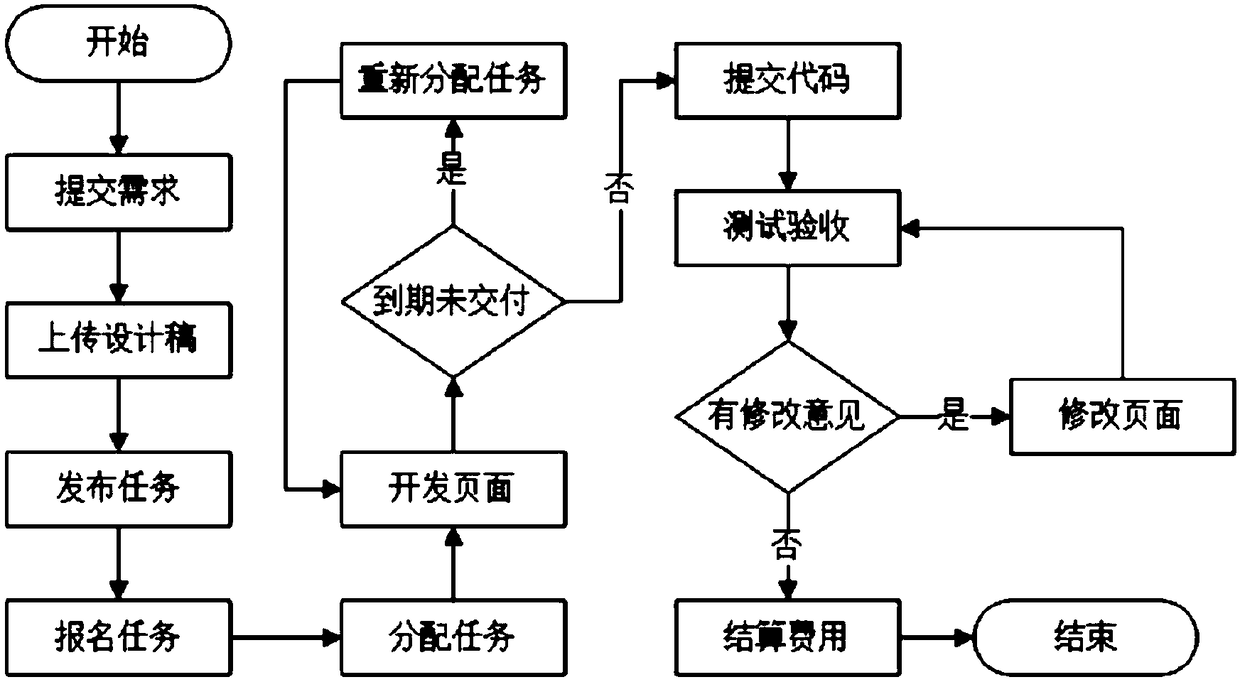

A front-end development platform that delivers fast in 24-hours

InactiveCN109101222AReduce communication workloadGuaranteed delivery qualitySoftware designWorkloadComputer science

The invention belongs to the technical field of computer application and discloses a 24-hour fast delivery front-end development platform. The platform comprises a system architecture and a working process, wherein the system architecture comprises a plurality of client terminals, a plurality of user terminals and a server terminal and the working process includes submitting requirements, uploading design manuscripts, publishing tasks, reporting tasks, assigning tasks, developing pages, reallocating tasks, submitting codes, testing acceptance, modifying pages, and settling expenses. On the onehand, the invention avoids repeated confirmation of a large number of conventional requirements and reduces the communication workload between the customer and the engineer by using the standardizedbusiness process and the development specification; on the other hand, it guarantees the overall quality of task delivery when multiple engineers are developing in parallel, which improves task development speed and ensures fast delivery within 24 hours.

Owner:武汉空心科技有限公司

Clamping tool for cam of half shaft

The invention discloses a clamping tool for a cam of a half shaft. The clamping tool comprises a base. A semicircular installing groove is formed in the base. An arc elastic clamping sheet is arranged at the left end of the installing groove, and an arc sliding clamping sheet is arranged on the right side section of the installing groove. The sliding clamping sheet comprises a cambered surface block connected with a sliding rod. The sliding rod is arranged in a sliding groove, and a reset stop block is fixed to the end, extending out of the sliding groove, of the sliding rod. The reset stop block is arranged in a reset groove. A reset spring is connected between the reset stop block and the closed end of the reset groove. The reset groove and the sliding groove are formed in the same groove body. A cambered surface matched with the cam is arranged on the end face of the end, extending out of the sliding groove, of the sliding rod. The section of the cam is an oval, one focus point of the cam is hinged to the base through a first hinge, the other focus point of the cam is hinged to one end of a connecting rod through a second hinge, and the other end of the connecting rod is hinged to a push-pull rod through a third hinge. According to the clamping tool, collisions caused by infirm fixing of the half shaft can be effectively reduced, and the half shaft transporting quality is guaranteed.

Owner:CHONGQING JINYUHENG TECH

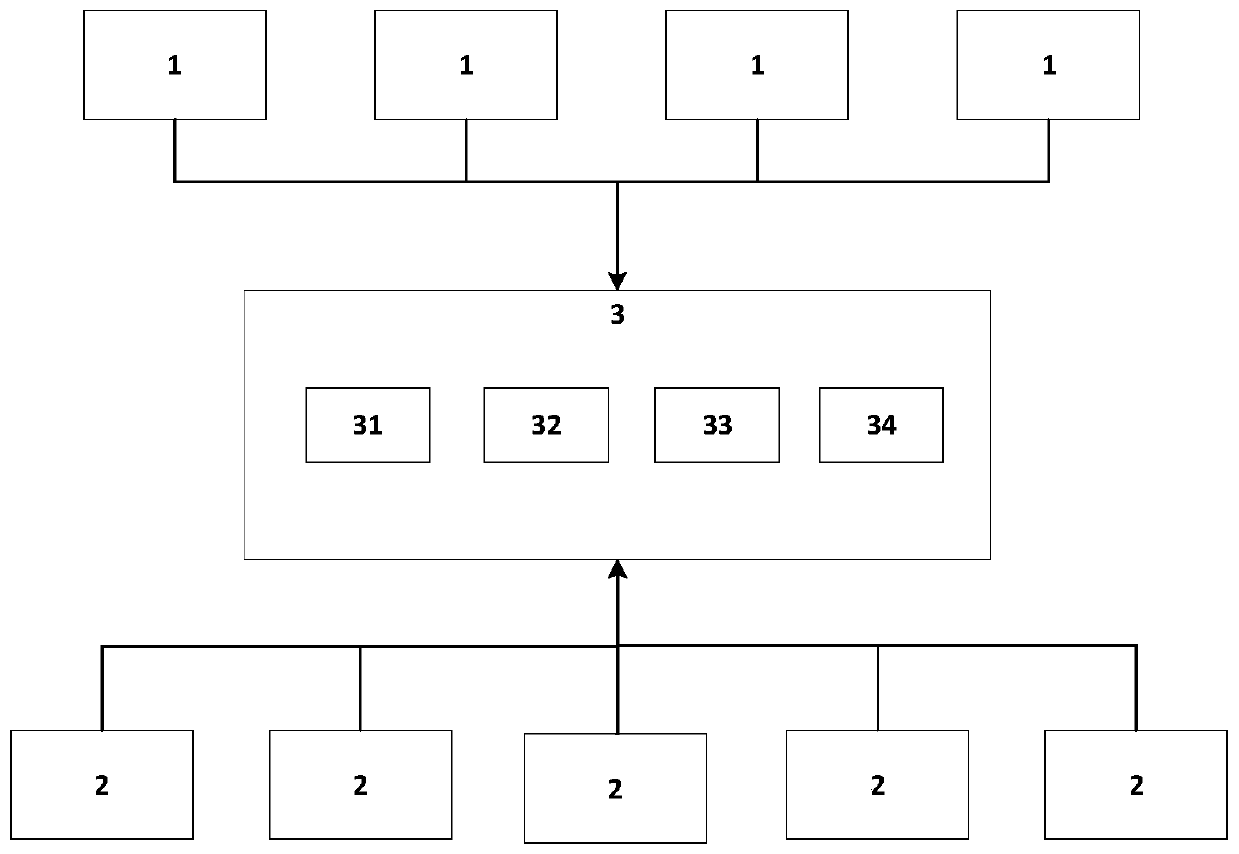

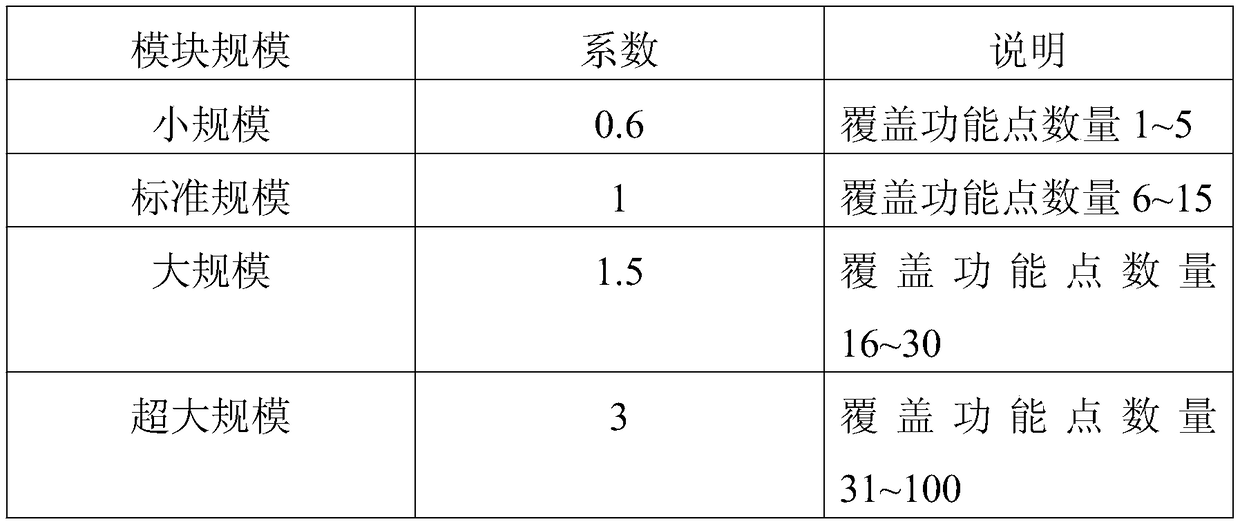

Development method and system based on module metering

InactiveCN109214645AGuaranteed delivery qualityFast deliverySoftware designOffice automationTask demandProject completion

The invention discloses a module-based development method and system. In the method, the server calculates the workload corresponding to the task and the overall development cost according to the working task demand sent by the client through the client terminal through a module measurement method, and divides the working task into a plurality of sub-tasks that can be completed by the engineer ina unit time according to the workload; and the server calculates the workload corresponding to the task and the overall development cost according to the module measurement method. Providing task information to the engineer user through the user terminal, and receiving an application instruction; assigning all sub-tasks to the engineers who sign up for the task for development, and setting the task deadline to ensure that all sub-tasks are completed within the task deadline; receiving the task code uploaded by the engineer; at the end of the task period, checking whether all the task code aresubmitted, if yes, sending a project completion message to the client terminal, the server carries out expense settlement according to the task, and sending a settlement message to the user terminal;otherwise, a project completion failure message is sent to the user terminal. The invention improves the development speed and ensures fast delivery.

Owner:武汉空心科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com