A pressure sleeve clamp for special-shaped angle bushings

A bushing and angle technology is applied in the field of pressing fixtures for special-shaped angle bushings, which can solve the problems that the installation quality of the special-shaped angle bushings cannot be effectively guaranteed, the work efficiency is low, and the marking accuracy is difficult to guarantee.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The principles and features of the present invention will be described below with reference to the accompanying drawings. The examples are only used to explain the present invention, but not to limit the scope of the present invention.

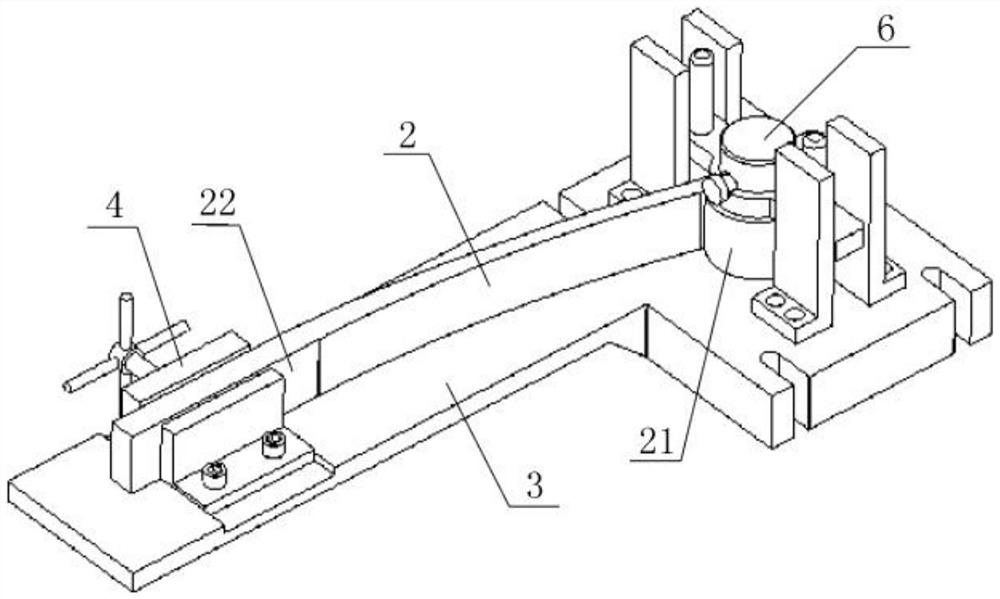

[0036] A pressure sleeve clamp for a special-shaped angle bushing, which is used to install the bushing 1 into the roll ear piece 2, and the roll ear piece 2 can be a leaf spring roll ear piece, or a guide arm roll ear piece, or The inner hole presses all the parts of the bushing. In this embodiment, the roll ear piece 2 is a leaf spring roll ear piece.

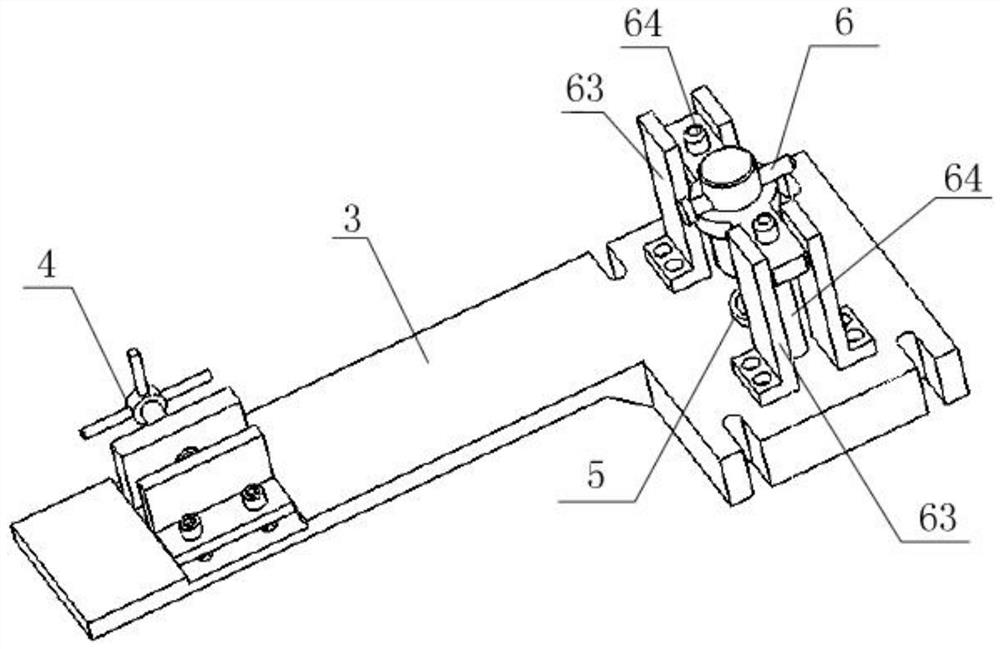

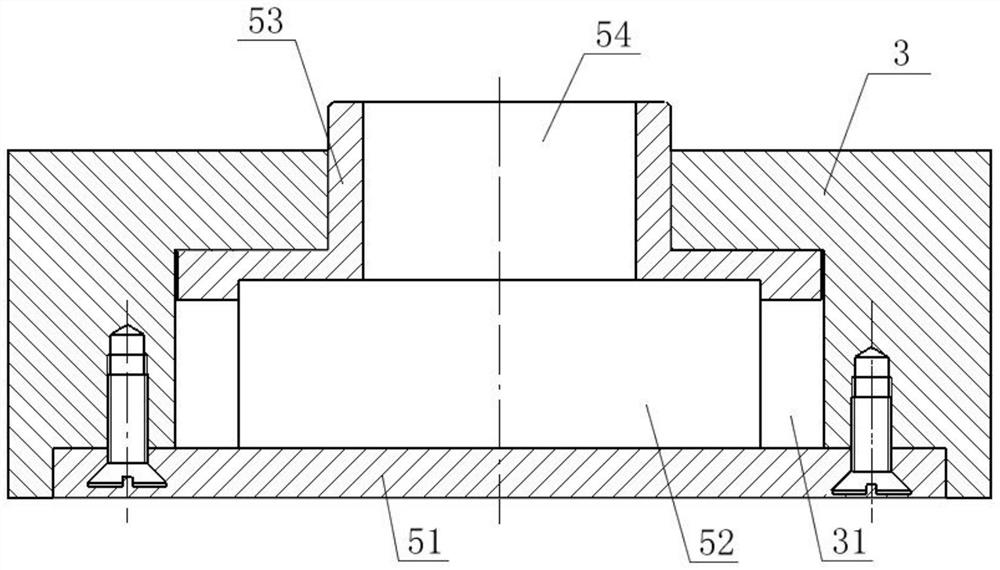

[0037] like figure 1 and figure 2 As shown, the sleeve pressing fixture in this embodiment includes a base plate 3 , a clamping device 4 , a positioning device 5 , and a pressing device 6 . The clamping device 4 and the positioning device 5 are respectively installed on both ends of the base plate 3 , the clamping device 4 clamps the straight section 22 of the single piece 2 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com