Rubber track raw material treatment device

A raw material processing and rubber crawler technology, which is applied in the rubber field, can solve the problems of processing and use, inability to carry out rubber mixing treatment, and inability to squeeze and mix rubber at the tip of the wedge block.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

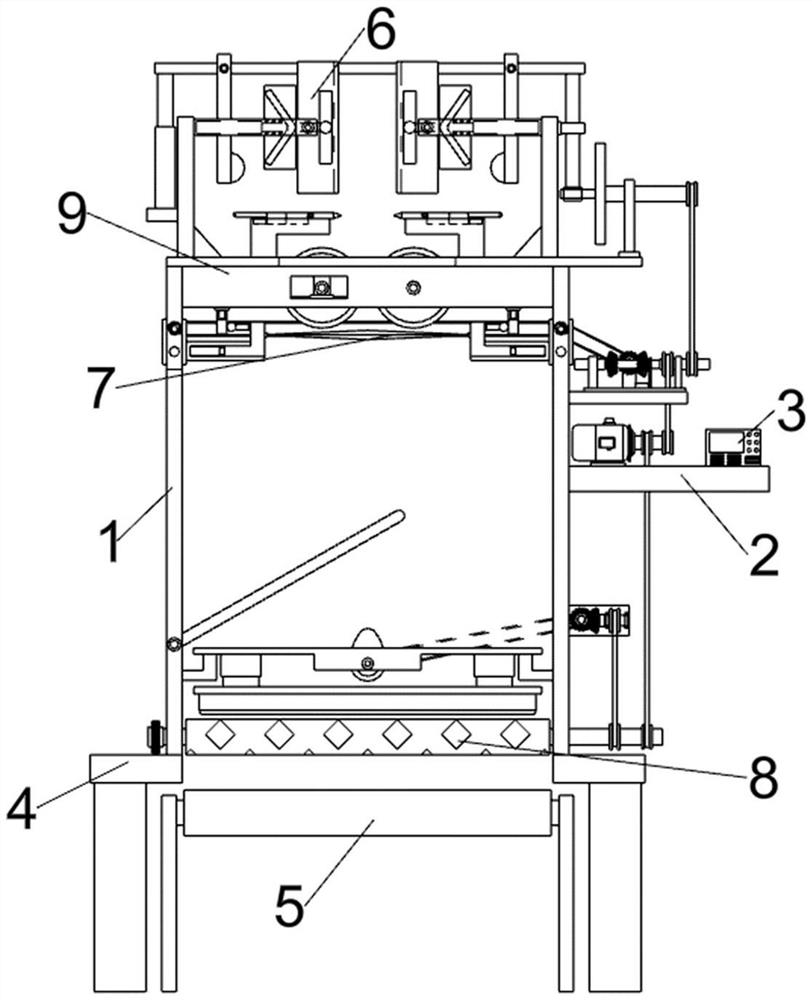

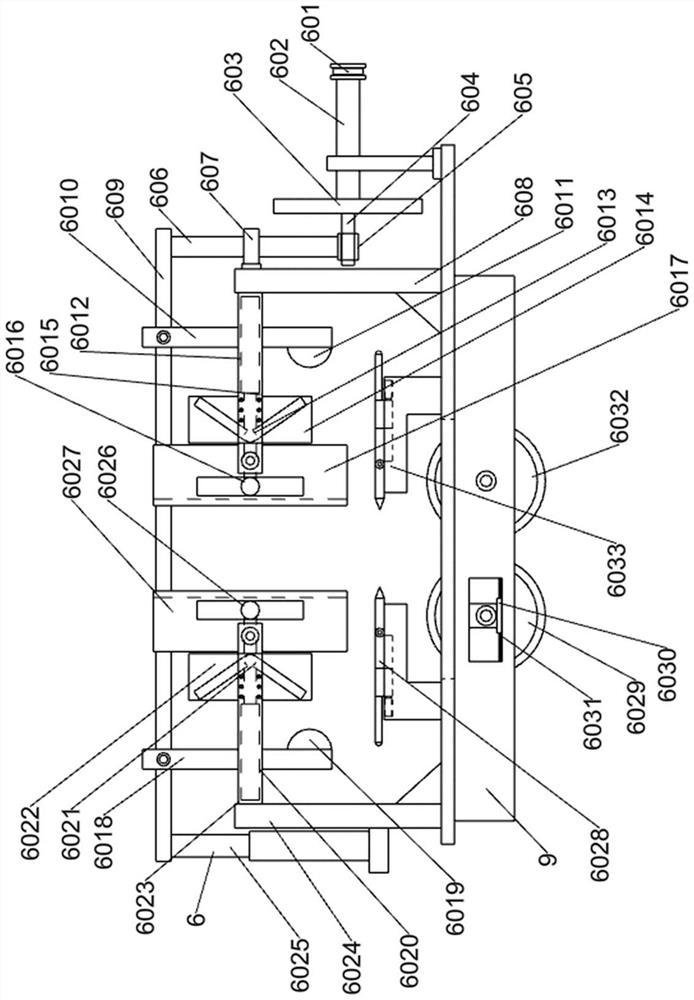

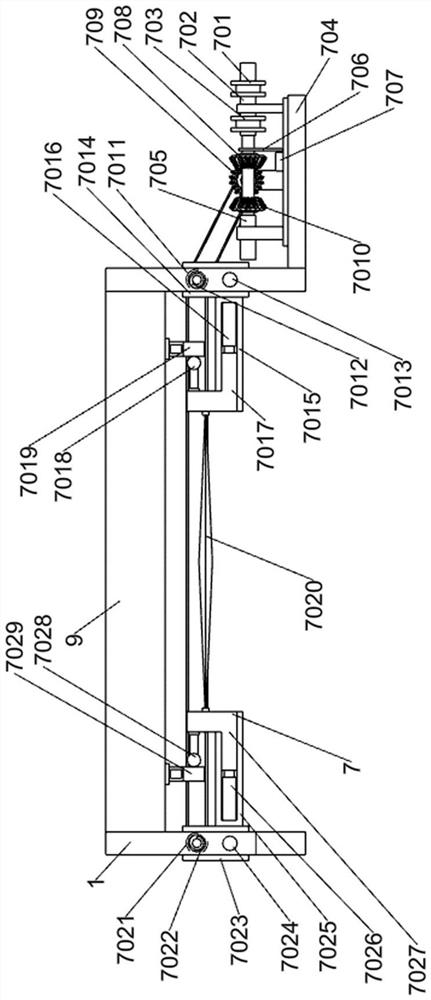

[0025] A rubber crawler raw material processing device, such as Figure 1-6 As shown, it includes separation processing cabin 1, frame connecting plate 2, operation control panel 3, supporting foot platform 4, independent conveyor belt 5, precise feeding mechanism 6, corner separation mechanism 7, refining mechanism 8 and top connection The platform 9; the separation treatment cabin 1 is bolted to the frame connecting plate 2; the bottom of the separation treatment cabin 1 is connected to the supporting foot platform 4; the bottom of the separation treatment cabin 1 is provided with an independent conveyor belt 5; The connecting platen 9 is connected; the operation control panel 3 is arranged above the frame connecting plate 2; the top connecting platen 9 is connected with the precise feeding mechanism 6; the precise feeding mechanism 6 is connected with the corner separation mechanism 7; the separation process The cabin 1 is connected with the corner separation mechanism 7; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com