A process for removing magnetic powder from oily steel plate with porous surface

A multi-porous, steel plate technology, applied in the direction of magnetic separation, cleaning method using tools, solid separation, etc., can solve the problems of difficult cleaning, low cleaning efficiency, difficult to clean, etc., to ensure the efficiency of degreasing and demagnetizing powder, improve The effect of improving the efficiency of magnetic output and improving the efficiency of degreasing and demagnetizing powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

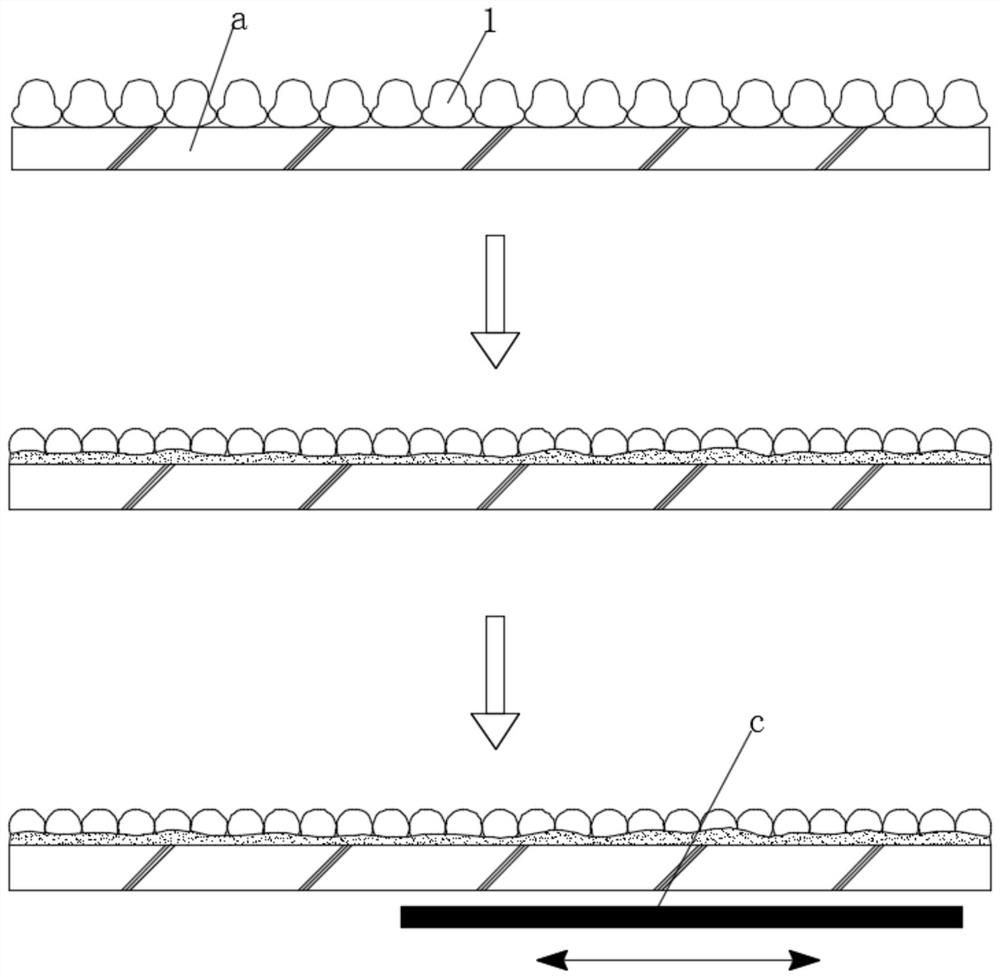

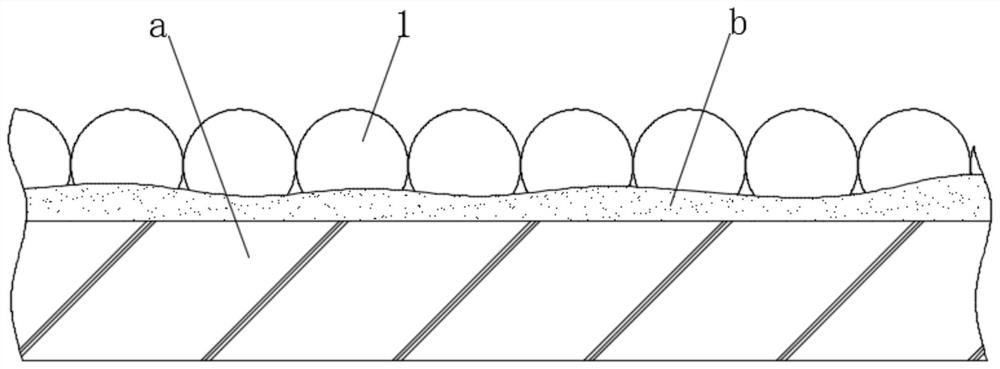

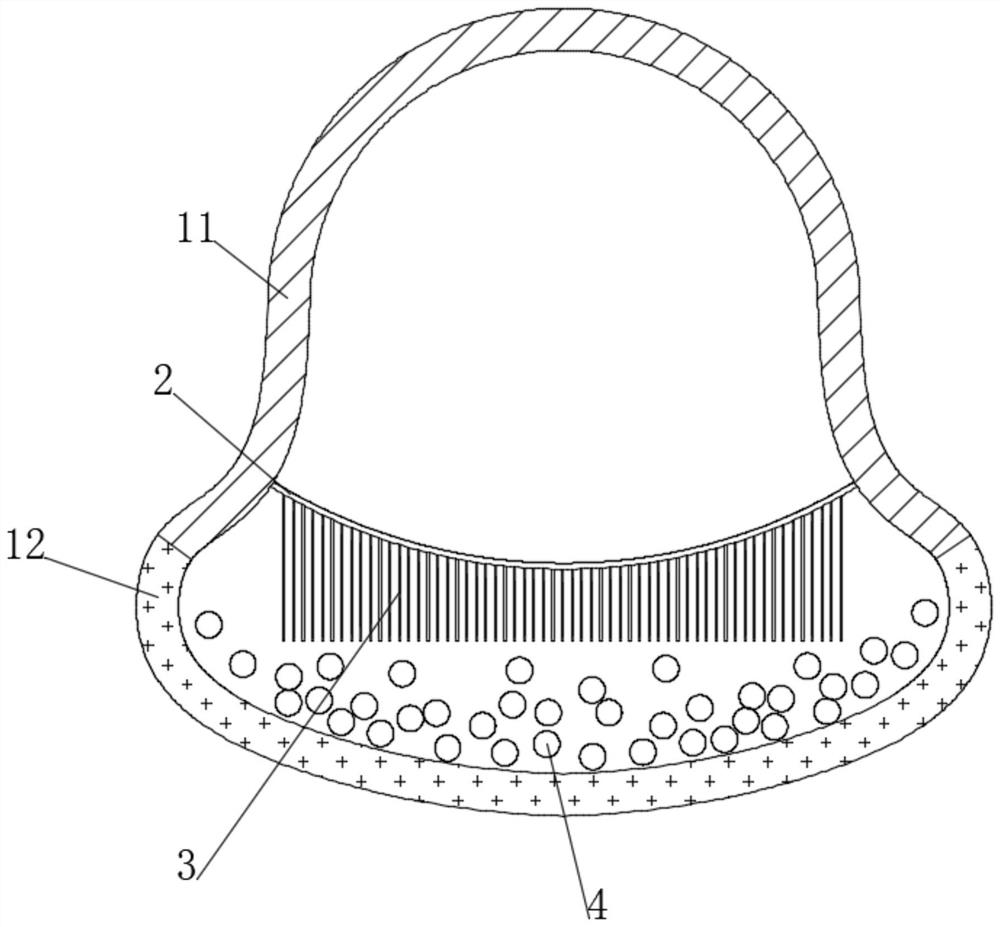

[0045] see Figure 1-2 , in the figure, a represents the steel plate, b represents the outflowing cleaning agent, and c represents the magnetic plate, a process for removing magnetic powder from an oily steel plate with a porous surface, including the following steps:

[0046] S1. First remove the obvious impurities on the surface of the steel plate;

[0047] S2, then evenly sprinkle the embedded brush ball 1 containing cleaning agent on the surface of the oily steel plate;

[0048] S3, heating to melt the lower end surface of the embedded brush ball 1, so that the cleaning agent inside flows to the surface of the oil-containing steel plate and penetrates into the pores on the surface;

[0049] S4. After a period of time, pass through the magnetic plate on the lower surface of the oily steel plate to drive the rest of the embedded brush balls 1 to move in close contact on the surface of the oily steel plate to clean the surface of the oily steel plate.

[0050] The area of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com