Injection mold stripper plate mounting structure

An installation structure and injection mold technology, applied in the field of injection molding, can solve the problems of limited connecting rod travel, inconvenient connection and installation of injection mold and injection molding machine, and affect stripping, so as to facilitate connection and installation, ensure the quality and stability of stripping Sex, good quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

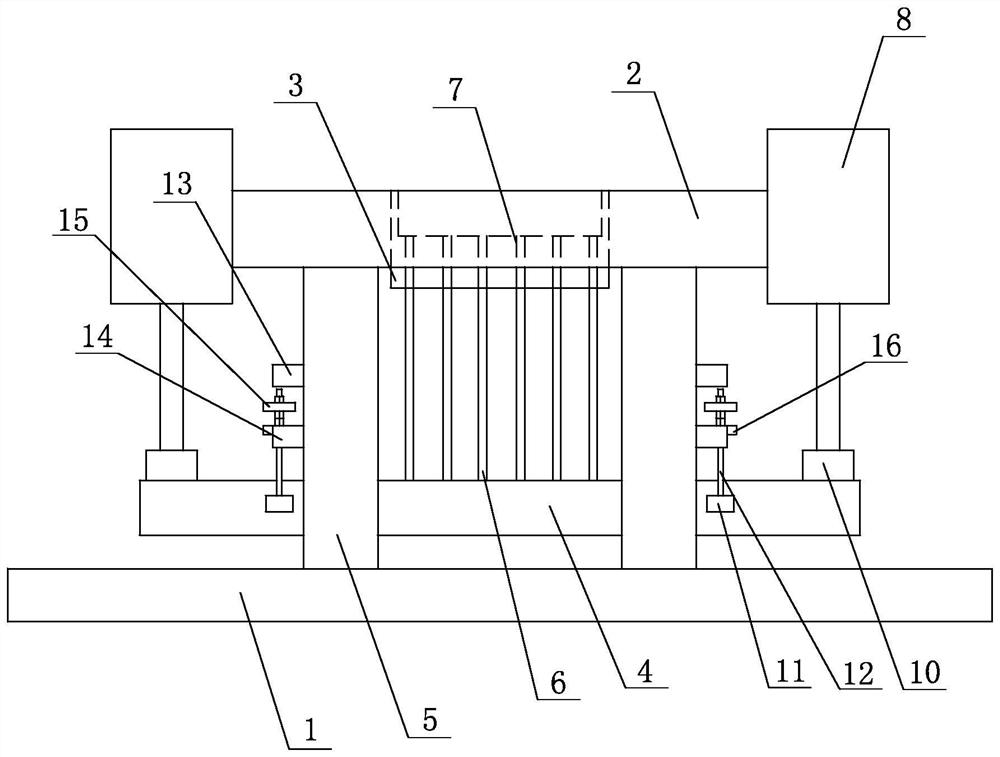

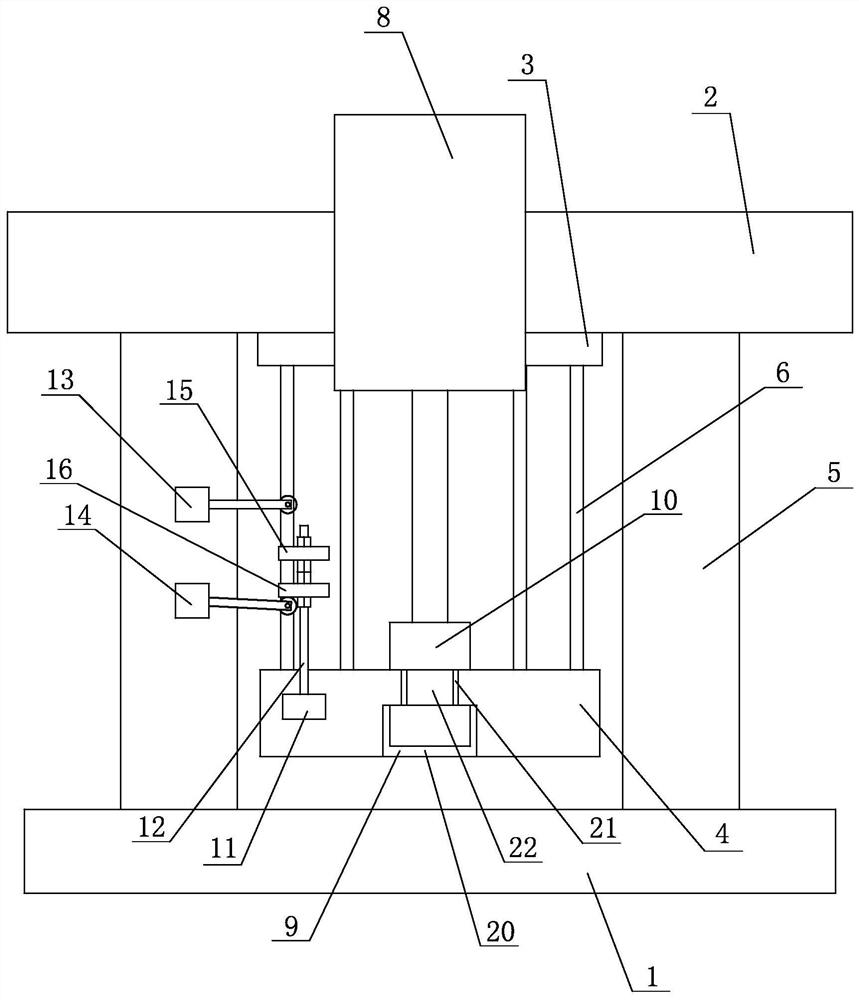

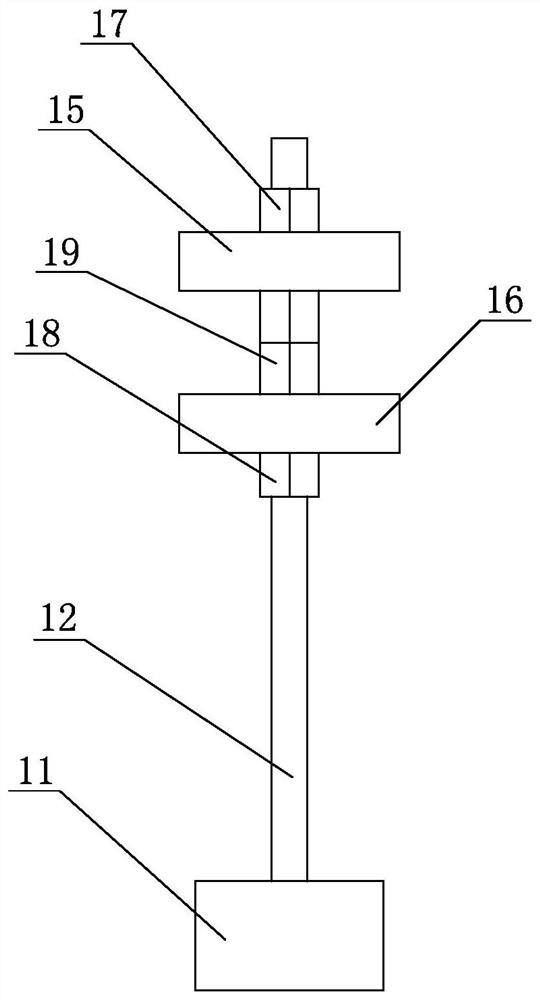

[0021] Embodiment one: see Figure 1~3 As shown, a stripping plate installation structure for an injection mold includes a bottom plate 1, a mounting plate 2, a die 3 and a stripping plate 4, the die is installed inside the mounting plate, and the bottom surface of the mounting plate has four The corners are respectively connected to the top surface of the bottom plate via a vertical plate 5, the stripper plate is installed between the bottom plate and the installation plate, and multiple groups of ejector rods are arranged on the top surface of the support plate 6. There are multiple sets of stripping holes 7 in the die, the top of each set of ejector rods is inserted into a set of stripping holes, and the left and right sides of the mounting plate are respectively provided with a The hydraulic cylinder 8, the left side and the right side of the stripper plate are respectively arranged on the left side and the right side outside the installation plate;

[0022] The left side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com